Product Details

Wall Cladding Machine QUADRO 25X40 is designed with an overlap system that allows its installation both horizontally with visible fixings. Cladding sheet has the feature of continuous, homogeneous and orthogonal modulation.

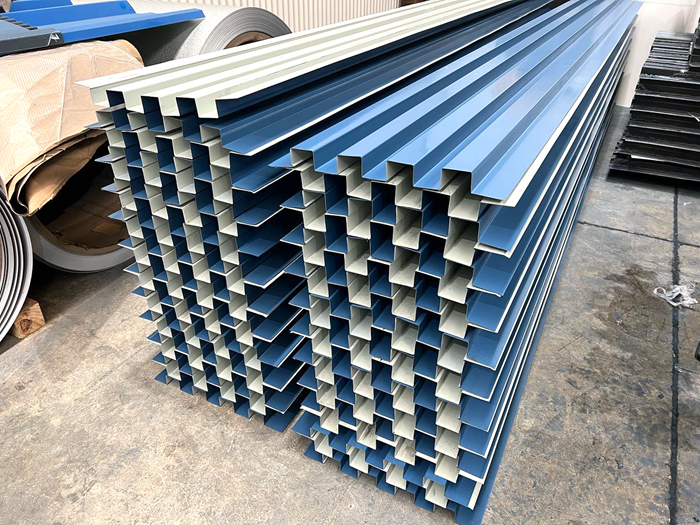

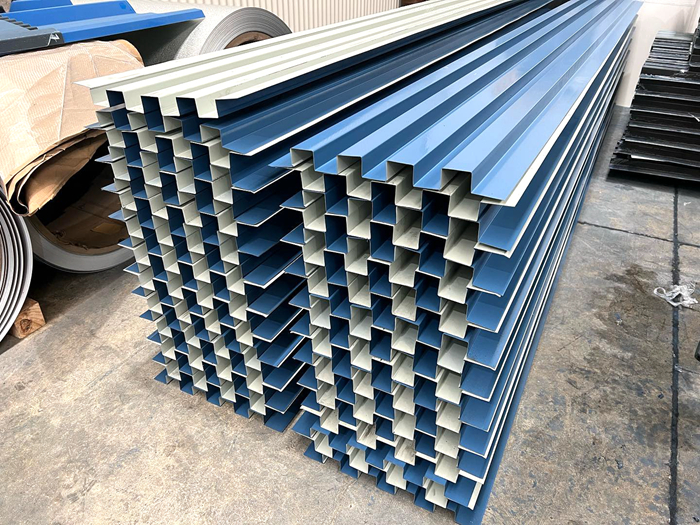

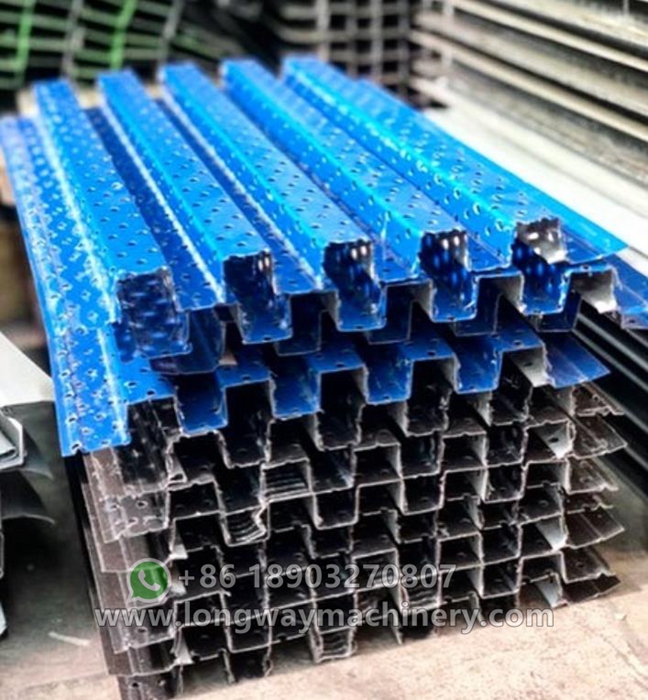

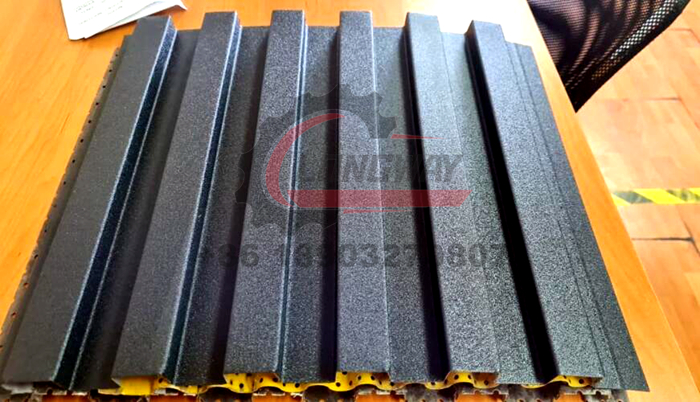

Below is the cladding wall sheets finished by our Quadro cladding roll forming machine, which received good feedback from our client . We can also design in different sizes according to your needs .

