Product Details

Technical Farameters

Steel door frame roll forming machine Processing flow:

Manual de coiler→Guide roller→Feeding material →Leveling→punching→roll forming→strengthening→Hydraulic cutting→product receiving table

|

Material |

Raw material |

Galvanized |

||||

|

Thickness |

0.65-1mm |

|||||

|

Material hardness: |

550 MPA---350 MPA |

|||||

|

Manual decoiler |

Inner Diameter: 450-550mm |

Expand by manual |

||||

|

Max Coil width:300mm |

||||||

|

Capacity: 3T |

||||||

|

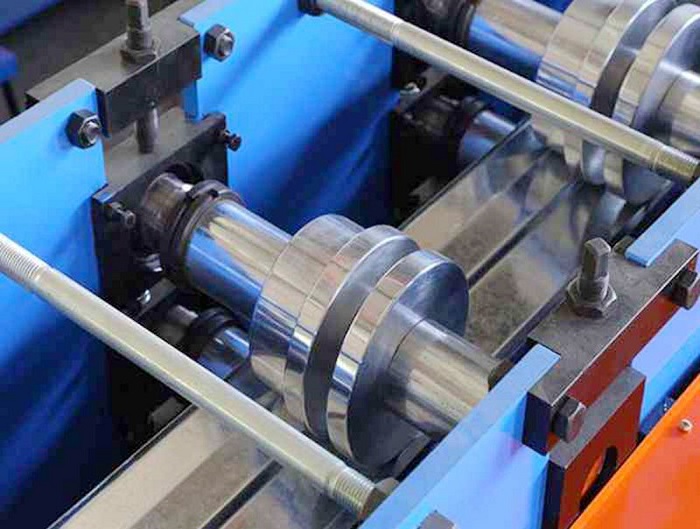

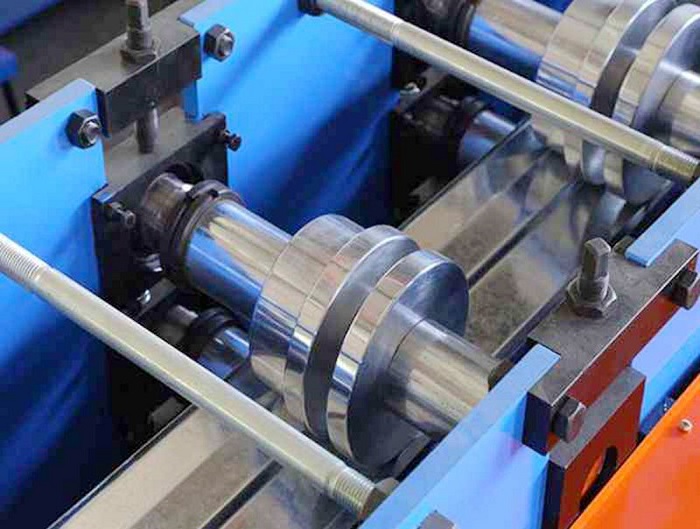

Main Forming machine |

Forming steps |

16stations |

||||

|

Shaft diameter |

50mm |

|||||

|

Design type |

middle plate welded,Memorial arch frame type |

|||||

|

Frame thickness |

25mm |

|||||

|

roller material |

||||||

|

45# steel with tempering |

||||||

|

Work speed |

0-15m/min |

|||||

|

Transport |

By gear |

|||||

|

Power of main machine |

5.5 kw |

|||||

|

Power supply |

Hydraulic station |

|||||

|

punching mould material |

GCr12MoV |

|||||

|

Blade mould material |

||||||

|

no distorting or wasting. High level safety factor. |

||||||

|

