The Portable Clip lock Flashing Roll Forming Machine is used to make unexposed screw roof sheet, with the advantage of sizes adjustable and working at site .

Firstly, the standing seam roof panels have a concealed fixing or seaming method by turning up the edges of two adjacent panels, and then folding or interlocking them. In this way, the seaming or fixing parts are invisible, and therefore sometimes we called the panels concealed fixing panels!

The material thickness varies from 0.4-0.8mm,in some places such as USA,they use copper as raw material. But some other concealed fix standing seam roofing, likebemo roof sheet are thicker from 0.8-1.2mm.

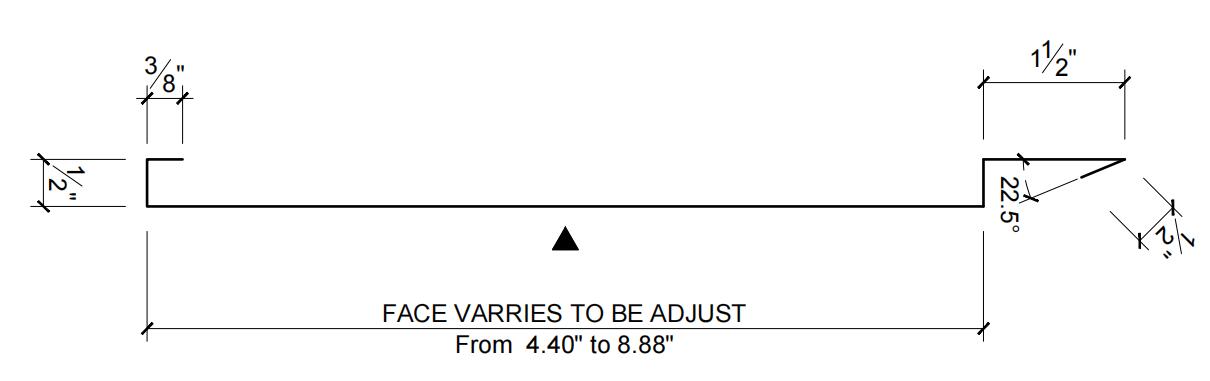

Flashing Profile Drawing for reference :

Drip edge is metal flashing installed at the edges of the roof to keep water away from your fascia and from getting underneath your roofing components.

