Product Details

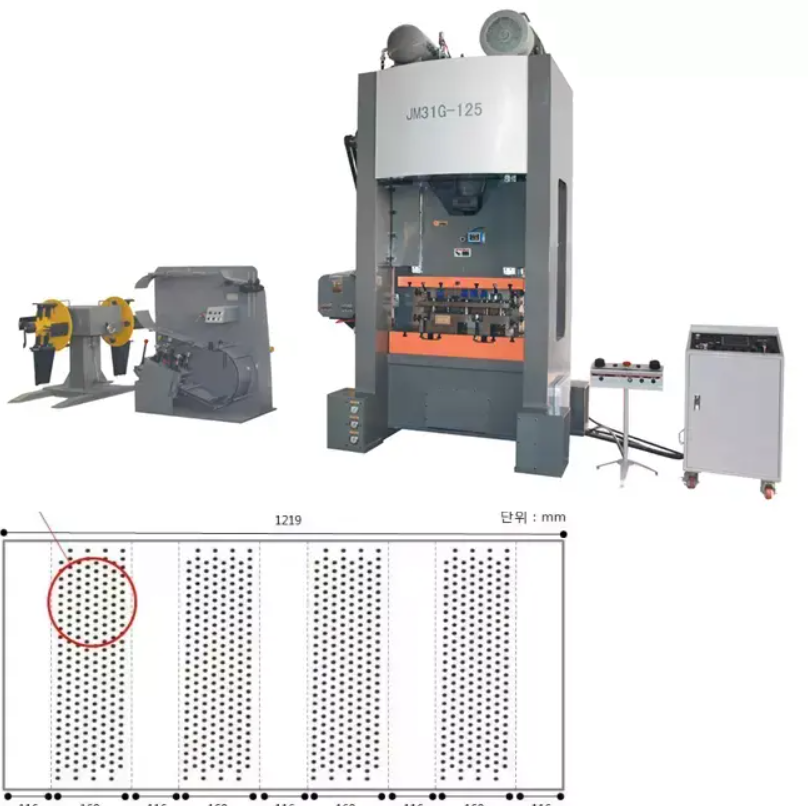

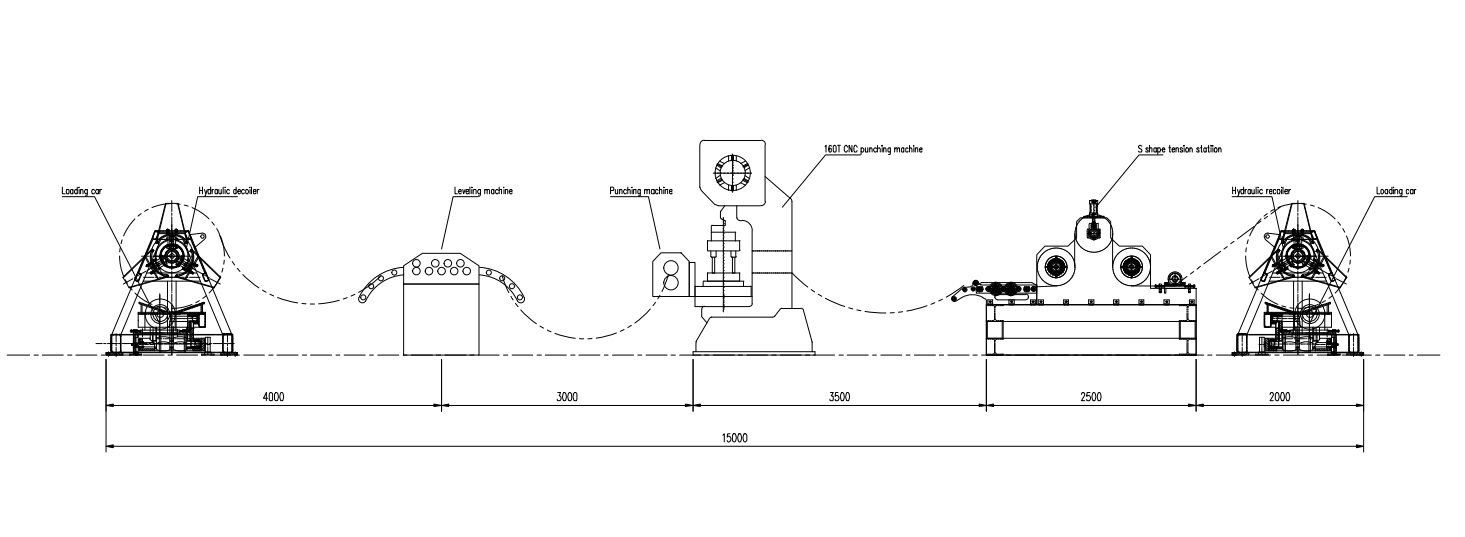

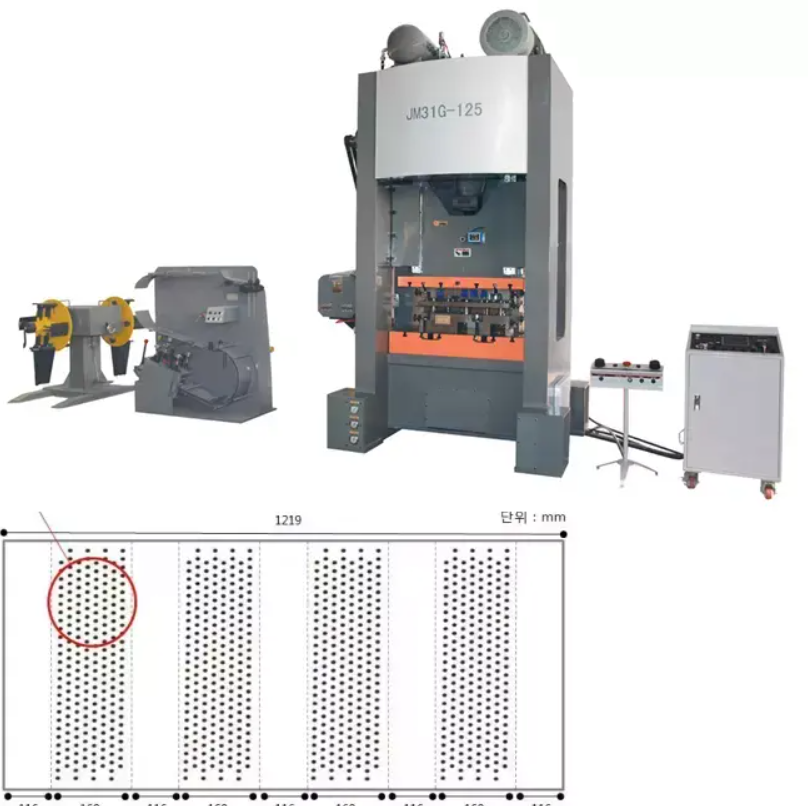

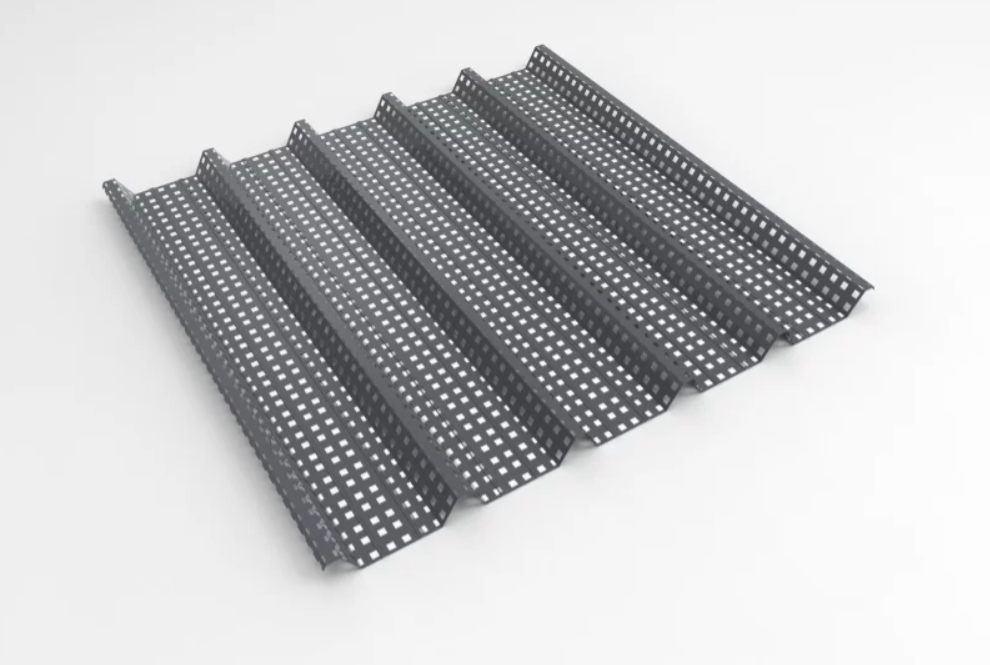

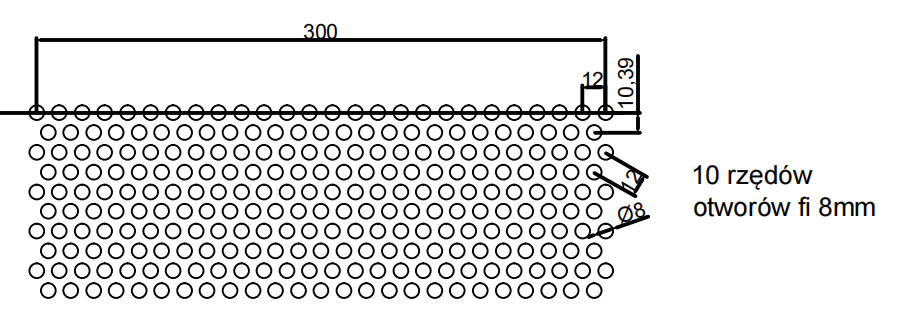

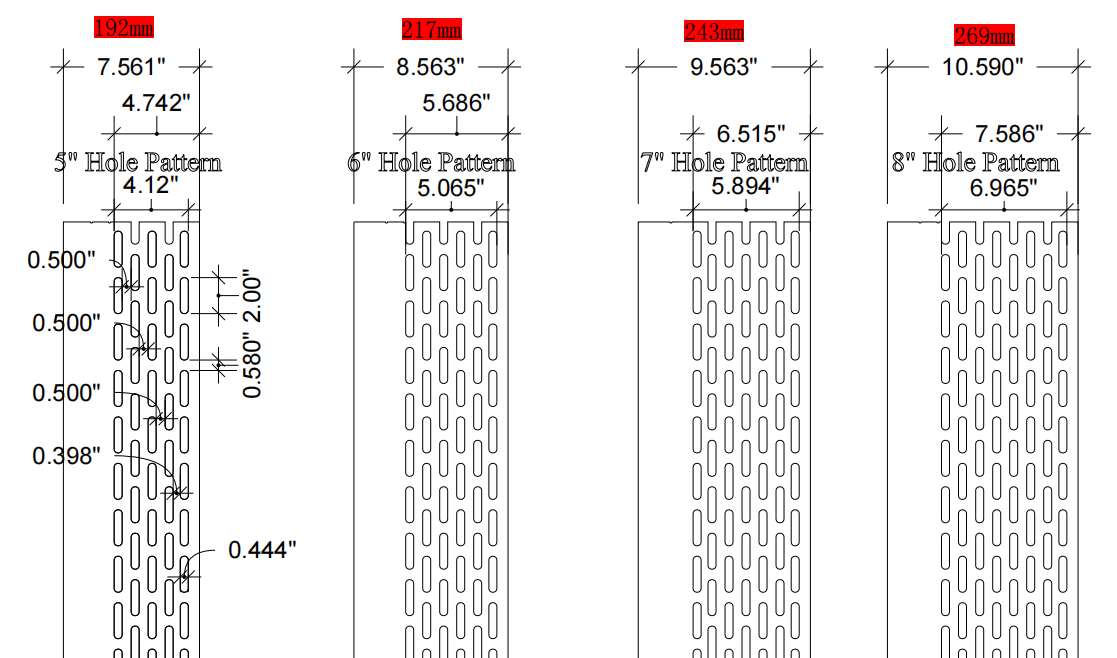

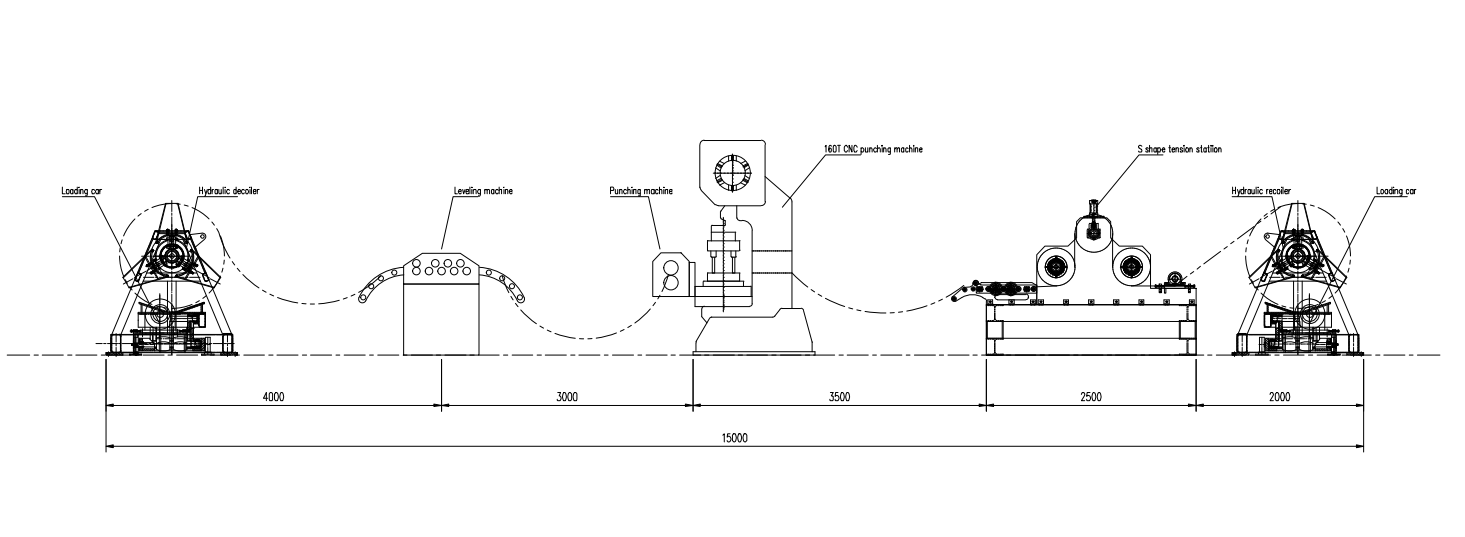

Metal sheet punching production line is designed to make the metal sheet, ALUMINIUM sheet punching and other material punching either from decoiler to recoiler or from decoiler to cut to length or only sheet punching machine. Meanwhile it also could be worked with the rolling forming