Product Details

Light steel ceiling CU channel roll forming machine is widely used in ceiling and drywall construction. Compared with cement construction and wooden construction,steel frame is more light and durable.Thanks to these advantages,C channel roll forming machines and U channel roll forming machines are welcomed in the construction field.

Ceiling Channel Roll Forming Machine Advantages

1. High speed. Our high speed C/U/Omega stud channel roll forming machine speed can up to 40m/min.

Normally, C/U/Omega stud channel forming machine's speed is around 20-25m/min .

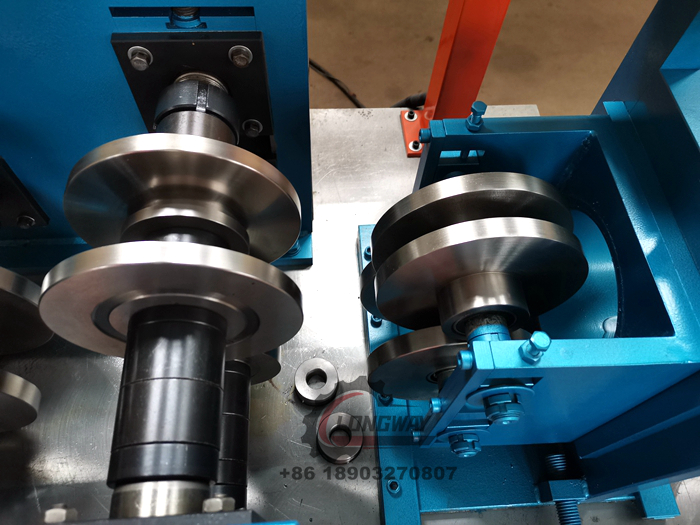

2. High durablity. Our rollers adopt the Cr 12 with quenched treatment,this is the best material for rollers.

3. High automatic. high speed C/U/Omega stud channel making machine adopts PLC systerm.

User can set production quantity, production speed on control cabinet.

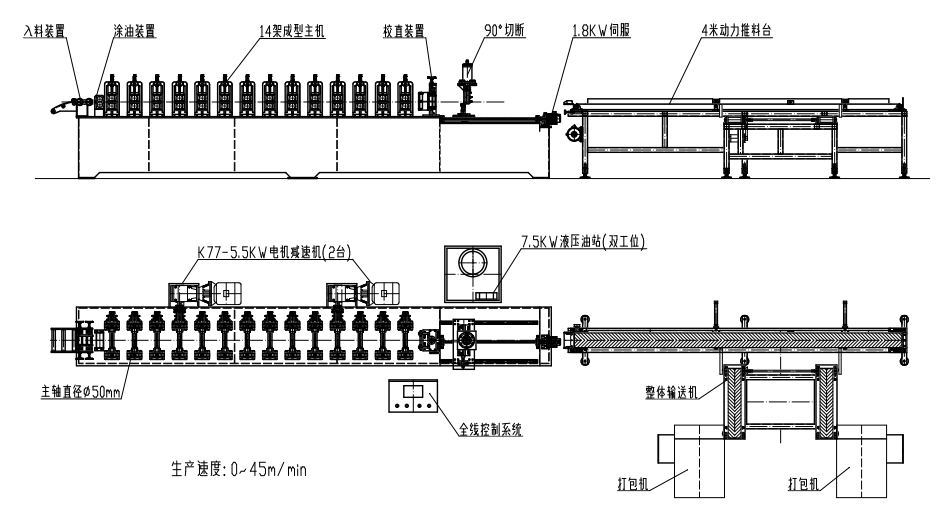

Ceiling Channel Roll Forming Machine Components

Roll forming stations: These stations consist of sets of rollers and dies arranged in sequence to progressively shape the metal coil into the desired profile.

Cut to length machine: Cutting blades integrated into the machine can precisely trim the formed channels to the required length.

Metal sheet punching machine: These units can punch holes or slots into the channels at specified intervals for mounting purposes or to accommodate accessories.

Material feeding system: Automated systems feed metal coils into the machine consistently, ensuring uninterrupted production.

Control system: Modern U channel roll forming machines are equipped with advanced control systems, often featuring touchscreens or computer interfaces, to set parameters, monitor production, and troubleshoot issues.

Adjustable tooling: Some roll forming machine for sale offer the flexibility to adjust the tooling to produce different sizes or profiles of ceiling channels, allowing for versatility in manufacturing.

Overall, a ceiling channel roll forming machine plays a crucial role in streamlining the production of ceiling components, contributing to the efficiency and quality of suspended ceiling systems used in various construction projects. As a roll forming equipment manufacturer,we provide products with reasonable ceiling channel machine price.

Ceiling Channel Roll Forming Machine Applications

Suspended Ceilings: Ceiling channels are commonly used in suspended ceiling systems where they provide support for ceiling tiles or panels. These systems are widely used in commercial buildings, offices, schools, hospitals, and other structures to conceal wiring, plumbing, and HVAC ducts while improving aesthetics and acoustics.

Drywall Framing: Ceiling channels are an integral part of drywall framing systems such as drywall roll forming machine used to construct interior walls and ceilings. They provide structural support for attaching gypsum boards or drywall panels, creating partition walls, and dividing interior spaces in residential, commercial, and industrial buildings.

