detalji o proizvodu

Wall Cladding Machine QUADRO 25X40 is designed with an overlap system that allows its installation both horizontally with visible fixings. Cladding sheet has the feature of continuous, homogeneous and orthogonal modulation.

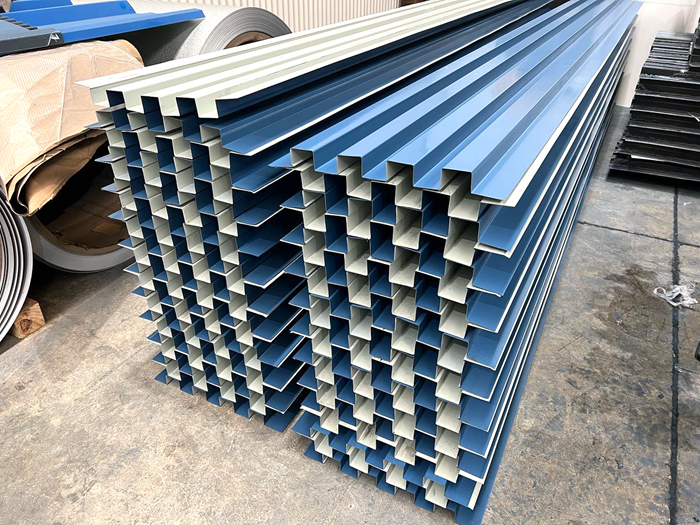

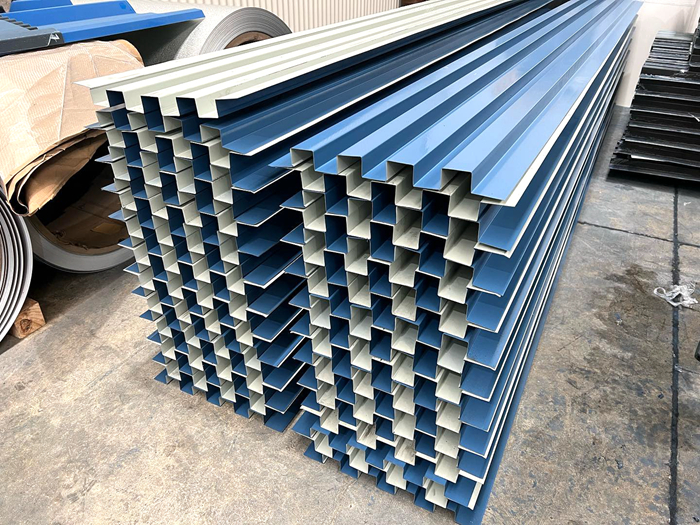

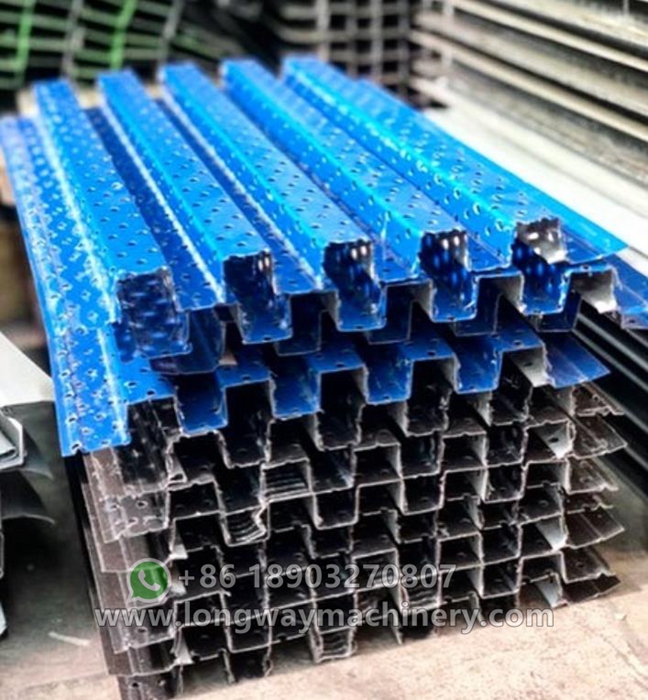

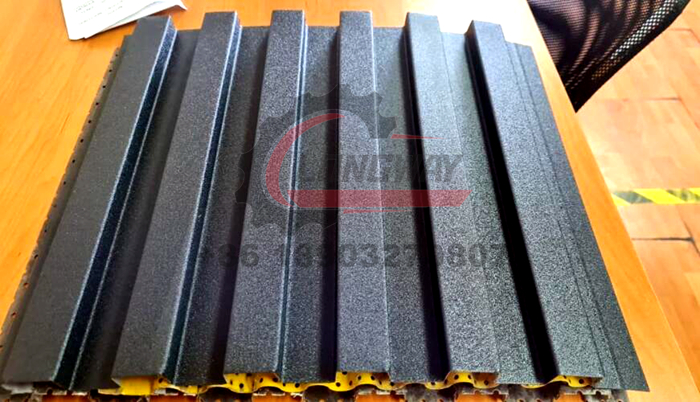

Below is the cladding wall sheets finished by our Quadro cladding roll forming machine, which received good feedback from our client . We can also design in different sizes according to your needs .

Wall Cladding Machine Advantages

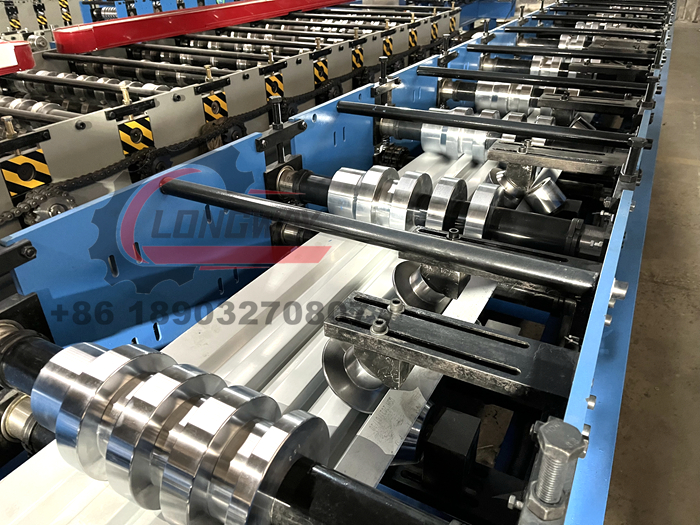

Roll Forming Process: Similar to a ceiling channel roll forming machine, a wall cladding machine utilizes a roll forming process to shape flat metal coils or sheets into the desired profile for wall cladding panels. The machine consists of multiple sets of rollers that gradually bend and form the metal to achieve the desired shape and dimensions.

Customization: The wall cladding machine can be adjusted to produce different profiles, sizes, and textures of wall cladding panels to suit the specific design preferences and requirements of construction projects. This customization capability allows for a wide range of architectural styles and design possibilities.

Efficiency and Precision: Modern cladding roll forming machines are equipped with advanced automation and computer-controlled systems, ensuring high efficiency, accuracy, and consistency in the manufacturing process. This results in uniform quality across the produced panels and helps meet tight production schedules.

Cost-Effectiveness: Wall cladding machines offer cost-effective solutions for producing large quantities of wall cladding panels compared to traditional manufacturing methods. The high-speed production capabilities and low per-unit costs make them suitable for mass production and large-scale construction projects.

Wall Cladding Machine Applications

Wall cladding panels produced by these wall cladding machines are used in various architectural and construction applications, both for exterior and interior walls. Common applications include: Wall cladding machine produced by roll forming machine supplier can provide exterior cladding for residential, commercial, and industrial buildings to enhance curb appeal, providing weather protection, and improving energy efficiency.

Interior wall cladding for decorative purposes, such as in lobbies, reception areas, retail spaces, and feature walls in homes, offices, hotels, and shopping malls.

Fire-rated cladding systems for compliance with building codes and regulations regarding fire safety.

Retrofitting existing buildings with new cladding to update their appearance, improve insulation, or address maintenance issues.

