Product Details

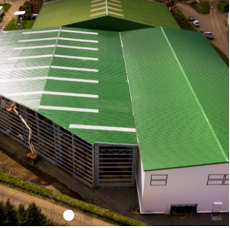

AG Panel Metal Roof, a low depth profile, economical panel solution for residential, commercial and agricultural roofing or post frame buildings.

AG panels are a very durable, high-value metal roofing system. Manufactured from 0.3-0.8mm thickness material.

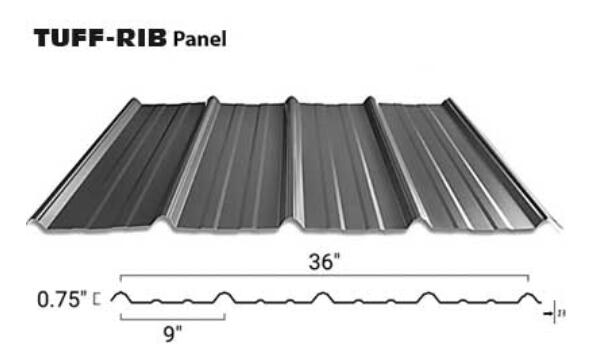

Tuff-Rib Panel is a light gauge throuh fastener roof tile and wall panel that is a great choice for commercial, industrial and agricultural.

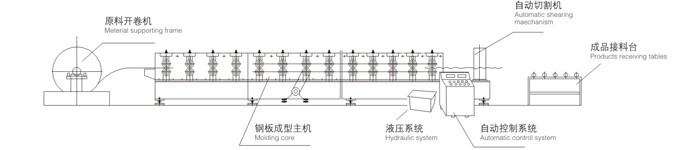

AG Panel Roll Former has following features:

- Fastener Design

- Standard and custom trim available

- Excellent for roof and siding

- Excellent for portable building.

AG Panels are low ribs. Longway Roll Forming Machine have a full range of AG Panel Roll Formers for different requirements of AG panles.

Technical Farameters

Working Process

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving table

|

US Ag classic rib roof panel roll forming machine

|

|

|

Raw Material

|

PPGI,PPGL

|

|

Material Thickness:24/26 Gauge (0.4-0.6 Mm)

|

|

|

Machine Frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|

Roller Material

|

45# steel, chromed on the surface

|

|

Forming Stations

|

Roller Stations :16-18 Rows

|

|

Diameter Of Shafts

|

Φ80mm Solid

|

|

Material Of Shafts

|

High Grade 45#,With Heat Treatment

|

|

Forming Speed

|

15 M/Min

|

|

Voltage

|

380v/50hz/3p (As Requested)

|

|

Transmission Way

|

By 1 Inch Chain (Double Chains)

|

|

Main Motor

|

5.5 KW

|

|

Cutting Blade Material

|

Gcr12 quenched treatment

|

|

Cutting Type

|

hydraulic post cutting

|

|

Driving Method

|

By pillar type Cylinder

|

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

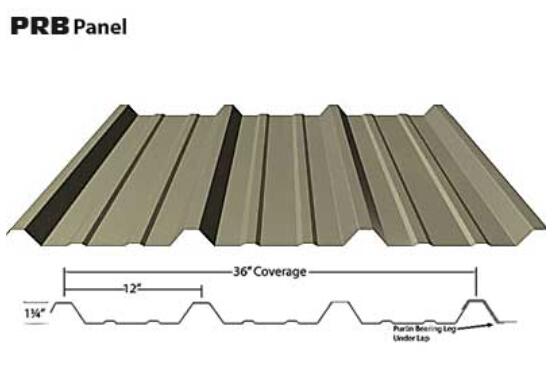

R Panel vs Ag Panel

Ag Panel is a slang term for one of the most popular exposed fastener metal roofing and siding profiles in the construction industry. Post-frame (aka pole barn) buildings and residential metal roofing represent the two largest construction segments for Ag Panel usage

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display