Product Details

Steel drywall stud and track roll forming machine is widely used in drywall construction. Compared with cement construction and wooden construction,steel frame is more light and durable.Thanks to these advantages, stud and track are welcomed in construction field.

Advantages of Drywall Metalcon perfil C U channel forming machine:

1. High speed. Our high speed stud and track light keel roll forming machine speed can up to 40 m/min include punching.

2. High durable. Our rollers adopt the Cr 12 with quenched treatment,this is the best material for rollers.

3. High automatic. The full production line adopt electric decoiler, roll forming machine, conveyor, stacker and bundling system. So that is full automatic working type, save labor force.

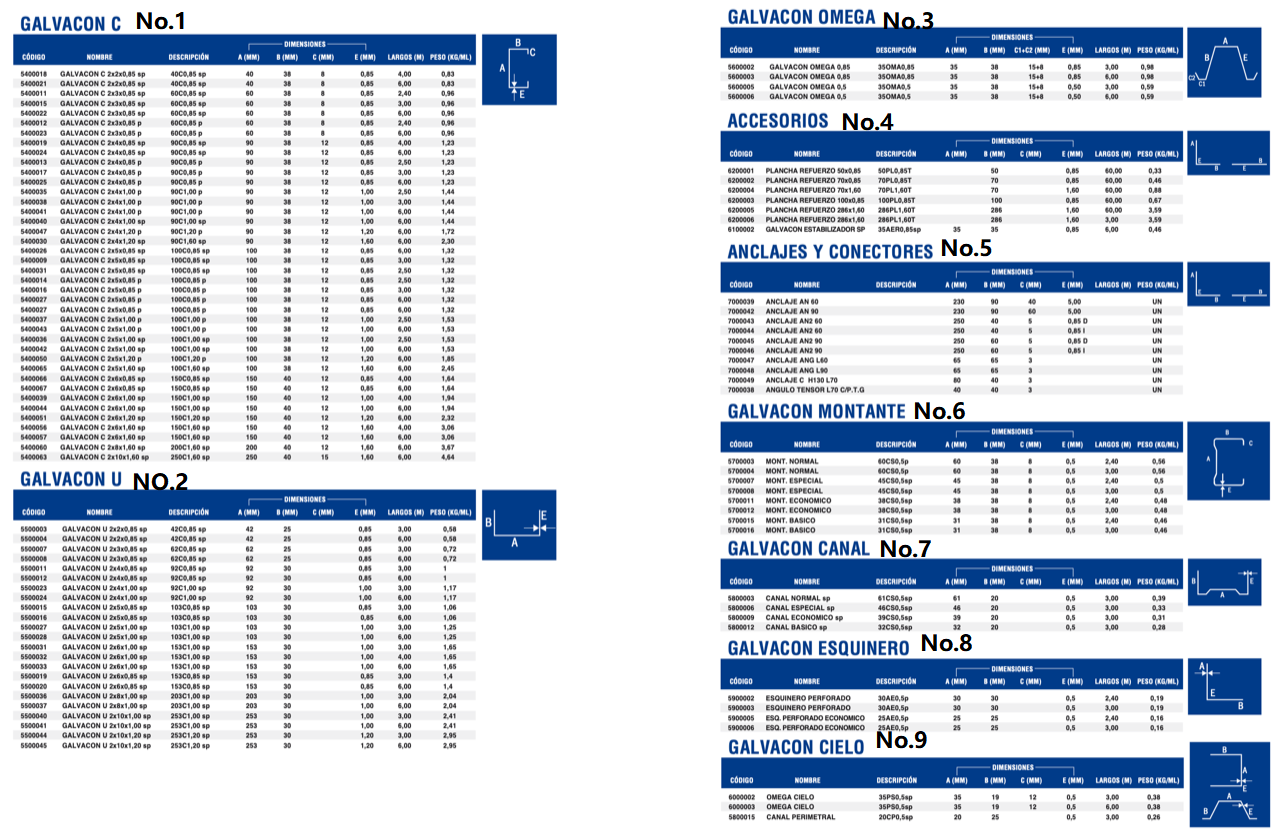

Stud and track profile drawing and picture:

One machine makes two type profiles light duty and heavy duty but the cutting blade, you need use the separated type: the thickness from 0.47 to 0.85mm. Normally from 0.47 to 0.8mm a kind of thin blades and from 0.9 to 1.5mm, better we use heavy duty cutting blade. By this way, we can make sure no shape changing during the shearing;

