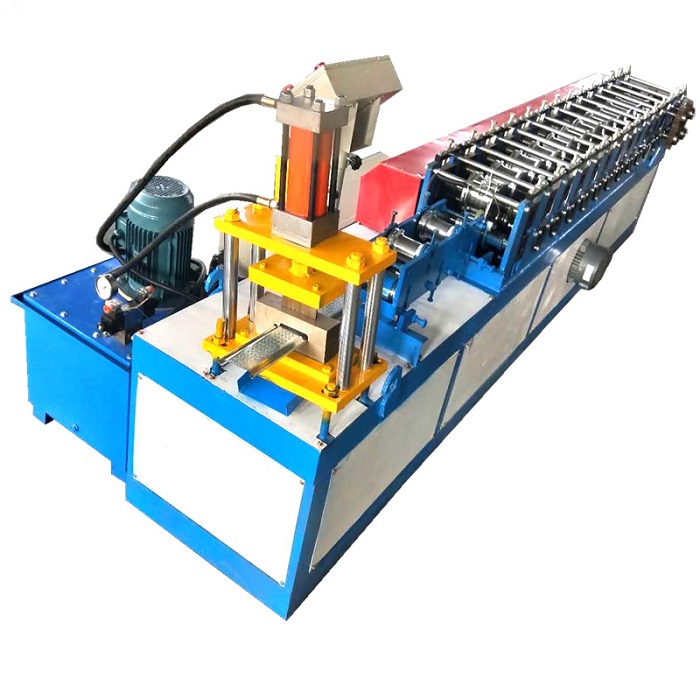

Roller Shutter Door Forming Machine

In the world of industrial manufacturing, the roller shutter door forming machine is a shining example of accuracy and efficiency. The production of roller shutter doors is streamlined by its automated operations, which have many benefits over conventional techniques. This machine converts raw metal coils into finely formed components that are tailored to exact requirements with minimal material waste, all at a speed and accuracy never seen before. It streamlines production operations by integrating feeding, shaping, and cutting processes smoothly, guaranteeing consistency and consistent quality in each door component. Furthermore, its computerized control system makes modification and alterations simple, enabling producers to easily satisfy a variety of project needs. The roller shutter door forming machine, with its unparalleled efficiency and versatility, is essentially the pinnacle of innovation and dependability, transforming the production environment.

Roller Shutter Door Forming Machine Faqs

What is a roller shutter door forming machine?

A roller shutter door forming machine is a specialized piece of equipment used in the manufacturing process of roller shutter doors. It employs a roll forming process to shape metal sheets into the components required for constructing roller shutter doors.

What materials can be used with a roller shutter door forming machine?

Roller shutter door forming machines are typically used with various metals, including steel, aluminum, and stainless steel. The choice of material depends on factors such as strength requirements, corrosion resistance, and aesthetic preferences.

What types of roller shutter doors can be produced with these machines?

Roller shutter door forming machines can produce a wide range of roller shutter door types, including manual and motorized doors, insulated and non-insulated doors, security doors, and fire-rated doors.

What are the advantages of using a roller shutter door forming machine?

The advantages of using a roller shutter door forming machine include increased efficiency, precision, and consistency in production. These machines streamline the manufacturing process, minimize material waste, and allow for customization to meet specific design requirements.

How does a roller shutter door forming machine work?

A roller shutter door forming machine works by feeding metal coils into the machine, which then pass through a series of roll forming stations. These stations gradually shape the metal into the desired profiles of the roller shutter door components. The formed components are then cut to the required lengths and assembled into complete roller shutter doors.

What are some common features of roller shutter door forming machines?

Common features of roller shutter door forming machines include decoilers or uncoilers for holding metal coils, feeding systems for continuous material supply, roll forming stations for shaping the metal, cutting mechanisms for precise cutting, and control systems for monitoring and adjusting machine parameters.

Are roller shutter door forming machines customizable?

Yes, roller shutter door forming machines can be customized to meet specific production requirements, such as different door sizes, profiles, and materials. Manufacturers can tailor the machine's features, such as roll forming stations, cutting mechanisms, and control systems, to accommodate various production needs.

What maintenance is required for roller shutter door forming machines?

Regular maintenance, including lubrication, inspection of components, and calibration of control systems, is essential to ensure the optimal performance and longevity of roller shutter door forming machines. Additionally, operators should follow safety protocols and guidelines to maintain a safe working environment.