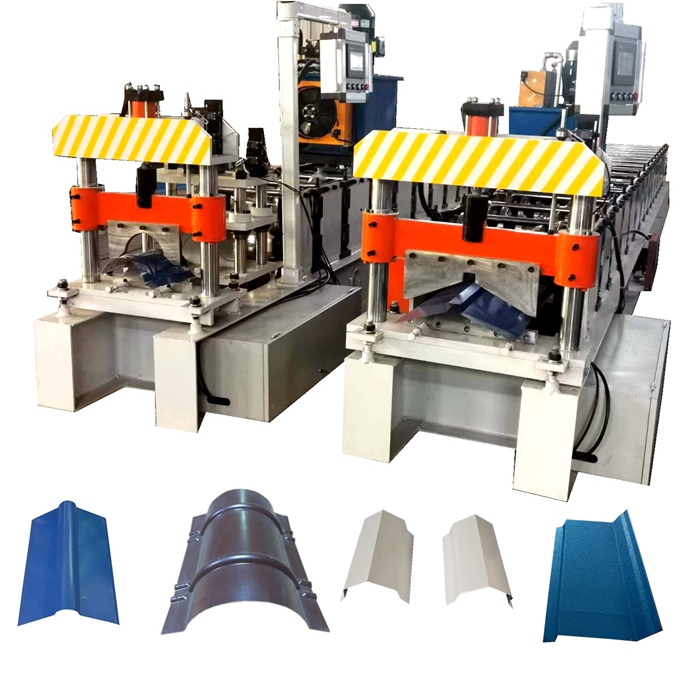

Roof Ridge Cap Forming Machine

A ridge cap roll forming machine is a specialized piece of equipment designed for efficiently producing ridge caps, which are essential components in roofing systems. This machine is specifically tailored to form metal strips into ridge caps, which are installed along the ridges of roofs to provide weatherproofing and structural integrity. By utilizing advanced roll forming technology, the machine can precisely shape the metal strips into the desired ridge cap profiles with uniform dimensions and high accuracy. This ensures consistency in quality and facilitates seamless integration with various roofing materials, contributing to the overall durability and aesthetics of the roofing system.

Working Flow of Ridge Capping Roll Forming Machine

The working flow of a ridge capping roll forming machine follows a systematic process to efficiently produce ridge caps for roofing applications. Here's a detailed overview:

Material Loading: The process starts with loading coils of raw material, typically metal strips such as galvanized steel or aluminum, onto the uncoiler of the machine. The uncoiler feeds the material into the roll forming machine.

Guiding and Feeding: The metal strip passes through a guiding system to ensure proper alignment and then enters the feeding section of the machine. This section feeds the material into the roll forming stations at a controlled rate.

Roll Forming: The metal strip moves through a series of roll forming stations, each equipped with sets of rollers that gradually shape the strip into the desired ridge cap profile. These rollers are designed to bend the metal strip accurately according to the predetermined specifications.

Cutting: Once the ridge cap profile is formed, a cutting mechanism, such as a hydraulic shear or flying cutoff, is employed to cut the continuous strip into individual ridge caps of the required length. The cutting process is synchronized with the roll forming operation to ensure precise and clean cuts.

End Product Collection: The cut ridge caps are then collected on a conveyor belt or stacking table, where they are typically stacked, bundled, or conveyed for further processing or packaging. Proper handling ensures that the ridge caps maintain their shape and quality during transportation.

Optional Additional Processes: Depending on specific requirements, additional processes such as punching holes for fastening or adding embossments for aesthetics may be integrated into the roll forming machine. These processes can be automated and synchronized with the main forming and cutting operations.

Quality Control: Throughout the production process, quality control measures are implemented to ensure that the ridge caps meet the desired standards for dimensions, shape, and surface finish. Any deviations or defects are identified and corrected promptly to maintain product quality.

Packaging and Shipping: Finally, the finished ridge caps are packaged according to customer specifications, ensuring proper protection during transportation and storage. Once packaged, the ridge caps are ready for shipping to construction sites or distribution centers.