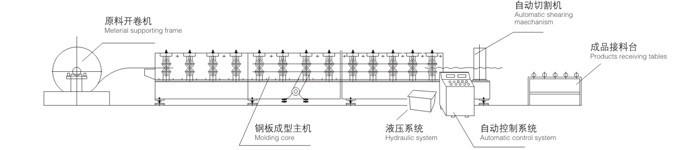

Processing Flow

|

Metal Roofing Flashing profile Forming Machine Parameters

|

|

|

Raw Material

|

PPGI

|

|

Material Thickness: 0.46Mm

|

|

|

Machine Frame

|

20mm thick steel wall plate welding

|

|

Machine Structure

|

Vertical Arch Frame Structure

|

|

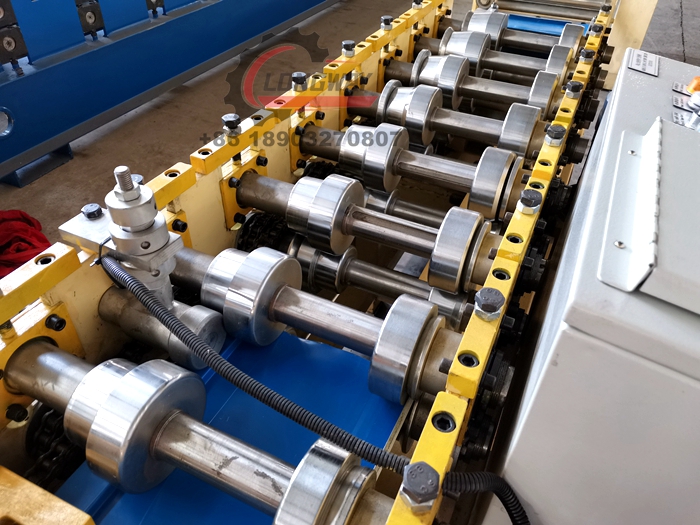

Material Of Rollers

|

GCr12 quenched

|

|

Forming stations

|

10 stations

|

|

Diameter of shafts

|

Φ50mm

|

|

Material of shafts

|

45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness

|

|

Forming speed

|

About 15m/min

|

|

Voltage

|

380v 50hz 3phase Or As local customer request

|

|

Transmission

|

Gear Transmission

|

|

Material Of Gear: 20 Crmnti

|

|

|

Work power

|

11 kw

|

|

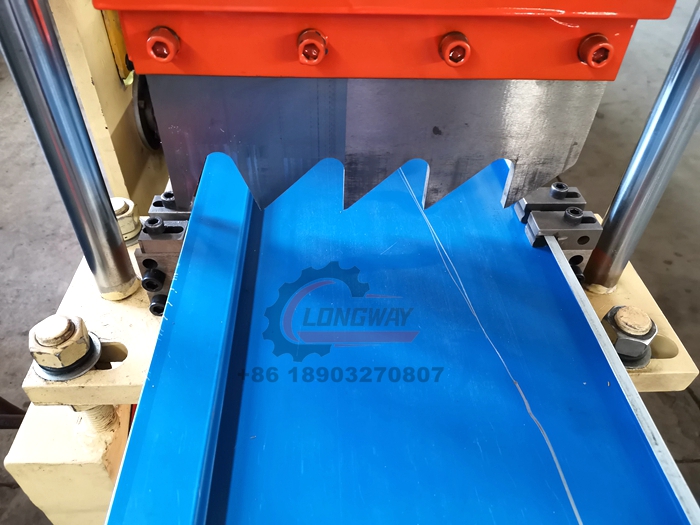

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

Cutting type

|

Hydraulic servo cutting

|

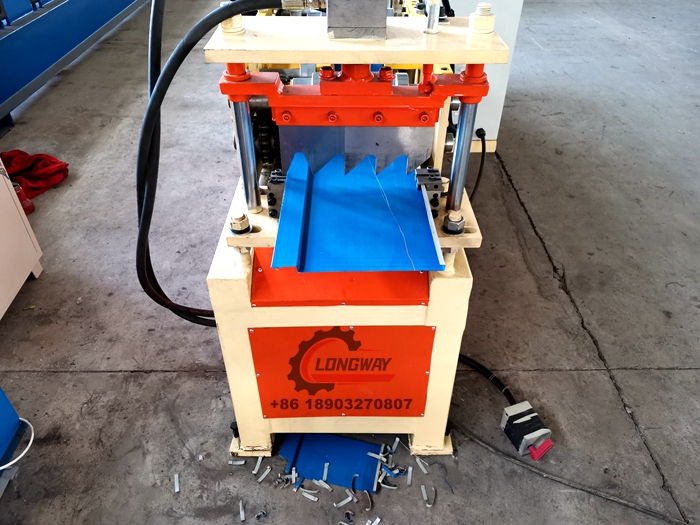

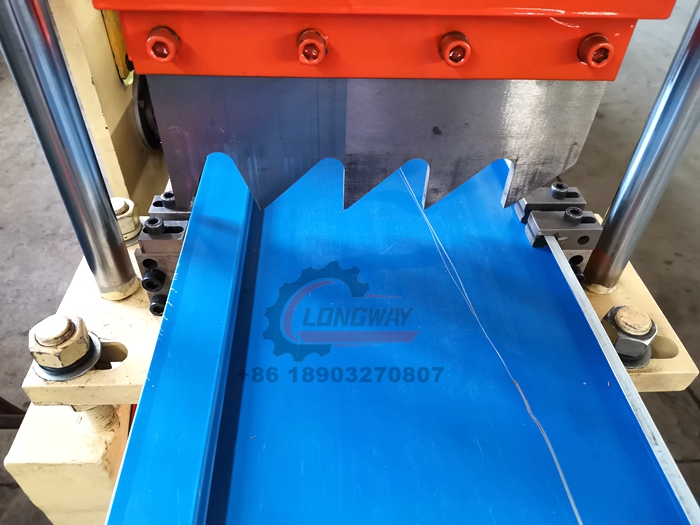

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

The advantage of Tr4 metal sheets includes beautiful, classica, appearance and grace taste. t is widely used in village, hotel,exhibition, vacation village, family construction and outdoor decorating.

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display