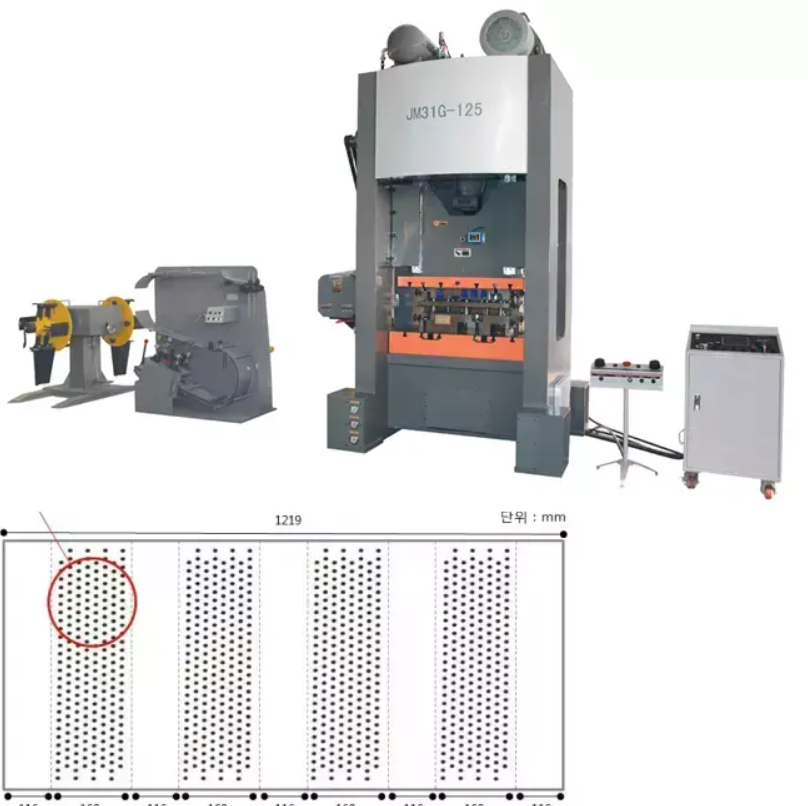

Cut to Length & Slitting Line

A versatile piece of industrial equipment, the cut-to-length and slitting machine is made to precisely cut and slit a variety of materials into precise lengths or widths, including copper, aluminum, and steel coils. Because of its many uses, it is a vital instrument in a wide range of production processes, such as those in the packaging, construction, automotive, and metal fabrication industries. This machine offers unmatched efficiency and accuracy because to its high-precision cutting mechanisms and sophisticated automation, guaranteeing consistent results throughout big production volumes. When it comes to maximizing material use and reducing waste, the cut-to-length and slitting machine is an excellent tool for producing custom-sized sheets, strips, or coils. Its configurable controls and user-friendly interface provide quick setup and smooth operation for various cutting needs, increasing output and decreasing downtime. This machine is an essential tool in contemporary production facilities because it can perform a wide range of tasks, from precise length cutting to high-speed slitting, enabling businesses to satisfy exacting quality requirements and easily react to changing market needs.

Difference Between Slitting Machine and Cut To Length Line

The primary difference between a slitting machine and a cut-to-length (CTL) line lies in their respective functions and the types of materials they process:

Slitting Machine:

Function: A slitting machine is designed to cut wide coils of material into narrower strips. It essentially slices the material longitudinally, creating multiple narrower coils or strips from a single wider coil.

Materials: Slitting machines are commonly used for processing materials such as steel, aluminum, copper, and other metals, as well as various types of flexible materials like paper, plastic, and textiles.

Applications: Slitting machines are widely used in industries such as metal processing, automotive, packaging, and textiles, where precise width requirements or multiple narrow coils are needed.

Cut-to-Length (CTL) Line:

Function: A CTL line is specifically designed to cut flat sheets or coils of material into individual pieces of predetermined lengths. It cuts across the width of the material rather than longitudinally.

Materials: CTL lines are typically used for processing materials like steel, aluminum, stainless steel, and other metals, as well as non-metal materials such as plastic sheets and composite materials.

Applications: CTL lines are commonly used in industries such as metal fabrication, construction, appliance manufacturing, and aerospace, where accurately sized pieces or sheets are required for further processing or assembly.

Cut to Length and Slitting Machine Advantages

Cut-to-length (CTL) lines and slitting machines offer several advantages in industrial manufacturing processes:

Advantages of Cut-to-Length (CTL) Lines:

Precision Cutting: CTL lines provide accurate and consistent cutting of materials into individual pieces of predetermined lengths, ensuring uniformity in the final product.

Customization: They offer flexibility in cutting various materials to specific lengths, meeting diverse customer requirements and project specifications.

High Productivity: CTL lines are capable of high-speed operation, enabling efficient production and quick turnaround times for large volumes of cut-to-length material.

Minimized Material Waste: By precisely cutting materials to required lengths, CTL lines help minimize material waste, optimizing material utilization and reducing production costs.

Automation: Modern CTL lines are often equipped with advanced automation features, such as programmable controls and integrated quality inspection systems, enhancing productivity and quality assurance.

Advantages of Slitting Machines:

Versatility: Slitting machines are highly versatile and can process a wide range of materials, including metals, plastics, paper, and textiles, into narrower strips or coils.

Material Savings: By converting wide coils into narrower strips, slitting machines help optimize material usage and reduce waste, resulting in cost savings for manufacturers.

Customizable Widths: They allow for precise customization of strip widths, accommodating varying customer requirements and application needs.

High Throughput: Slitting machines are capable of high-speed operation, enabling rapid processing of large coils into multiple narrower strips, thereby enhancing production efficiency.

Quality Control: Advanced slitting machines often feature integrated quality control systems that monitor the slitting process in real-time, ensuring consistent strip widths and minimizing defects.