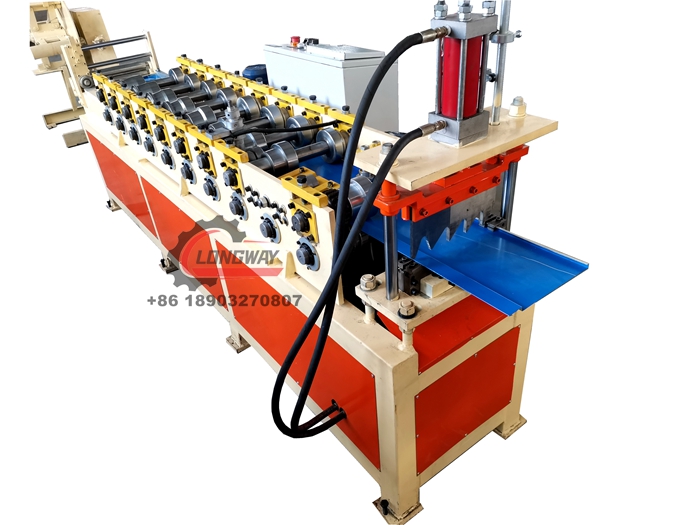

Roof and Wall Panel Machine

Purchasing a roof panel machine provides numerous benefits to both construction and industrial enterprises. A roof panel machine's sophisticated engineering and cutting-edge technologies optimize the production process, making it possible to produce high-quality roofing panels quickly and affordably. Businesses can greatly enhance their production capacity while lowering labor expenses and material waste by automating the construction of roof panels. These devices also guarantee uniform panel profiles and dimensions, which improves product quality and increases customer satisfaction. A roof panel machine enables enterprises to easily and efficiently meet the growing need for long-lasting and visually beautiful roofing solutions, whether they are for commercial or residential applications.

What Is Roll Forming Machine Used For?

A roll forming machine is a versatile industrial equipment used in various manufacturing processes across different industries. Its primary function is to transform flat metal sheets or coils into desired shapes and profiles through a continuous bending process. These machines utilize a series of rollers positioned along a linear path, each set to gradually bend the metal into the desired shape. The metal strip passes through multiple forming stations, where each set of rollers incrementally shapes the material until it reaches the final profile. Roll forming machines are used to produce a wide range of products, including but not limited to roofing panels, wall cladding, steel framing components, automotive parts, structural sections, and consumer goods such as shelving and furniture. The versatility of roll forming machines allows manufacturers to create complex and customized profiles with high precision and efficiency. Additionally, roll forming offers advantages such as material savings, consistent quality, and the ability to process various metals including steel, aluminum, copper, and stainless steel, making it a preferred method for mass production in industries worldwide.

Roof Panel Machine FAQ

What is a roof panel machine?

A roof panel machine is a piece of industrial equipment used to manufacture roofing panels from raw materials such as metal coils. It utilizes a series of rollers and forming stations to shape the metal into the desired profile of the roofing panel.

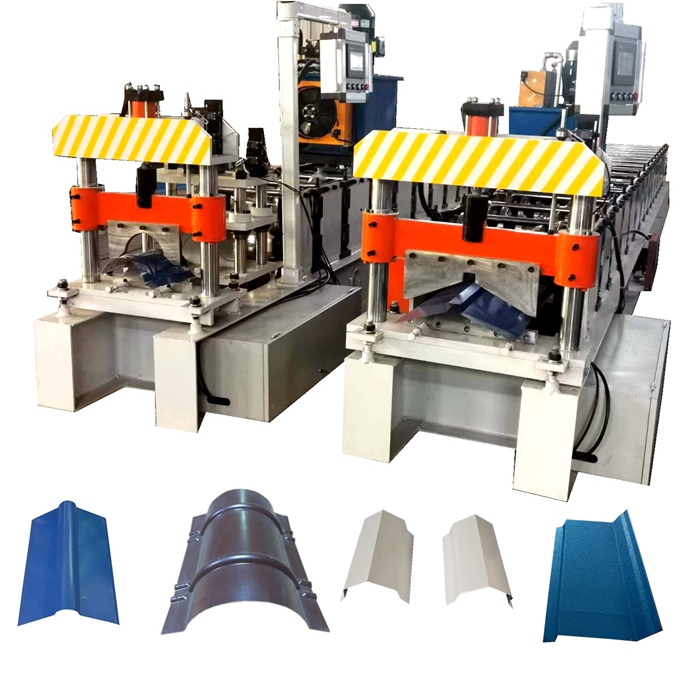

What types of roofing panels can be produced with a roof panel machine?

Roof panel machines can produce a variety of roofing panels, including corrugated panels, standing seam panels, R-panel, and custom-designed profiles tailored to specific project requirements.

What are the advantages of using a roof panel machine?

Some advantages include increased production efficiency, precise and consistent panel manufacturing, reduced labor costs, minimized material waste, and the ability to produce customized panels for diverse roofing applications.

What materials can be used with roof panel machines?

Roof panel machines are primarily designed to process metal coils, including galvanized steel, aluminum, copper, and stainless steel. Some machines may also be capable of processing other materials such as composite panels or coated sheets.

Can roof panel machines be customized for specific panel profiles?

Yes, many manufacturers offer customization options to tailor roof panel machines to produce specific panel profiles according to customer requirements, including dimensions, rib patterns, and panel thickness.

What are common applications for roofing panels produced by roof panel machines?

Roofing panels manufactured by roof panel machines are commonly used in residential, commercial, and industrial construction projects for roofing applications such as roofs for houses, warehouses, factories, agricultural buildings, and commercial structures.

How can I maintain a roof panel machine?

Regular maintenance is essential to ensure optimal performance and longevity of the machine. Maintenance tasks may include lubricating moving parts, inspecting and replacing worn components, and cleaning the machine regularly.

What safety precautions should be followed when operating a roof panel machine?

Operators should receive proper training on machine operation and safety procedures. Safety measures may include using protective equipment, ensuring proper machine guarding, and following lockout/tagout procedures during maintenance.

Where can I purchase a roof panel machine?

Roof panel machines are available from various manufacturers and roofing sheet making machine suppliers worldwide. It's essential to research and choose a reputable supplier that offers quality equipment, reliable customer support, and after-sales service. Welcome to contact Cangzhou Longway International Trade Co., Ltd.