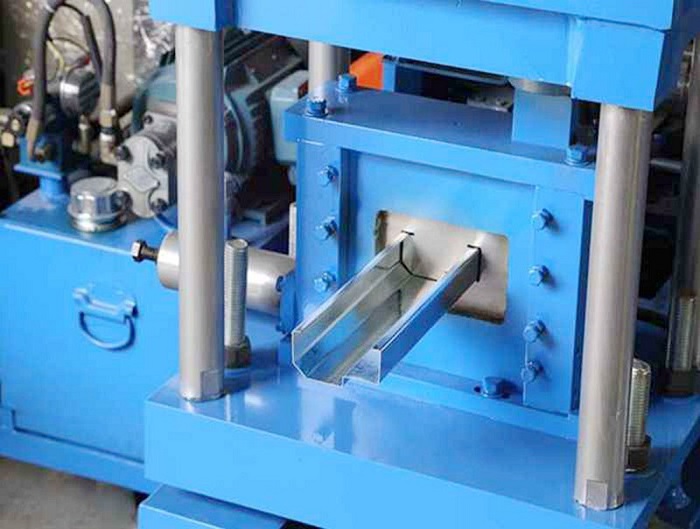

Hydraulic system |

Hydraulic oil |

46# |

||||

|

Power |

3kw |

|||||

|

Cutting length |

As required |

|||||

|

No distorting or wasting. High level safety factor. |

||||||

|

Control Device |

control |

By PLC |

||||

|

PLC language |

English and Chinese (or as required) |

|||||

|

Screen |

Touch screen |

|||||

|

Function |

Automatic length ,punching and quantity measurement |

|||||

|

Other Spare part |

Weight |

About 3 ton |

||||

|

Dimension |

4300*800*1400mm L*W*H |

|||||

|

Main body color |

As you need |

|||||

|

Voltage |

380v/50hz/3ph(or as required) |

|||||

|

Spare cutting blade |

One piece |

|||||

|

Fuse |

2 pieces |

|||||

|

Relay |

2 pieces |

|||||

|

Travel switch |

2 pieces |

|||||

|

Solenoid valve |

1 pieces |

|||||

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

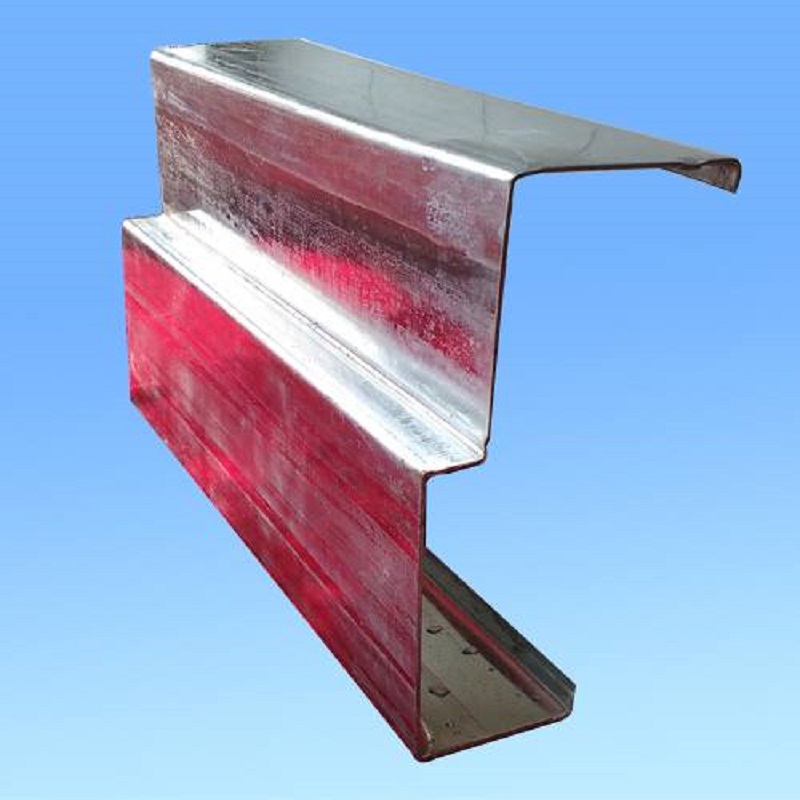

Applications

Metal Door Frames are easily fitted during construction or can be retrofitted. They are easier to fit, more versatile, stronger and more resilient and provide an excellent surface finish.

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display