Tehnički farametri

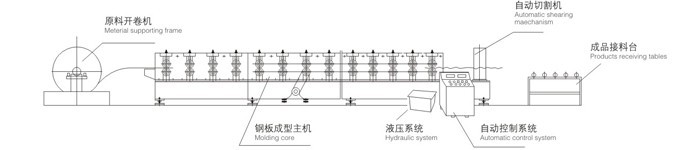

Radni proces

Odmotavanje → Ubacivanje materijala u stroj → Oblikovanje valjaka → Hidrauličko rezanje → Stol za prijem proizvoda

|

Sirovina |

Vrsta zavojnice |

PPGI, PPGL, GI |

|

Širina |

600/610 mm |

|

|

Raspon debljina |

29-22 mjerač (0,3-0,6 mm) |

|

|

Zahtjevi za napajanje

|

napon |

380v/3ph/50hz (prilagođeno) |

|

Snaga glavnog motora |

5,5+5,5kw |

|

|

Snaga rezača |

4kw |

|

|

Brzina oblikovanja |

15-20m/min |

|

|

Okvir stroja |

Struktura H grede od 350 mm |

|

|

Debljina strukture |

Srednja potporna ploča od zavarenog čelika od 18 mm |

|

|

Osovina za oblikovanje |

75 mm čvrsta osovina s toplinskom obradom |

|

|

Materijal valjaka |

Kovani čelik visoke kvalitete 45# |

|

|

Formiranje stanica |

22-26 redaka Vrsta valjanja: odvojeni koncept dizajna valjanja, može osloboditi unutarnje naprezanje iz listova, tada će ploča biti u dobroj formi i visoke preciznosti |

|

|

Put prijenosa |

Lančani pogon 1 inča (dvostruki lanac) |

|

|

Vrsta rezanja |

Hidraulički stup i rezanje po dužini |

|

|

Kontrolni sustav |

PLC Delta i Inverter Delta |

|

|

Zaslon |

Ekran na dodir |

|

|

Dimenzija (približno) |

11,5m×1,5m×1,2m |

|

|

Ukupna težina (približno) |

5.6T |

|

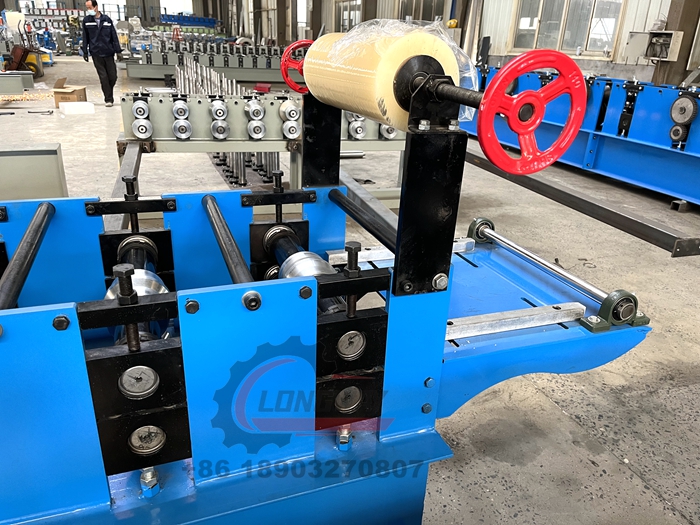

Detaljne slike stroja

Svaka komponenta može biti dizajnirana prema zahtjevima korisnika. Longway stroj za oblikovanje valjaka pruža OEM/ODM za sve kupce

Prijave

Premaz koji se koristi na fasadama, sjenilima i završnim slojevima. Dizajniran je sa sustavom preklapanja koji omogućuje njegovu horizontalnu ugradnju s vidljivim pričvršćenjima.

Povezani strojevi

LONGWAY vrijedan kupac

-

Čile

-

lran

-

filipinski

-

Južna Afrika

Paket i dostava

1 .Prskanje antikorozivnog ulja na valjke kako bi se spriječila oksidacija valjaka tijekom transporta

2. Izolacijska folija za pakiranje cijelog stroja kako bi se spriječila oksidacija stroja tijekom transporta

3.Razumno planiranje prostora za smanjenje troškova prijevoza za kupce

4. Dobro fiksiran kako bi se spriječilo oštećenje stroja tijekom razdoblja prijevoza

Tvornički zaslon