Product Details

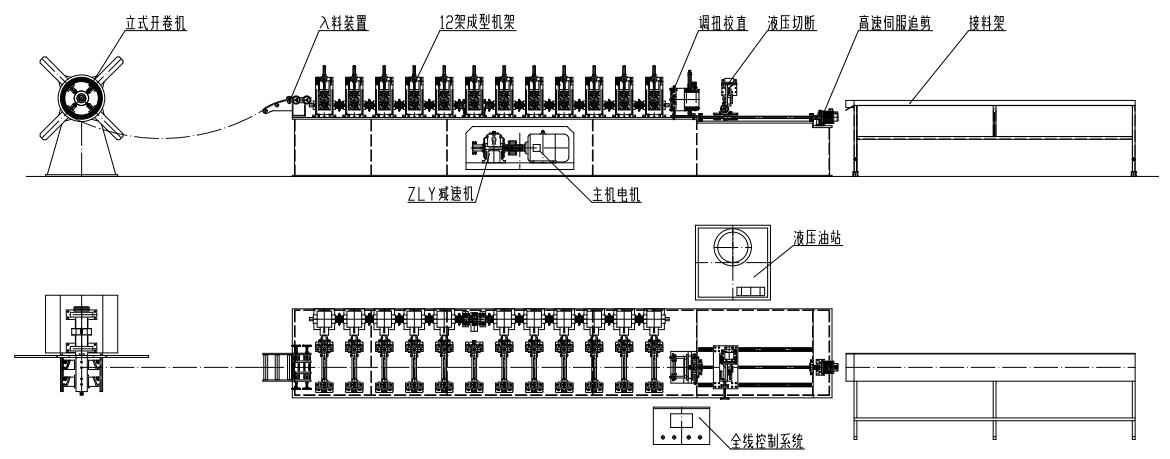

0.85mm Top hat Roof Batten Omega Roll Forming Machine is used to produce the furring channels, the ceiling batten channel, the roofing batten channel for housees. Whole ceiling batten, roofing batten machine is including below parts: 2 tons manual decoiler, leveling system, the main roll forming machine and tracking cutting system, and 2 sets output receiving table.

