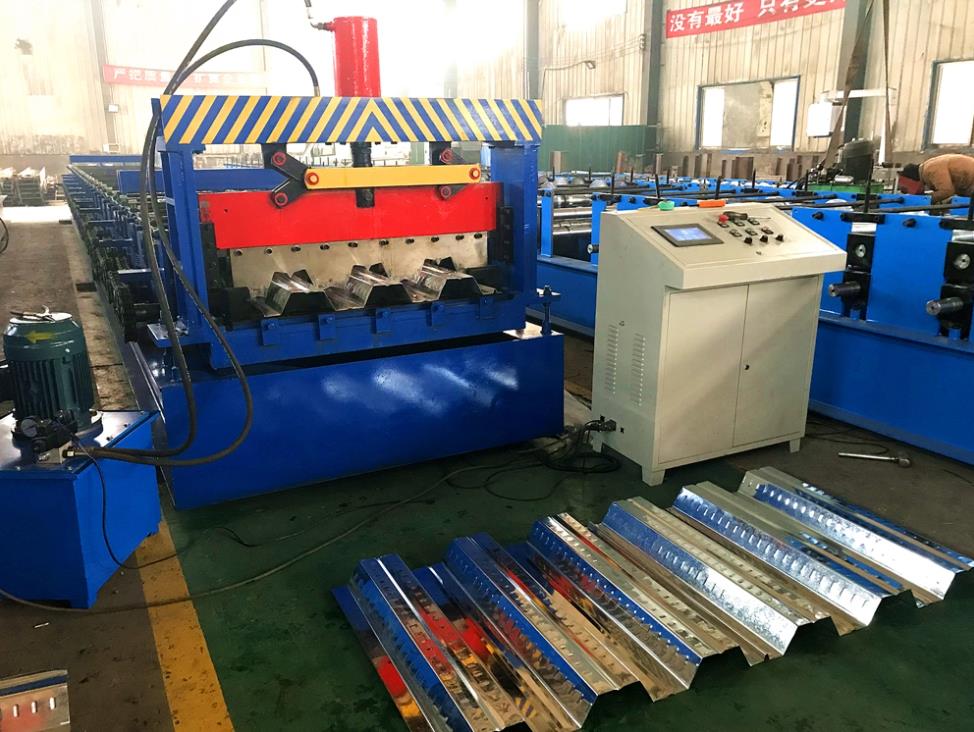

Floor Deck Roll Forming Machine

A floor deck roll forming machine is a specialized piece of equipment used in the construction industry to manufacture floor decking panels, also known as steel deck or metal decking. These panels are commonly used in composite floor systems for multi-story buildings, providing structural support and a surface for concrete to be poured on top.

Here's an overview of how a floor deck roll forming machine typically operates and its key components:

Material Feeding: The process begins with feeding a coil of steel sheet into the machine. The steel coil is typically made of galvanized steel or other durable materials suitable for structural applications.

Roll Forming: The steel sheet passes through a series of rollers and forming stations within the machine. These rollers gradually shape the flat steel sheet into the desired profile for the floor decking panel. The profile typically includes features such as ribs, embossments, and interlocking edges, which enhance structural strength and provide bonding with concrete.

Cutting and Length Measurement: Once the desired profile is formed, the machine includes a cutting mechanism to cut the formed steel sheet into individual floor decking panels. A length measurement system ensures that each panel is cut to the specified length.

Stacking or Packaging: After cutting, the finished floor decking panels may be stacked or packaged for transportation to the construction site or storage facility. Some machines may include automatic stacking or packaging systems for efficiency.

Floor Deck Roll Forming Machine FAQs

What is a floor deck roll forming machine?

A floor deck roll forming machine is a specialized piece of equipment used in the construction industry to manufacture floor decking panels, which are integral components of composite floor systems in multi-story buildings.

What are floor decking panels used for?

Floor decking panels, also known as steel deck or metal decking, provide structural support and a surface for concrete to be poured on top. They are commonly used in commercial, industrial, and residential buildings to create composite floor systems.

What materials can be used with a floor deck roll forming machine?

Floor deck roll forming machines typically process coils of galvanized steel or other durable materials suitable for structural applications.

What types of profiles can be produced by a floor deck roll forming machine?

These machines can produce various profiles and configurations of floor decking panels, including different rib patterns, interlocking edges, and embossments, to meet the specific requirements of construction projects.

What are the advantages of using floor deck roll forming machines?

Floor deck roll forming machines offer several advantages, including high-speed production, precision control over panel dimensions, versatility in profile design, and durability for long-term use in industrial environments.

Are floor deck roll forming machines customizable?

Yes, many floor deck roll forming machines can be customized to produce different panel widths, thicknesses, rib patterns, and lengths, allowing manufacturers to tailor production to meet specific project needs.

What safety features should be considered when operating a floor deck roll forming machine?

Safety features such as guards, emergency stop mechanisms, and safety interlocks are essential to ensure the safety of operators working with the machine. Proper training and adherence to safety protocols are also critical.

How do floor deck roll forming machines contribute to construction efficiency?

By automating the manufacturing process of floor decking panels, these machines help reduce labor costs, minimize material waste, and increase production efficiency, ultimately contributing to faster and more cost-effective construction of buildings.