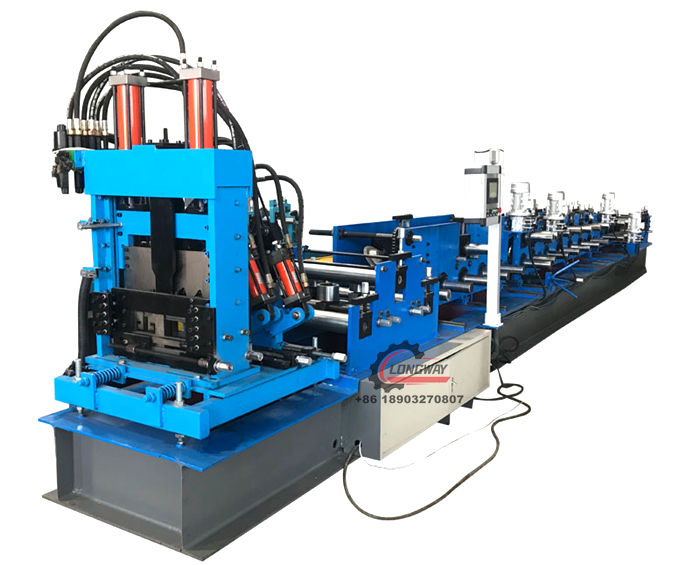

C & Z purlin Machine

The China CZ purlin roll forming machine represents a pinnacle of modern engineering, designed to streamline the production of CZ-shaped steel purlins with unparalleled efficiency and precision. Engineered with cutting-edge technology and robust construction, this machine embodies reliability and versatility, catering to the diverse needs of the construction industry. Its automated operation seamlessly transforms raw materials into high-quality CZ purlins with consistent dimensions and profiles, ensuring superior structural integrity and aesthetic appeal in every output. From rapid production speeds to customizable design options, the China CZ purlin roll forming machine stands as a testament to innovation, empowering manufacturers and contractors to meet project demands with utmost efficiency and quality.

How To Choose A Good CZ Purlin Roll Forming Machine

Choosing a good CZ purlin roll forming machine involves several key considerations to ensure that it meets your specific production needs and quality standards. Here's a step-by-step guide:

Define Your Requirements: Determine the specifications of the CZ purlins you need to produce, including dimensions, thickness, material type, and production capacity. Understanding your requirements will guide your selection process.

Research Reliable Manufacturers: Look for reputable manufacturers with a track record of producing high-quality roll forming machines. Check customer reviews, testimonials, and industry certifications to assess their reliability and reputation.

Evaluate Machine Features: Compare the features and capabilities of different CZ purlin roll forming machines. Look for features such as high-speed production, automated control systems, adjustable tooling, and compatibility with various materials.

Inspect Build Quality: Examine the build quality of the machine, including the frame, rollers, cutting mechanism, and control systems. Ensure that the machine is sturdy, durable, and built to withstand long-term use in demanding production environments.

Consider Customization Options: Choose a CZ purlin roll forming machine that offers customization options to meet your specific requirements. Look for machines with adjustable parameters, quick-change tooling, and flexible configurations to accommodate different purlin profiles and sizes.

Assess Production Efficiency: Evaluate the production efficiency of the machine, including its speed, accuracy, and reliability. Choose a machine that can produce CZ purlins efficiently while maintaining consistent quality and minimizing material wastage.

Check After-Sales Support: Consider the after-sales support provided by the manufacturer, including warranty coverage, technical support, and spare parts availability. Ensure that the manufacturer offers timely assistance and support to address any issues or maintenance needs that may arise.

Review Costs and ROI: Compare the costs of different CZ purlin roll forming machines, taking into account factors such as upfront investment, operating expenses, and potential return on investment (ROI). Choose a machine that offers the best balance of cost-effectiveness and long-term value for your business.