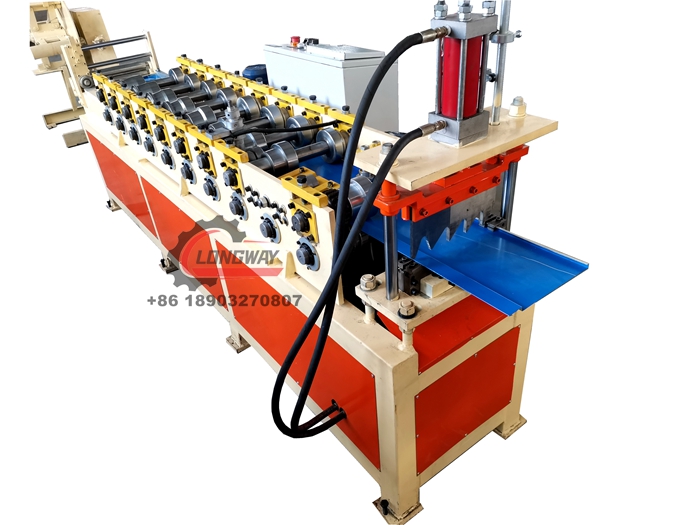

Standing Seam Roof Panel Machine

A standing seam roof panel machine is a specialized piece of equipment designed to fabricate standing seam roof panels with precision and efficiency. This machine automates the process of roll forming, allowing for the seamless creation of roof panels characterized by their distinct standing seams, which interlock to provide exceptional weather resistance and aesthetic appeal. Standing seam roof panel machines utilize advanced technology to produce panels of consistent quality, ensuring uniformity in dimensions, profiles, and seam integrity. By streamlining production and minimizing material wastage, these machines enable manufacturers and contractors to meet project deadlines effectively while maintaining high standards of craftsmanship.

6 Reasons You Should Buy a Standing Seam Metal Roof Panel Machine

Investing in a standing seam metal roof panel machine offers numerous benefits that can significantly enhance your business operations and bottom line. Here are six compelling reasons why purchasing such a machine is a wise decision:

Increased Efficiency: With a standing seam metal roof panel machine, you can streamline your production process, significantly reducing the time and labor required to fabricate roof panels. The automated roll forming capabilities enable fast and precise manufacturing, allowing you to meet tight project deadlines and increase overall productivity.

Cost Savings: By producing your own standing seam metal roof panels in-house, you can eliminate the need to outsource fabrication to third-party suppliers. This results in substantial cost savings over time, as you no longer have to pay markups or additional fees associated with outsourcing. Additionally, the reduced labor requirements and minimal material wastage contribute to further cost efficiencies.

Customization Options: Owning a standing seam metal roof panel machine grants you the flexibility to customize panels according to your clients' specific requirements. Whether it's altering dimensions, profiles, or seam designs, you have the freedom to accommodate diverse architectural styles and project needs, enhancing customer satisfaction and expanding your market reach.

Quality Control: With direct control over the manufacturing process, you can uphold strict quality standards and ensure consistency in panel dimensions, thickness, and seam integrity. This helps maintain the reputation of your brand by delivering high-quality, durable roof panels that meet industry standards and exceed customer expectations.

Versatility and Adaptability: Standing seam metal roof panel machines are versatile tools that can accommodate various types of metal materials, including steel, aluminum, and copper. This versatility allows you to diversify your product offerings and cater to different market segments, thereby maximizing your business opportunities and revenue potential.

Long-Term Investment: Investing in a standing seam metal roof panel machine is a strategic long-term investment that can yield substantial returns over its operational lifespan. As the demand for metal roofing continues to grow, owning your fabrication equipment positions your business for sustainable growth and profitability in the years to come.