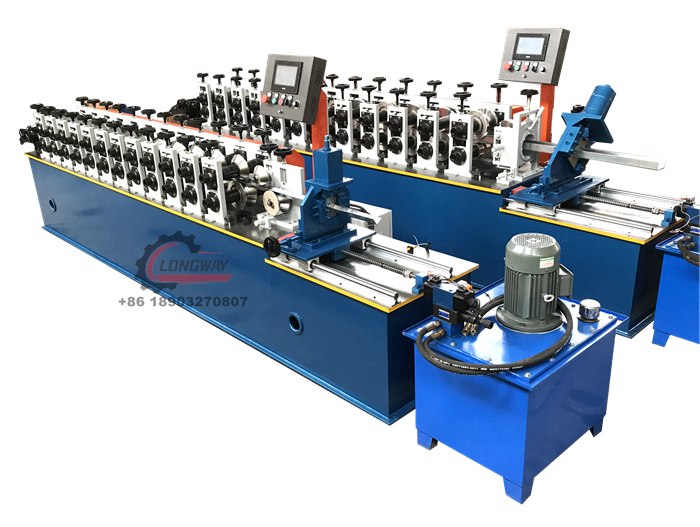

Drywall Profiles Roll Former

A drywall profile machine is a specialized piece of equipment designed for the efficient production of metal profiles used in drywall construction. This machine automates the process of forming metal studs, tracks, and other components essential for framing interior walls and ceilings with drywall panels. By precisely shaping and cutting metal coils according to predefined specifications, the drywall profile machine ensures consistency and accuracy in the production of these components, enabling faster and more cost-effective construction processes.

How Does a Drywall Profile Machine Work?

A drywall profile machine works by automating the process of forming metal studs, tracks, and other components used in drywall construction. The process begins with feeding metal coils into the machine, where they are gradually shaped and cut to the desired dimensions using a series of rollers, dies, and cutting mechanisms. These components are typically made of galvanized steel or other durable materials to ensure strength and longevity in the finished product. The machine operates with precision, accurately forming each component according to predefined specifications, such as width, thickness, and profile shape. Once formed, the metal components are automatically discharged from the machine, ready for further processing or assembly in the construction of interior walls and ceilings. Overall, the drywall profile machine streamlines the manufacturing process, increasing efficiency and productivity in drywall construction projects.

Benefits of using a Drywall Profile Machine

Using a drywall profile machine offers several benefits in the construction industry. Firstly, it enhances efficiency by automating the process of forming metal studs, tracks, and other components used in drywall construction. This automation reduces labor requirements and speeds up production, leading to faster project completion times and cost savings. Additionally, the precision and consistency of the machine ensure uniformity in the dimensions and quality of the produced components, resulting in smoother and more accurate installations. Moreover, drywall profile machines enable customization, allowing for the creation of various profiles and sizes to meet specific project requirements. This versatility enhances flexibility in design and construction, accommodating diverse architectural styles and structural needs. Furthermore, using a drywall profile machine promotes sustainability by minimizing material waste and optimizing resource utilization. Overall, the use of a drywall profile machine improves productivity, quality, customization options, and sustainability in drywall construction projects.

Potential Applications of Drywall Profile Machines

Drywall profile machines have numerous potential applications across various sectors of the construction industry. Firstly, in residential construction, these machines are used to fabricate metal studs and tracks for framing interior walls and ceilings. The precise forming capabilities of drywall profile machines ensure uniformity and accuracy in dimensions, resulting in sturdy and reliable structural frameworks for homes.

In commercial construction, drywall profile machines play a crucial role in constructing office spaces, retail outlets, and other commercial buildings. By producing metal studs, tracks, and other framing components efficiently, these machines contribute to faster construction timelines and cost-effective project execution.

Moreover, drywall profile machines find applications in industrial construction projects, such as warehouses, factories, and manufacturing facilities. They are used to fabricate robust metal frames and support structures for partition walls, machinery enclosures, and storage areas, providing durability and stability in industrial environments.

Additionally, drywall profile machines can be utilized in renovation and remodeling projects to replace or upgrade existing interior walls and ceilings. Their ability to produce custom profiles and sizes allows contractors to adapt to specific project requirements and architectural designs.

Furthermore, drywall profile machines have applications beyond traditional construction sectors. For example, they can be used in temporary structures, such as event spaces, exhibition booths, and modular buildings, where quick assembly and disassembly are essential.

Overall, the potential applications of drywall profile machines span various construction sectors, including residential, commercial, industrial, renovation, and temporary structures, offering versatility, efficiency, and cost-effectiveness in the fabrication of metal framing components for drywall construction.