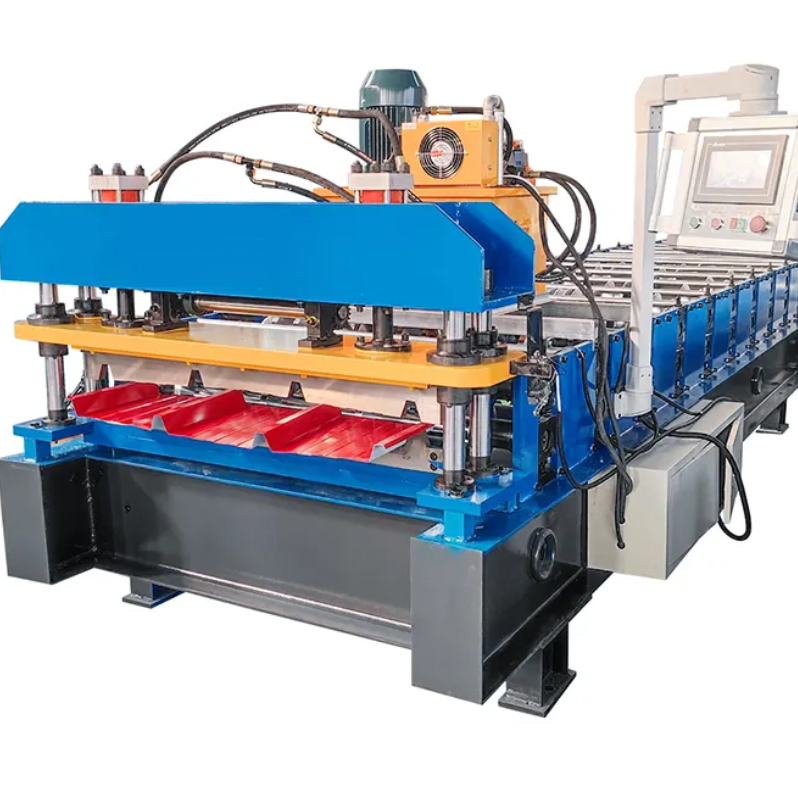

Metal Roof Panel Machine

With so many benefits that metal roof rolling machines provide, they are an essential tool for manufacturers and roofing contractors alike, revolutionizing the roofing business. These cutting-edge devices expedite the manufacturing process and provide unmatched accuracy, versatility, and efficiency. They save production time and costs by a great deal by automating labor-intensive manual procedures when fabricating metal roofing panels on-site or in manufacturing facilities. Further, users may easily accommodate different architectural styles, sizes, and profiles with metal roof rolling machines, which enable users to customize roofing panels to exact requirements. Long-lasting and highly effective roofing solutions are the outcome of their sturdy structure and cutting-edge technology, which guarantee consistent quality and longevity. Metal roof rolling machines, which provide unparalleled speed and suitability for both commercial and residential roofing applications, raise the bar for roofing quality.