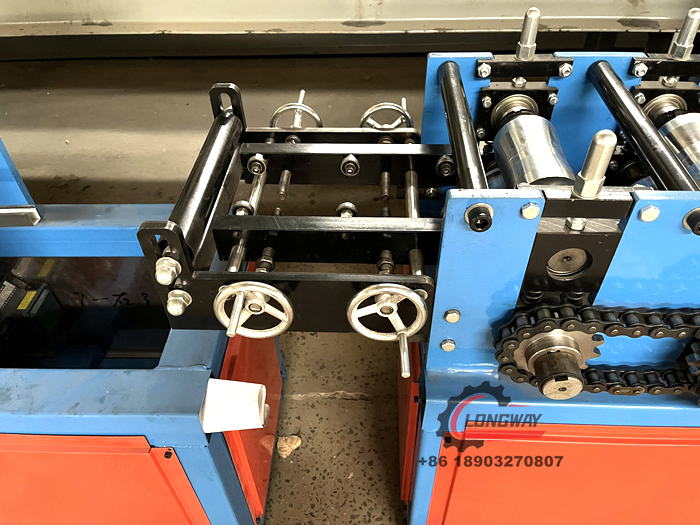

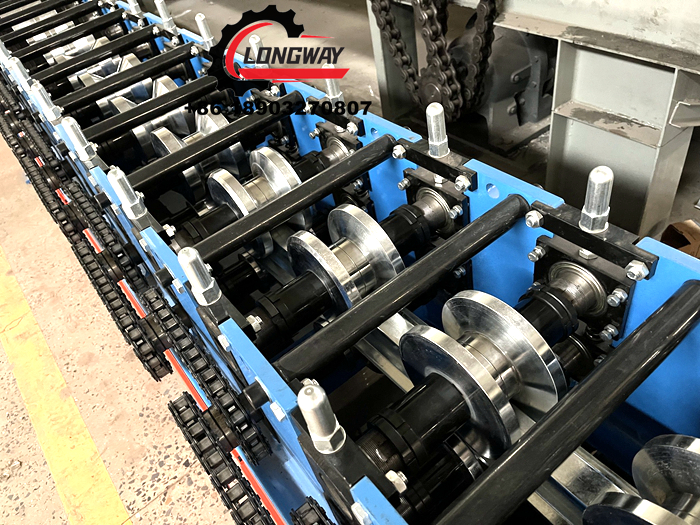

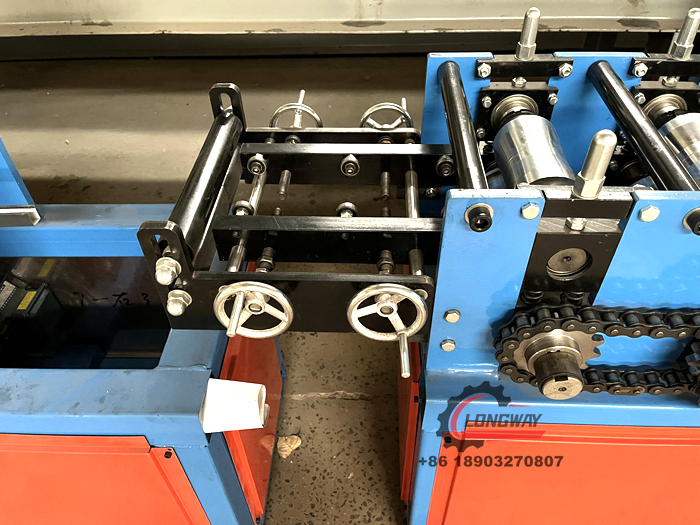

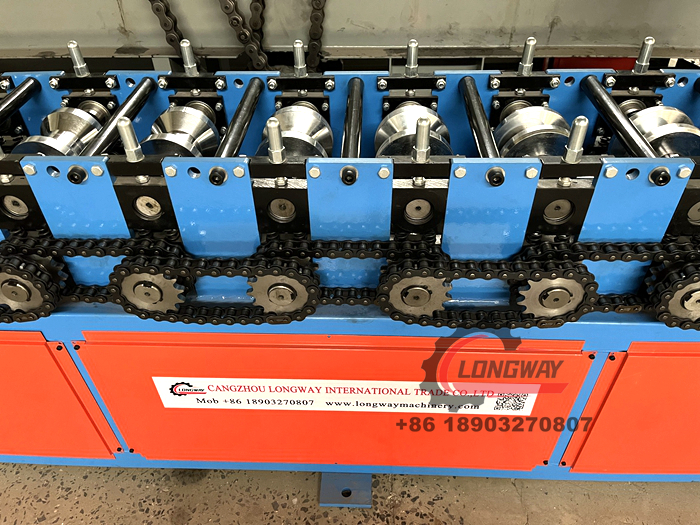

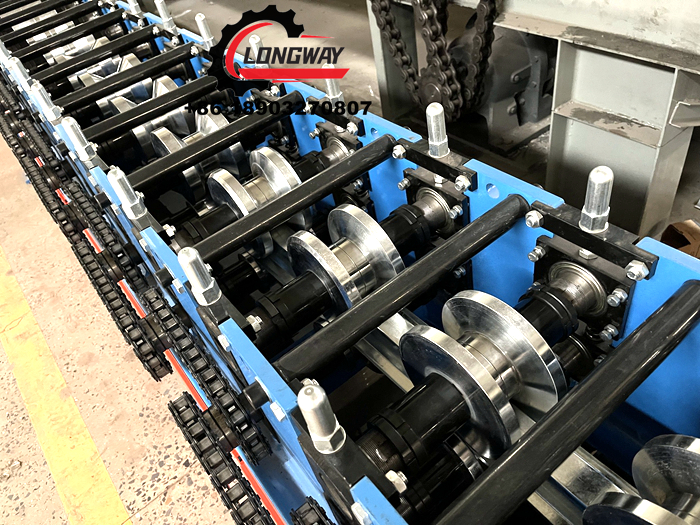

Below are some machine pictures for your reference:

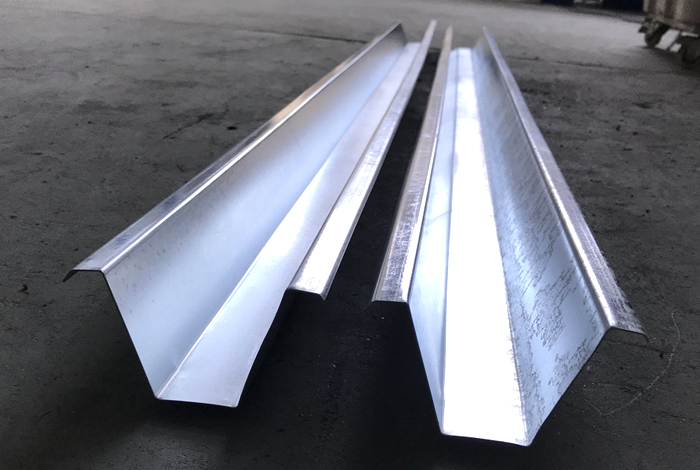

Profile drawing for reference:

Technical Farameters

Processing Flow

|

Series

|

Details

|

Parameter

|

Comment

|

|

Material

|

Raw material

|

Steel

|

Customer confirmed

|

|

Material thickness

|

0.4-0.6 mm

|

||

|

Decoiler

|

Structure

|

Manual passive type

|

The standard one to match the production line

|

|

Single head type

|

|||

|

Loading capacity

|

1.5 Tons

|

||

|

Coil inner diameter

|

450-550 mm

|

||

|

|

Guiding device

|

Placed on the machine by seller

|

|

|

Rolling shaft material

|

45# STEEL

|

|

|

|

Shaft diameter

|

50 mm

|

|

|

|

Roller material

|

GB-Cr12

|

|

|

|

Rolling station

|

12 stations

|

|

|

|

Work speed

|

40 m/min

|

|

|

|

Machine structure

|

Vertical memorial arch frame

|

|

|

|

Machine basic frame

|

Steel plate welded

|

|

|

|

Bearing

|

Roller bearing

|

Famous brand of Harbin

|

|

|

Work power

|

4 kw

|

|

|

|

Transmission

|

By gear

|

With cover

|

|

|

Safety cover

|

available

|

|

|

|

Appearance

|

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new!

|

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

0.85mm Top hat Roof Batten Omega Roll Forming Machine is used to produce the furring channel, the ceiling batten channel, the roofing batten channel for houses .

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display