Door Industry Forming Machine

Door roll forming machines offer several advantages in the manufacturing of doors. They enable efficient and cost-effective production of door components with high precision and consistency. By automating the forming process, these machines reduce labor costs and minimize material waste. Additionally, they allow for customization and flexibility in design, accommodating various door sizes, styles, and specifications. Overall, door roll forming machines play a crucial role in the door manufacturing industry, providing manufacturers with the tools they need to produce high-quality doors efficiently and competitively.

Door Roll Forming Machine Introduction

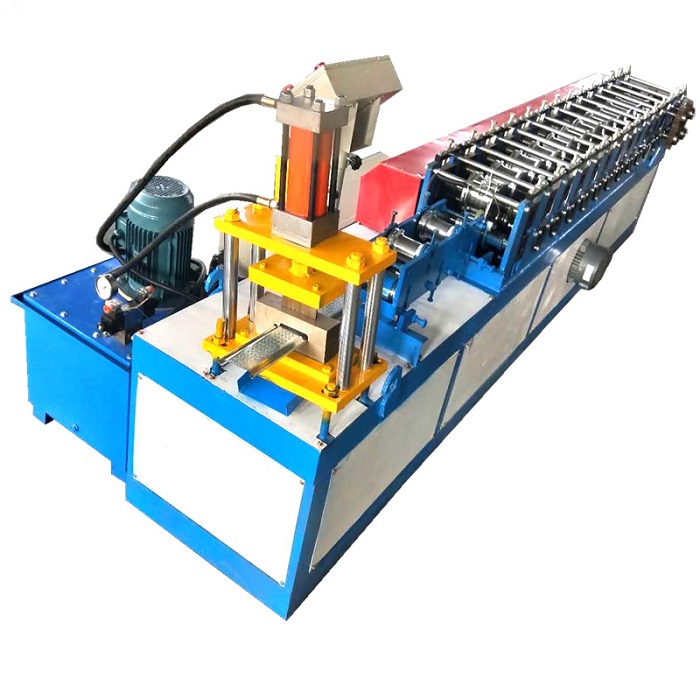

A door roll forming machine is a specialized piece of equipment used in the manufacturing process of doors, particularly metal doors such as steel or aluminum doors. This machine utilizes a roll forming process to shape metal sheets into the desired profiles and components required for constructing doors. Here's an overview of the components and functions of a typical door roll forming machine:

Uncoiler: The process begins with a decoiler or uncoiler, which holds the metal coil that will be fed into the roll forming machine. The coil unwinds as the forming process progresses.

Feeding System: The metal coil is fed into the machine through a feeding system, which ensures a smooth and continuous supply of material for the roll forming process.

Roll Forming Stations: The heart of the door roll forming machine is the series of roll forming stations. Each station consists of a set of rollers arranged in sequence, which gradually shape the metal sheet into the desired profile of the door component. These rollers can be customized to create various shapes and features, such as panels, rails, stiles, and grooves.

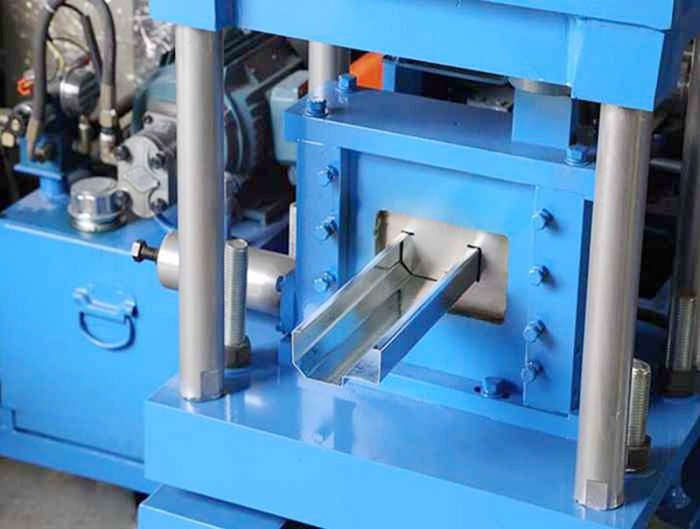

Cutting Mechanism: Once the metal sheet has been formed into the desired profile, a cutting mechanism such as a flying cutoff or a stationary shear cuts the formed components to the required lengths. This ensures precise and uniform dimensions for each door component.

Embossing or Punching: Some door roll forming machines may include additional stations for embossing or punching holes, patterns, or designs onto the formed components. This adds decorative or functional features to the doors, such as panel designs or lockset cutouts.

Stacking or Packaging: Finished door components are stacked or packaged for transportation and further assembly. Stacking systems may include conveyors, stackers, or palletizers to organize and stack components efficiently.

Control System: Modern door roll forming machines are equipped with computerized control systems that regulate the speed, tension, and other parameters of the forming process. Operators can monitor and adjust settings through a user-friendly interface, ensuring precise control and consistent quality in production.