machine. For example, some kind of profile needed to be punched and then do the rolling forming. So as to the punching line, it has many types combination. Here I will show you some types by some drawing profile for your reference:

Or punching could be like this:

Technical Farameters

Metal sheet punching production line working flow:

Hydraulic decoiler -- Servo feeder -- Punching -- Damping device S rollers -- Recoiler (or could be cut to length)--> or main rolling forming machines Actually all elements are optional, like you can choose manual decoiler or electrical decoiler or hydraulic decoiler. As to the punching machine, you can choose to use the high speed punching or the normal speed punching machine and then the cost will be totally different.

|

Punching Machine Parameters |

||||

|

1.Supported Material |

PPGI,GI,AI |

Thickness:0.3-2.0mm Width:1000mm/1250mm(customized) |

||

|

2.Decoiler |

Hydraulic automatic decoiler |

Manual decoiler(will give you as free) |

||

|

3.Main Punching machine |

Pressure |

200 Ton |

||

|

Diameter of shaft |

80mm solid shaft |

|||

|

Material of rollers |

45# steel, hard chrome plated on the surface |

|||

|

Machine body frame |

400 H steel |

|||

|

Drive |

Gearbox transmission |

|||

|

Dimension(L*W*H) |

15000*1800*1600(customize) |

|||

|

Weight |

18T |

|||

|

4.Cutter |

Automatic |

If you need tor cut to length |

||

|

5.Power |

Motor Power |

30 KW |

||

|

Hydraulic system power |

7.5KW |

|||

|

6.Voltage |

380V 50Hz 3Phase |

Customize |

||

|

7.Control system |

Electric Box |

Customized(famous brand) |

||

|

Language |

English(Support multiple languages) |

|||

|

PLC |

Automatic production of the whole machine. Can set batch, length, quantity, etc. |

