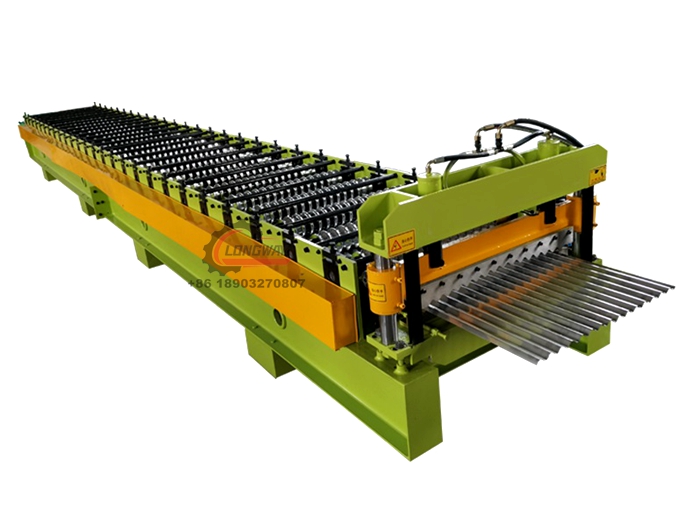

Corrugated Roofing Sheet Machine

A corrugated roofing sheet machine is a priceless tool in the building industry because of its many benefits. This specialized equipment produces corrugated sheets with remarkable accuracy and efficiency by streamlining the manufacturing process. Automating the corrugated roofing panel production process reduces wasteful material use and maximizes resource efficiency. These devices guarantee consistent quality and dimensional correctness. They also increase productivity by cutting manufacturing times dramatically when compared to conventional processes, which makes it easier for manufacturers to meet deadlines for large-scale orders and projects. Additionally, corrugated roofing sheet machines are versatile in their design, enabling customisation in accordance with particular project requirements, including varying profiles, thicknesses, and lengths, thereby meeting a variety of structural requirements and architectural styles.

Corrugated Roofing Sheet Machine Features

Roll Forming System: At the heart of the machine, the roll forming system utilizes a series of rollers to shape flat metal coils into corrugated profiles. This system ensures precision in forming corrugations, maintaining uniformity and consistency across the length of the sheet.

Material Handling Mechanism: Equipped with a decompiler, feeder, and cutter, the machine efficiently handles metal coils, feeds them into the roll-forming system, and cuts the formed sheets to the desired length. Advanced material handling mechanisms minimize downtime and optimize production throughput.

Automated Control System: Modern corrugated roofing sheet machines are equipped with advanced control systems that automate the entire manufacturing process. Operators can set parameters such as sheet dimensions, corrugation profiles, and production speed, ensuring accuracy and repeatability in production.

Quick Changeover Capabilities: Some machines feature quick-change tooling systems, allowing for rapid adjustments between different corrugation profiles or sheet dimensions. This feature enhances flexibility and enables manufacturers to respond swiftly to changing market demands.

High-Speed Production: Corrugated roofing sheet machines are designed for high-speed production, enabling manufacturers to meet tight project deadlines and fulfill large orders efficiently. High production speeds maximize output while minimizing per-unit manufacturing costs.

Durability and Reliability: Built with robust materials and precision engineering, these machines are designed for long-term durability and reliability. They withstand the rigors of continuous operation in demanding manufacturing environments, minimizing downtime and maintenance requirements.

Safety Features: Safety is paramount in industrial machinery, and corrugated roofing sheet machines are equipped with safety features such as emergency stop buttons, safety guards, and interlocking systems to protect operators and prevent accidents.

Modular Design: Many machines feature a modular design, allowing for easy expansion or customization to accommodate future production needs. Manufacturers can add additional units or upgrade components to enhance functionality and capacity as required.