Product Details

Africa 686 IBR roof sheet making machine can make IBR sheets in 0.3 to 0.8mm thick . It's widely used in whole africa market .

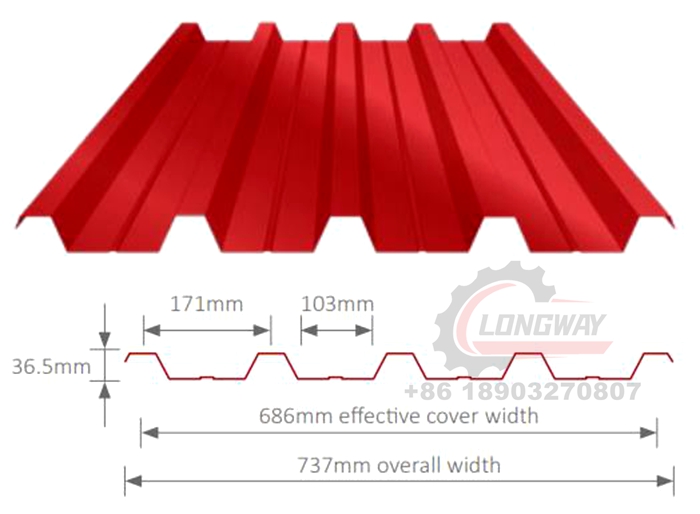

The trapezoidal roof sheet has a ribbed trapezoidal-shape pattern across the panel. Trapezoidal rib roofs are popular with producers because the shape makes them very material-efficient (a high strength-to weight ratio). This makes a very cost-effective profile. The shadows of the trapezoidal shapes offer clean lines whether installed vertically, diagonally, or horizontally.

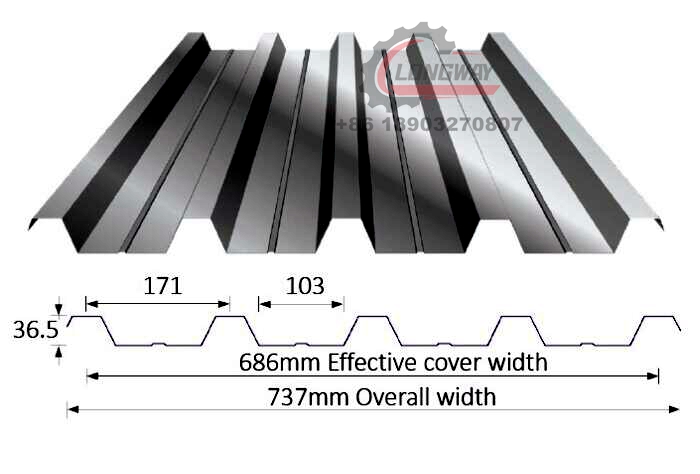

Profile drawing for reference:

Technical Farameters

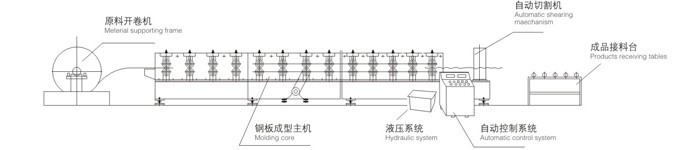

Processing Flow

|

Raw Material |

Coil Type |

PPGI,PPGL,GI |

|

Width |

914/925mm |

|

|

Thickness range |

29-22 Gauge (0.3-0.6mm) |

|

|

Power Requirement

|

Voltage |

380v/3ph/50hz(Customized) |

|

Main Motor power |

4+4kw |

|

|

Cutter power |

4kw |

|

|

Forming speed |

15-20m/min |

|

|

Machine Frame |

350mm H Beam Structure |

|

|

Thickness of structure |

18 mm Welded Steel Middle Support Plate |

|

|

Forming shaft |

75mm solid shaft with heat treatment |

|

|

Material Of Rollers |

High Grade 45# Forged Steel |

|

|

Forming stations |

14-18 rows Rolling Type: Separate rolling design concept, It can release Internal stress from the fheets, Then the sheet will be in good shape and high precision |

|

|

Transmission Way |

Chain drive 1 inch (Double Chain) |

|

|

Type of cutting |

Hydraulic Pillar type and length-set cutting |

|

|

Control system |

PLC Delta and Inverter Delta |

|

|

Screen |

Touch screen |

|

|

Dimension(Approx) |

7.5m×1.5m×1.2m |

|

|

Total weight (Approx) |

4.6T |

|

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

This series of the profile is designed to be economical roofing panels for residential, industrial, and commercial projects.

A minimum of 0.30mm and a maximum of 0.7mm gives more resilience to damage.

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display