Wall Cladding Machine Advantages

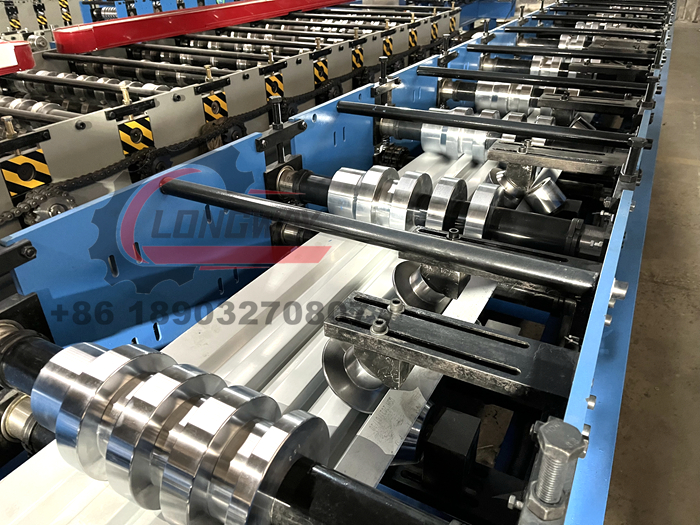

Roll Forming Process: Similar to a ceiling channel roll forming machine, a wall cladding machine utilizes a roll forming process to shape flat metal coils or sheets into the desired profile for wall cladding panels. The machine consists of multiple sets of rollers that gradually bend and form the metal to achieve the desired shape and dimensions.

Customization: The wall cladding machine can be adjusted to produce different profiles, sizes, and textures of wall cladding panels to suit the specific design preferences and requirements of construction projects. This customization capability allows for a wide range of architectural styles and design possibilities.

Efficiency and Precision: Modern cladding roll forming machines are equipped with advanced automation and computer-controlled systems, ensuring high efficiency, accuracy, and consistency in the manufacturing process. This results in uniform quality across the produced panels and helps meet tight production schedules.

Cost-Effectiveness: Wall cladding machines offer cost-effective solutions for producing large quantities of wall cladding panels compared to traditional manufacturing methods. The high-speed production capabilities and low per-unit costs make them suitable for mass production and large-scale construction projects.

Wall Cladding Machine Applications

Wall cladding panels produced by these wall cladding machines are used in various architectural and construction applications, both for exterior and interior walls. Common applications include: Wall cladding machine produced by roll forming machine supplier can provide exterior cladding for residential, commercial, and industrial buildings to enhance curb appeal, providing weather protection, and improving energy efficiency.

Interior wall cladding for decorative purposes, such as in lobbies, reception areas, retail spaces, and feature walls in homes, offices, hotels, and shopping malls.

Fire-rated cladding systems for compliance with building codes and regulations regarding fire safety.

Retrofitting existing buildings with new cladding to update their appearance, improve insulation, or address maintenance issues.

Technical Farameters

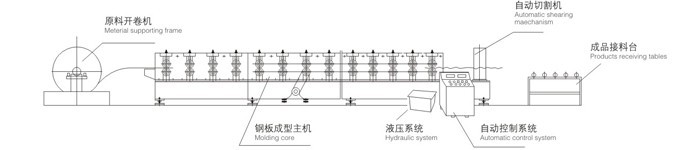

Working Process

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving table

|

Raw Material |

Coil Type |

PPGI,PPGL,GI |

|

Width |

600/610mm |

|

|

Thickness range |

29-22 Gauge (0.3-0.6mm) |

|

|

Power Requirement

|

Voltage |

380v/3ph/50hz(Customized) |

|

Main Motor power |

5.5+5.5kw |

|

|

Cutter power |

4kw |

|

|

Forming speed |

15-20m/min |

|

|

Machine Frame |

350mm H Beam Structure |

|

|

Thickness of structure |

18 mm Welded Steel Middle Support Plate |

|

|

Forming shaft |

75mm solid shaft with heat treatment |

|

|

Material Of Rollers |

High Grade 45# Forged Steel |

|

|

Forming stations |

22-26 rows Rolling Type: Separate rolling design concept, It can release Internal stress from the fheets, Then the sheet will be in good shape and high precision |

|

|

Transmission Way |

Chain drive 1 inch (Double Chain) |

|

|

Type of cutting |

Hydraulic Pillar type and length-set cutting |

|

|

Control system |

PLC Delta and Inverter Delta |

|

|

Screen |

Touch screen |

|

|

Dimension(Approx) |

11.5m×1.5m×1.2m |

|

|

Total weight (Approx) |

5.6T |

|

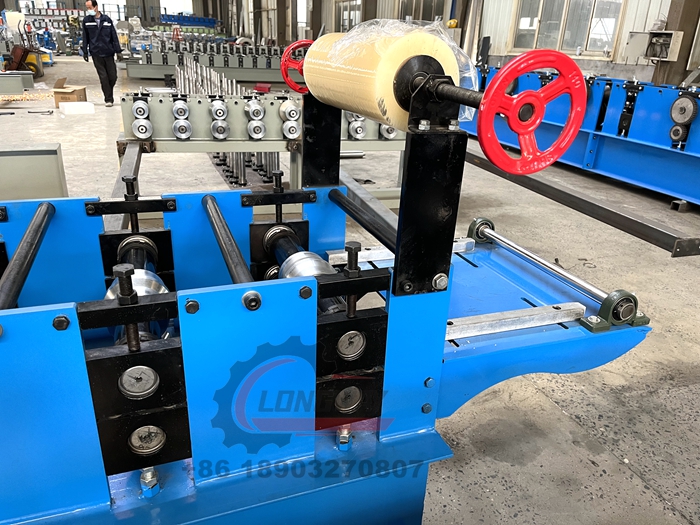

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

Revestimiento usado en fachadas, cortavistas y terminaciones. Está diseñado con un sistema de traslapo que permite su instalación tanto de manera horizontal con fijaciones a la vista.

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display