Partition Walls: In office buildings, retail spaces, and other commercial settings, ceiling channels are utilized in partition wall systems such as cladding roll forming machine for sale to divide large areas into smaller rooms or cubicles. These systems offer flexibility, allowing for easy reconfiguration of space as needed.

Lighting Fixtures: Ceiling channels can also be used to mount lighting fixtures, such as fluorescent lights or LED panels, in both residential and commercial settings. The channels provide a stable base for securely attaching the fixtures to the ceiling while also accommodating wiring and electrical connections.

Decorative Applications: In addition to their functional roles, ceiling channel roll forming machine can be used for decorative purposes in architectural designs. They may be incorporated into ceiling designs to add visual interest, create geometric patterns, or define different areas within a space.

Soundproofing and Insulation: Ceiling channels can be part of systems designed to improve soundproofing and thermal insulation in buildings. By incorporating sound-absorbing materials or insulation batts between ceiling channels, these systems help reduce noise transmission and enhance energy efficiency.

Exterior Applications: In some cases, ceiling channel roll forming machine may also be used in exterior applications, such as soffits or eaves, to provide structural support and enhance the appearance of buildings' exteriors.

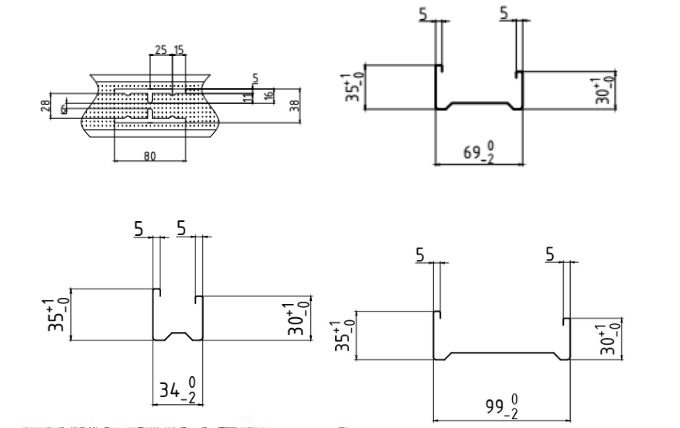

Here are some drawing profiles for your reference:

Technical Farameters

Processing Flow

|

Series

|

Details

|

Parameter

|

Comment

|

|

Material

|

Raw material

|

Steel

|

Customer confirmed

|

|

Material thickness

|

0.4-0.6 mm

|

||

|

Decoiler

|

Structure

|

Manual passive type

|

The standard one to match the production line

|

|

Single head type

|

|||

|

Loading capacity

|

1.5 Tons

|

||

|

Coil inner diameter

|

450-550 mm

|

||

|

|

Guiding device

|

Placed on the machine by seller

|

|

|

Rolling shaft material

|

45# STEEL

|

|

|

|

Shaft diameter

|

50 mm

|

|

|

|

Roller material

|

GB-Cr12

|

|

|

|

Rolling station

|

12 stations

|

|

|

|

Work speed

|

40 m/min

|

|

|

|

Machine structure

|

Vertical memorial arch frame

|

|

|

|

Machine basic frame

|

Steel plate welded

|

|

|

|

Bearing

|

Roller bearing

|

Famous brand of Harbin

|

|

|

Work power

|

4 kw

|

|

|

|

Transmission

|

By gear

|

With cover

|

|

|

Safety cover

|

available

|

|

|

|

Appearance

|

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

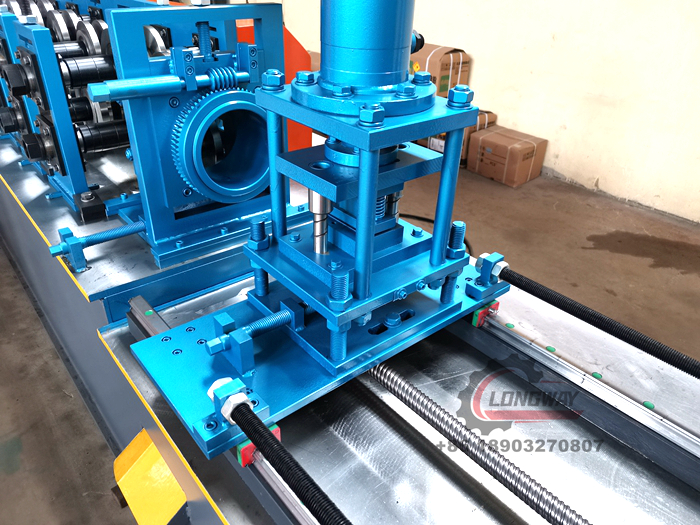

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

Non-composite conditions are common in all structures. When the gypsum board stops at the ceiling level, but the stud continues to the deck, it is a non-composite condition. Wall framing with Deflection Track, Resilient Channel (RC) or Sound Clips is a non-composite design since the screws attaching the gypsum board are not directly attached to the framing or top track. While there may be advantages to contacting Technical Services or a Design Professional, many conditions can be covered by limiting heights tables shown in this catalog .

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display