|||

|

8.Forming Speed |

30-40m/min |

If you need to do the rolling forming |

||

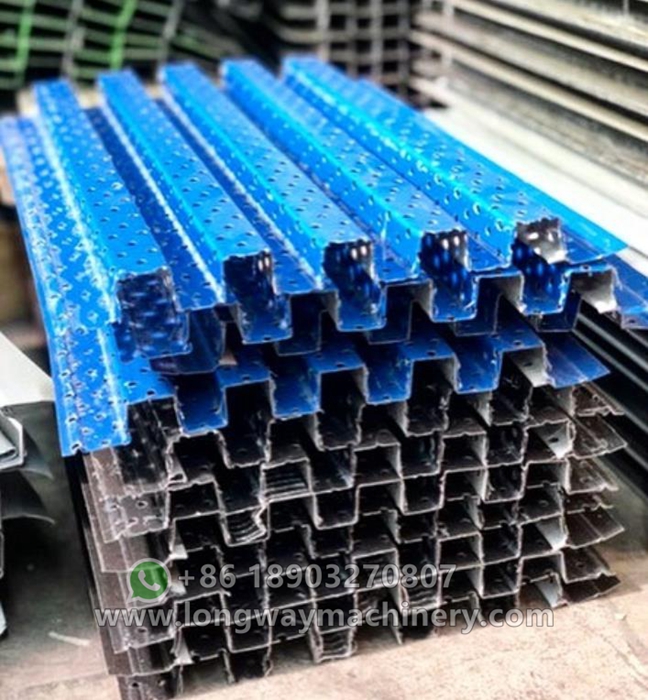

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

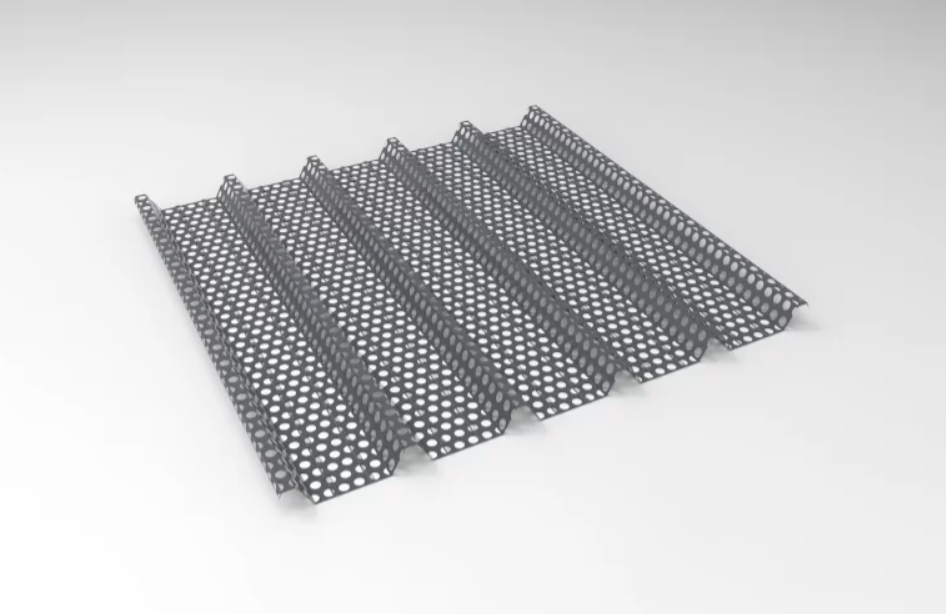

Applications

The advantage of Tr4 metal sheets includes beautiful, classica, appearance and grace taste. t is widely used in village, hotel,exhibition, vacation village, family construction and outdoor decorating.

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display