Metal Roof Panel Roll Forming Machine Advantages

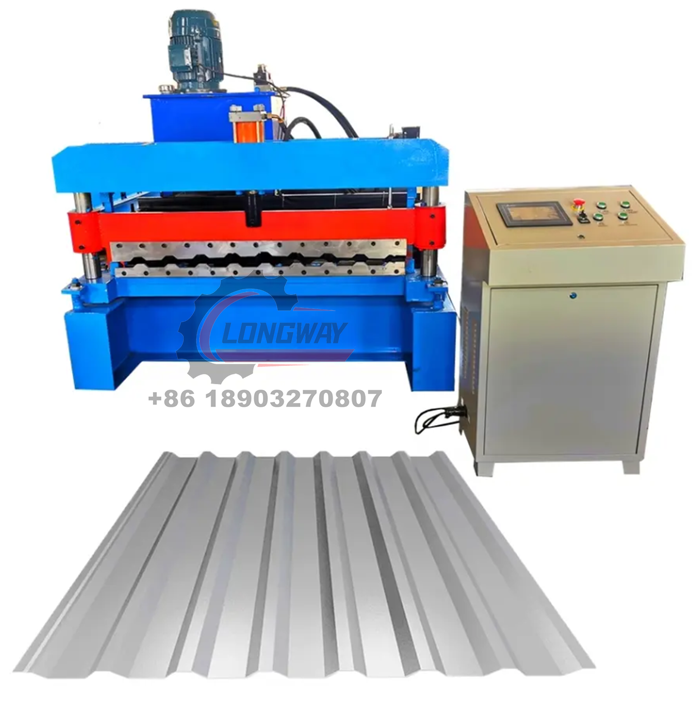

Metal roof panel roll forming machines are highly valuable in the construction sector due to their numerous benefits. Primarily, they facilitate the effective manufacturing of precision and consistently high-quality metal roofing panels. The automated procedure guarantees consistency in thickness, profiles, and dimensions, reducing wasteful material use and maximizing resource efficiency.

By drastically cutting production time when compared to conventional methods, these devices also increase productivity. They can quickly create large quantities of panels using high-speed roll forming capabilities, fulfilling project deadlines and improving overall efficiency.

Roll-forming machines for metal roof panels also enable design adaptability and customization based on project requirements. To meet a range of structural requirements and architectural styles, they are able to make roof panels in different sizes, forms, and profiles.

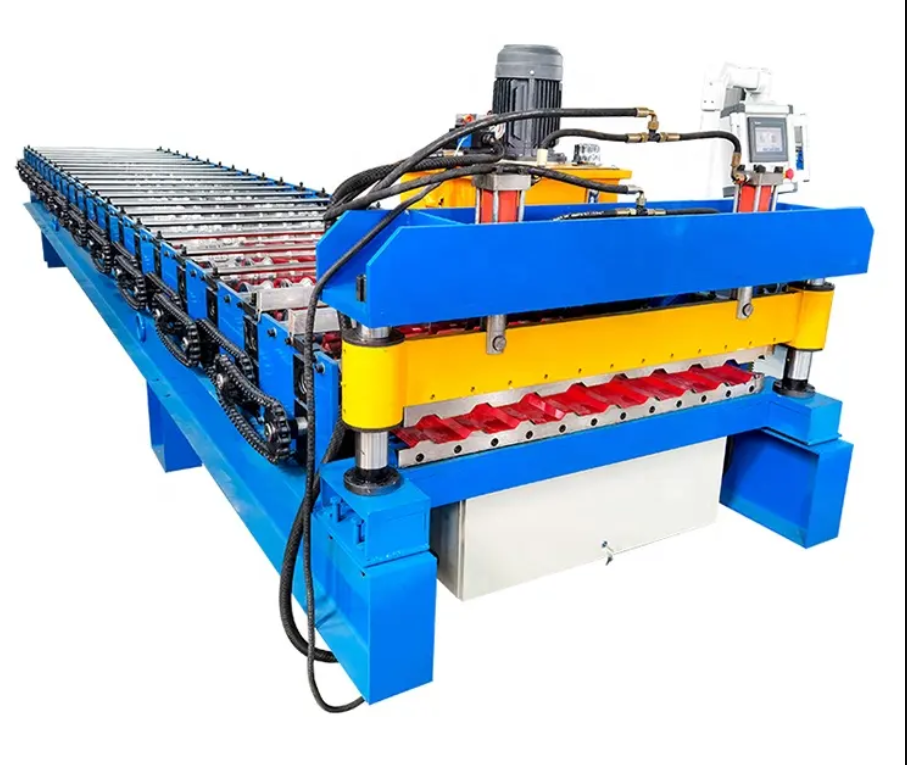

Additionally, these machines contribute to cost-effectiveness by lowering labor expenses and operational overhead. Their automated operation requires minimal manpower, leading to reduced labor costs and increased profitability for manufacturers and contractors alike.

Furthermore, metal roof panels fabricated by roll-forming machines offer superior durability and longevity, ensuring long-term performance and minimal maintenance requirements. Their resistance to corrosion, weathering, and structural degradation makes them an ideal choice for diverse applications in residential, commercial, and industrial construction projects.