Door Frame Forming Machine

A door frame forming machine offers a myriad of advantages, revolutionizing the manufacturing process of door frames with unparalleled efficiency and precision. By automating the production of door frames, this specialized equipment streamlines workflows, reduces labor costs, and enhances productivity in manufacturing operations. With customizable settings and precise control mechanisms, it ensures consistent quality and accuracy in the fabrication of door frames, meeting stringent industry standards and customer specifications effortlessly. Moreover, the machine optimizes material utilization, minimizing waste and maximizing yield, thereby contributing to cost savings and sustainability efforts. Its versatility allows for the production of various door frame designs and profiles, catering to diverse customer needs and architectural requirements. Overall, the door frame forming machine stands as a cornerstone of innovation in the door manufacturing industry, empowering manufacturers to achieve higher levels of efficiency, quality, and competitiveness in the market.

Introduction to Door Frame Making Machines

Door frame making machines are integral to the manufacturing process of door frames, playing a crucial role in producing components that form the structural framework of doors. These machines are designed to efficiently and precisely fabricate door frame components from raw materials such as metal or wood, ensuring quality, consistency, and customization according to specific requirements.

At their core, door frame making machines employ various techniques and processes to shape raw materials into the desired profiles, dimensions, and configurations needed for door frames. They encompass a wide range of machinery types, each tailored to specific materials, production volumes, and customization options.

Key components of door frame making machines typically include:

Feeding System: Door frame making machines often feature a feeding mechanism that delivers raw materials, such as metal coils or wooden boards, into the machine for processing. This ensures a continuous supply of material throughout the fabrication process.

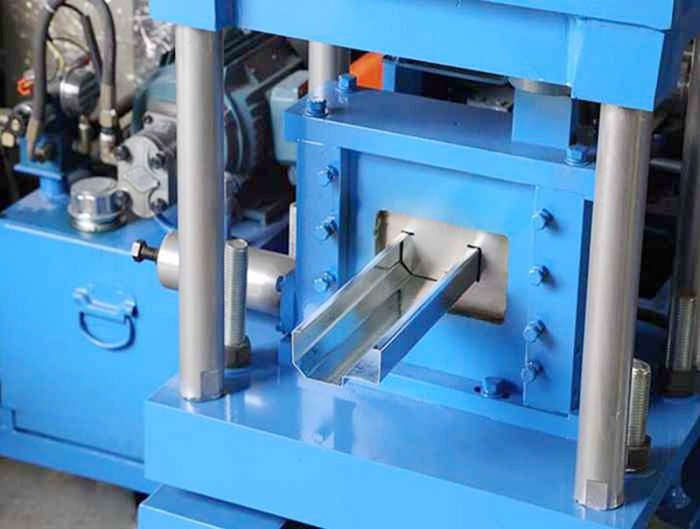

Shaping and Forming Units: These units utilize different methods such as roll forming, bending, pressing, cutting, or milling to shape raw materials into the required profiles and dimensions of door frame components. Roll forming machines, for instance, use a series of rollers to gradually form metal coils into specific shapes, while hydraulic press machines exert pressure to bend or punch materials into shape.

Joining and Assembly Stations: Some door frame-making machines incorporate assembly stations where individual components are joined, welded, riveted, or fastened together to form complete door frames. These stations ensure the structural integrity and stability of the finished frames.

Cutting and Sawing Equipment: Cutting and sawing machines are utilized to precisely cut raw materials to the required lengths, angles, and dimensions needed for door frame assembly. They may employ various cutting methods such as sawing, shearing, or milling.

Control and Automation Systems: Modern door frame making machines are often equipped with advanced control systems, including programmable logic controllers (PLCs) and human-machine interfaces (HMIs). These systems enable operators to monitor and control the fabrication process, adjust parameters, and ensure consistent quality and accuracy.

Door frame making machines offer numerous advantages, including increased efficiency, reduced labor costs, improved productivity, and the ability to produce customized door frames tailored to specific design requirements. By automating and streamlining the manufacturing process, these machines play a pivotal role in meeting the demand for high-quality door frames in various industries, including construction, architecture, and interior design.