Detalles de producto

Wall Cladding Machine QUADRO 25X40 is designed with an overlap system that allows its installation both horizontally with visible fixings. Cladding sheet has the feature of continuous, homogeneous and orthogonal modulation.

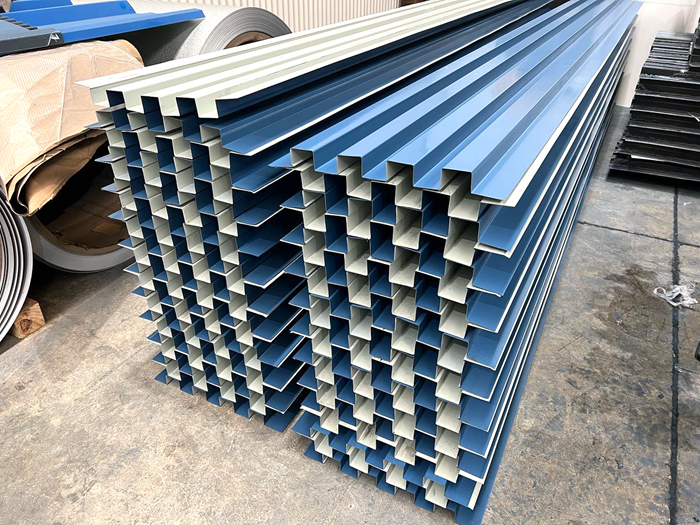

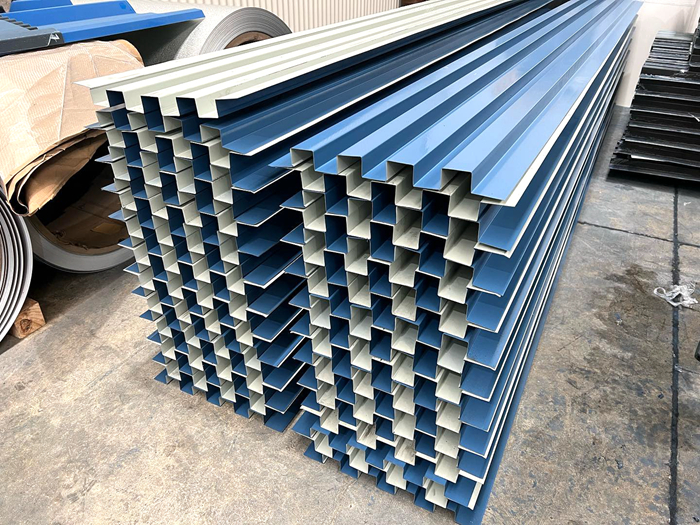

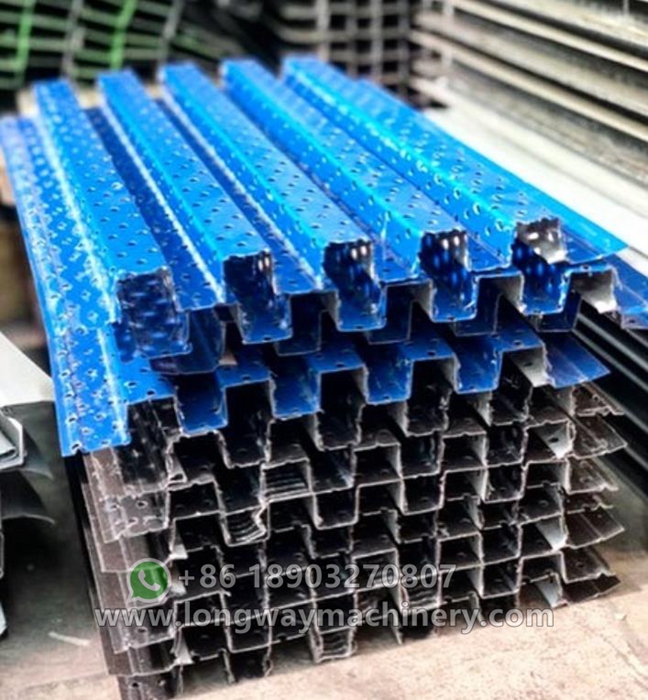

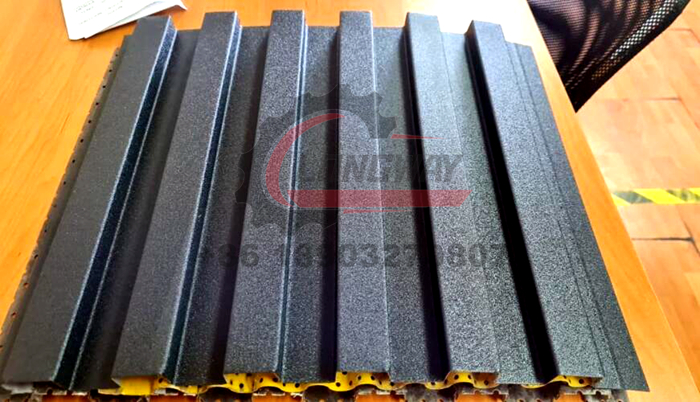

Below is the cladding wall sheets finished by our Quadro cladding roll forming machine, which received good feedback from our client . We can also design in different sizes according to your needs .

Wall Cladding Machine Advantages

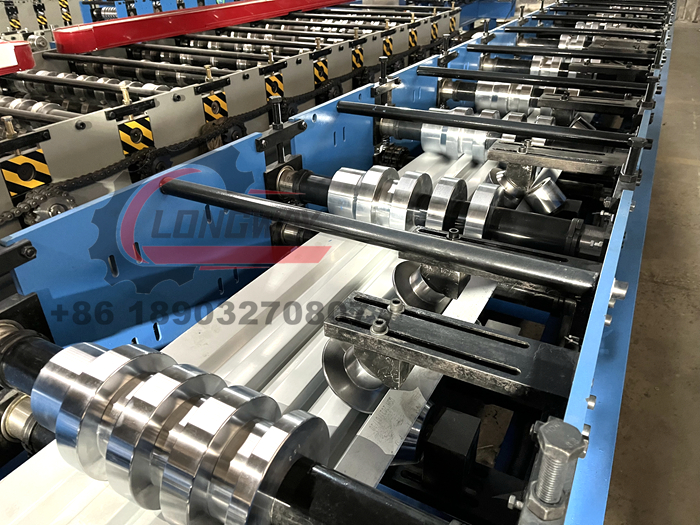

Roll Forming Process: Similar to a ceiling channel roll forming machine, a wall cladding machine utilizes a roll forming process to shape flat metal coils or sheets into the desired profile for wall cladding panels. The machine consists of multiple sets of rollers that gradually bend and form the metal to achieve the desired shape and dimensions.

Customization: The wall cladding machine can be adjusted to produce different profiles, sizes, and textures of wall cladding panels to suit the specific design preferences and requirements of construction projects. This customization capability allows for a wide range of architectural styles and design possibilities.

Efficiency and Precision: Modern cladding roll forming machines are equipped with advanced automation and computer-controlled systems, ensuring high efficiency, accuracy, and consistency in the manufacturing process. This results in uniform quality across the produced panels and helps meet tight production schedules.

Cost-Effectiveness: Wall cladding machines offer cost-effective solutions for producing large quantities of wall cladding panels compared to traditional manufacturing methods. The high-speed production capabilities and low per-unit costs make them suitable for mass production and large-scale construction projects.

Wall Cladding Machine Applications

Wall cladding panels produced by these wall cladding machines are used in various architectural and construction applications, both for exterior and interior walls. Common applications include: Wall cladding machine produced by roll forming machine supplier can provide exterior cladding for residential, commercial, and industrial buildings to enhance curb appeal, providing weather protection, and improving energy efficiency.

Interior wall cladding for decorative purposes, such as in lobbies, reception areas, retail spaces, and feature walls in homes, offices, hotels, and shopping malls.

Fire-rated cladding systems for compliance with building codes and regulations regarding fire safety.

Retrofitting existing buildings with new cladding to update their appearance, improve insulation, or address maintenance issues.