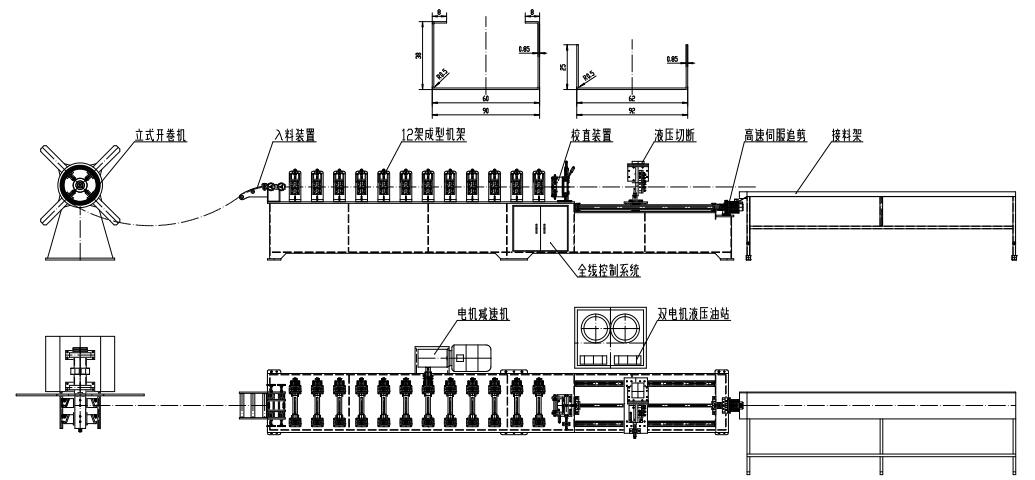

Technical Farameters

Processing Flow

|

Series

|

Details

|

Parameter

|

Comment

|

|

Material

|

Raw material

|

Steel

|

Customer confirmed

|

|

Material thickness

|

0.4-0.6 mm

|

||

|

Decoiler

|

Structure

|

Manual passive type

|

The standard one to match the production line

|

|

Single head type

|

|||

|

Loading capacity

|

1.5 Tons

|

||

|

Coil inner diameter

|

450-550 mm

|

||

|

|

Guiding device

|

Placed on the machine by seller

|

|

|

Rolling shaft material

|

45# STEEL

|

|

|

|

Shaft diameter

|

50 mm

|

|

|

|

Roller material

|

GB-Cr12

|

|

|

|

Rolling station

|

12 stations

|

|

|

|

Work speed

|

40 m/min

|

|

|

|

Machine structure

|

Vertical memorial arch frame

|

|

|

|

Machine basic frame

|

Steel plate welded

|

|

|

|

Bearing

|

Roller bearing

|

Famous brand of Harbin

|

|

|

Work power

|

4 kw

|

|

|

|

Transmission

|

By gear

|

With cover

|

|

|

Safety cover

|

available

|

|

|

|

Appearance

|

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

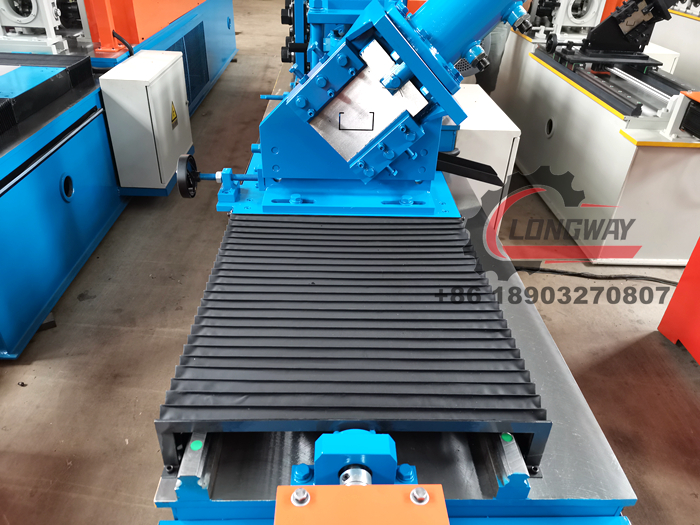

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

Non-composite conditions are common in all structures. When the gypsum board stops at the ceiling level, but the stud continues to the deck, it is a non-composite condition. Wall framing with Deflection Track, Resilient Channel (RC) or Sound Clips is a non-composite design since the screws attaching the gypsum board are not directly attached to the framing or top track. While there may be advantages to contacting Technical Services or a Design Professional, many conditions can be covered by limiting heights tables shown in this catalog .

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display