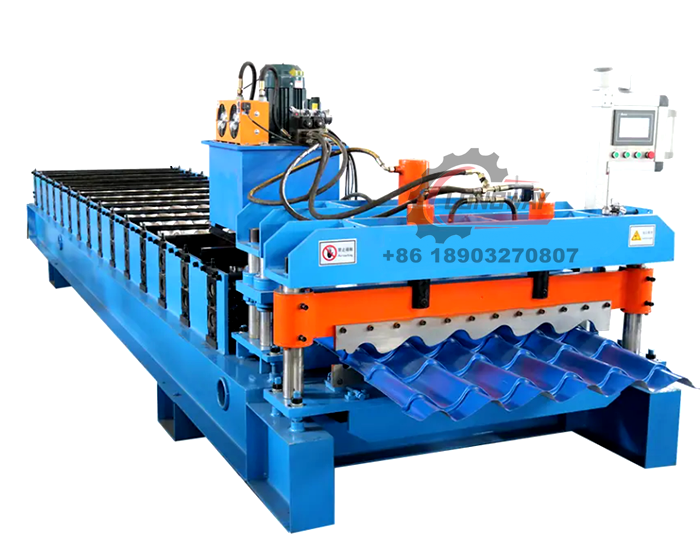

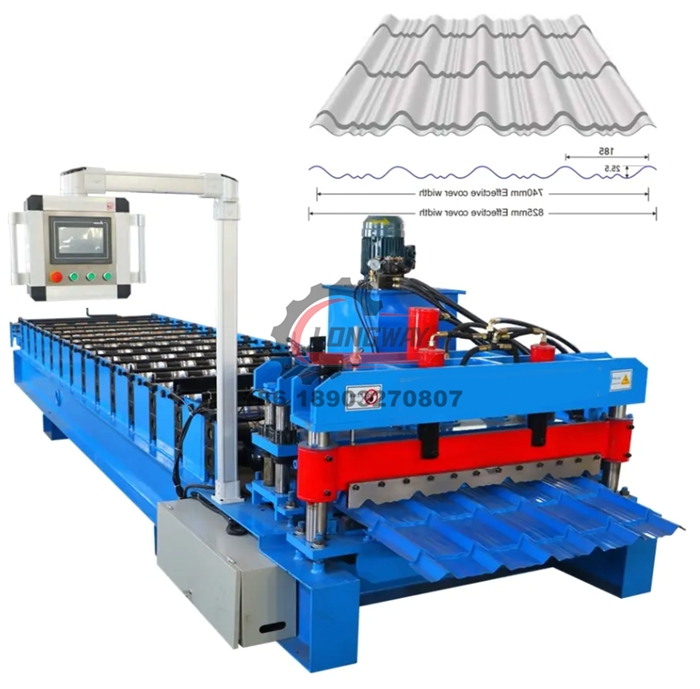

Glazed Roof Tile Forming Machine

The glazed sheet roll forming machine presents a transformative solution in the construction industry, offering a myriad of advantages that revolutionize the production of glazed sheets. Primarily, these machines excel in precision and consistency, ensuring that each sheet is fabricated with impeccable accuracy in dimensions, thickness, and profile. This precision not only enhances the aesthetic appeal of the glazed sheets but also optimizes material usage, minimizing waste and maximizing resource efficiency. Moreover, the automated nature of these machines significantly boosts productivity, enabling swift and continuous fabrication of glazed sheets to meet demanding project schedules. This heightened efficiency translates into cost savings and increased competitiveness for manufacturers and contractors alike. Additionally, glazed sheet roll forming machines empower customization, allowing for the creation of a diverse range of designs and configurations to suit various architectural styles and project requirements. With their ability to deliver superior quality, efficiency, and flexibility, these machines stand as indispensable assets in modern construction endeavors.

Glazed Tile Roll Forming Machine Benefits

The glazed tile roll-forming machine offers a host of benefits that make it an invaluable asset in the construction industry. Firstly, it ensures precision and consistency in the production of glazed tiles, resulting in uniform dimensions, thickness, and profiles. This precision enhances the aesthetic appeal of the tiles while also optimizing material usage, minimizing waste, and maximizing resource efficiency.

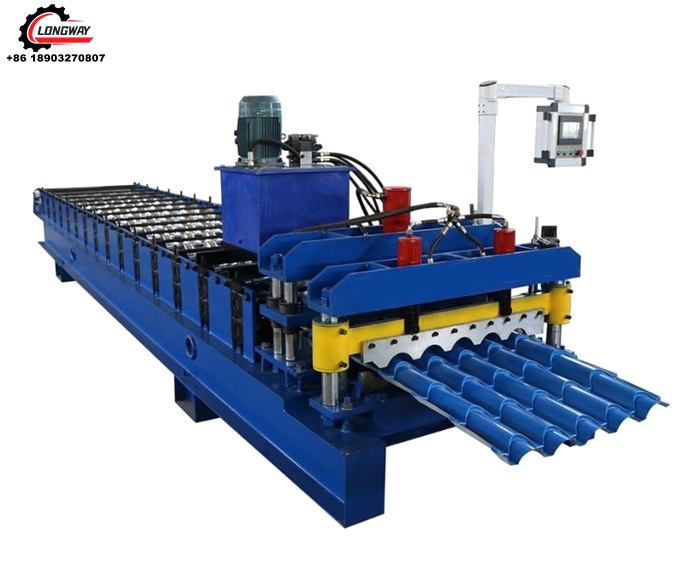

Secondly, the automated operation of the machine significantly enhances productivity, enabling the swift and continuous fabrication of glazed tiles. This increased efficiency allows manufacturers and contractors to meet tight project deadlines while also reducing labor costs and improving overall profitability.

Furthermore, the glazed tile roll-forming machine facilitates versatility in design, allowing for the creation of a wide range of tile shapes, sizes, and configurations to suit diverse architectural styles and project requirements. Whether it's traditional or contemporary designs, these machines can accommodate various customization needs, providing flexibility and creative freedom to designers and builders.

Additionally, glazed tiles produced by these machines offer exceptional durability and longevity, thanks to their resistance to corrosion, weathering, and structural degradation. This durability ensures that the tiles maintain their aesthetic appeal and structural integrity over time, reducing the need for frequent maintenance and replacement.