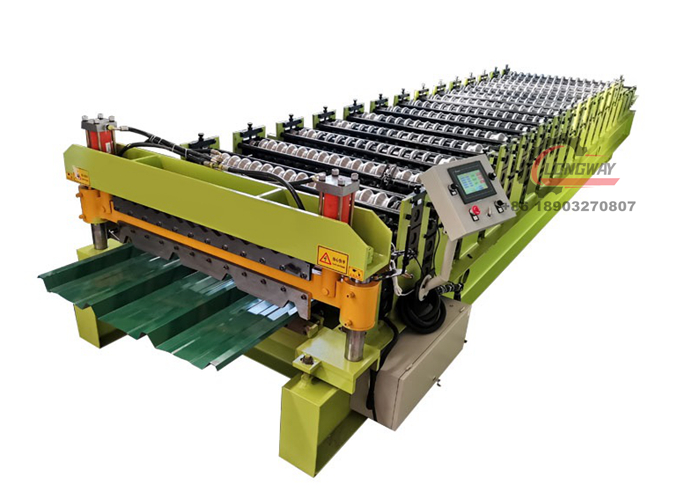

Double Layer Roll Forming Machine

A double layer roll forming machine presents a host of advantages that revolutionize the production of metal roof panels. This innovative technology combines the capabilities of two roll forming stations within a single machine, offering unparalleled efficiency and flexibility. With dual-layer functionality, manufacturers can simultaneously produce two different profiles or thicknesses of metal panels, doubling output capacity and streamlining production processes. This not only accelerates manufacturing speed but also optimizes resource utilization, reducing both time and material waste. The versatility of a double layer roll forming machine allows for greater customization options, catering to diverse project requirements with ease. By integrating advanced automation and precision engineering, these machines deliver consistent quality while minimizing labor costs and enhancing overall productivity. Additionally, their compact design saves valuable floor space, making them ideal for both small-scale workshops and large industrial facilities.

What Is Double Layer Roll Forming Machine

A double layer roll forming machine is a specialized piece of equipment used in the manufacturing of metal roofing and wall cladding panels. Unlike a traditional single-layer roll forming machine, which produces one type of panel at a time, a double layer roll forming machine has the capability to produce two different types of panels simultaneously.

The machine typically consists of two sets of roll forming stations stacked vertically, with each set dedicated to forming a specific profile or shape of panel. This configuration allows for increased production efficiency and versatility, as manufacturers can produce different types of panels without the need to stop and reconfigure the machine.

Double layer roll forming machines are commonly used in the construction industry for producing metal roofing panels with varying profiles, thicknesses, and surface finishes. They offer benefits such as increased productivity, reduced setup time, and greater flexibility in meeting diverse customer demands.

Overall, double layer roll forming machines play a crucial role in streamlining the manufacturing process of metal roofing and wall cladding systems, allowing manufacturers to produce high-quality panels efficiently and cost-effectively.