Parámetros técnicos

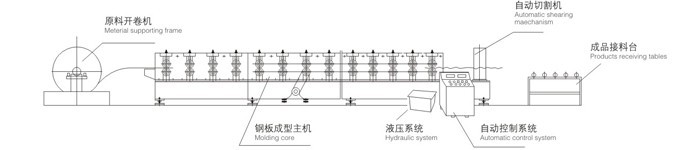

Proceso de trabajo

Desenrollado → Material de alimentación en la máquina → Perfilado → Corte hidráulico → Mesa de recepción de productos

|

Materia prima |

Tipo de bobina |

PPGI, PPGL, GI |

|

Ancho |

600/610 mm |

|

|

Rango de espesor |

Calibre 29-22 (0,3-0,6 mm) |

|

|

Requisitos de energía

|

Voltaje |

380v/3ph/50hz(Personalizado) |

|

Potencia del motor principal |

5.5+5.5kw |

|

|

Poder de corte |

4kw |

|

|

Velocidad de formación |

15-20 m/min |

|

|

Marco de la máquina |

Estructura de viga H de 350 mm |

|

|

Espesor de la estructura |

Placa de soporte central de acero soldado de 18 mm |

|

|

Eje de formación |

Eje macizo de 75 mm con tratamiento térmico |

|

|

Material de los rodillos |

Acero forjado de alto grado 45# |

|

|

Estaciones de formación |

22-26 filas Tipo de rodadura: concepto de diseño de rodadura separado, puede liberar la tensión interna de los pies, entonces la hoja estará en buena forma y con alta precisión |

|

|

Forma de transmisión |

Transmisión por cadena de 1 pulgada (Cadena doble) |

|

|

tipo de corte |

Corte tipo Pilar Hidráulico y corte longitudinal |

|

|

Sistema de control |

Delta del PLC y delta del inversor |

|

|

Pantalla |

Pantalla táctil |

|

|

Dimensión (aprox.) |

11,5 mx 1,5 mx 1,2 m |

|

|

Peso total (aproximado) |

5.6T |

|

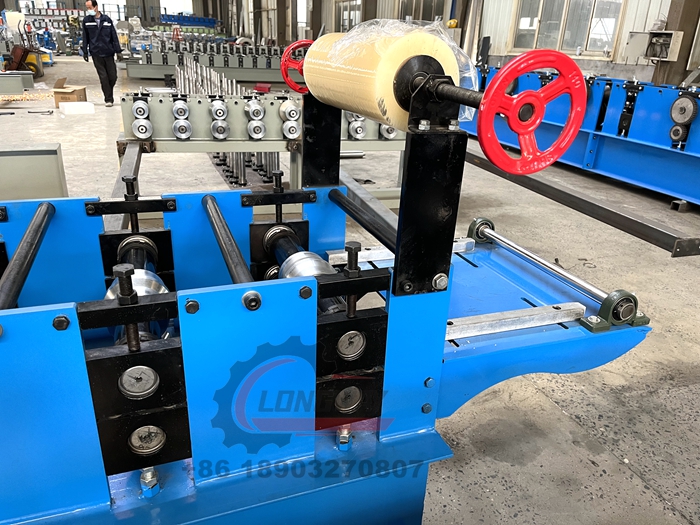

Imágenes detalladas de la máquina

Cada componente se puede diseñar según las necesidades personalizadas. La máquina formadora de rollos Longway proporciona OEM/ODM para todos los clientes

Aplicaciones

Revestimiento usado en fachadas, cortavistas y terminaciones. Está diseñado con un sistema de traslapo que permite su instalación tanto de manera horizontal con fijaciones a la vista.

Máquinas relacionadas

Cliente valioso de LONGWAY

-

Chile

-

Irán

-

filipino

-

Sudáfrica

Paquete y Entrega

1. Pulverización de aceite anticorrosivo en los rodillos para evitar la oxidación de los rodillos durante el envío

2. Máquina completa de película de aislamiento de embalaje para evitar la oxidación de la máquina durante el envío

3. Planificación de espacio razonable para reducir los costos de transporte para los clientes.

4. Bien arreglado para evitar daños a la máquina durante el período de tránsito

Pantalla de fábrica