News

-

we detailed the advantages of press braking, comparing it to roll forming as a metal fabrication bending process. Although they have little in common, other than the process category, both are important and have many uses. More than anything, choosing one over the other depends mainly on the end product undergoing fabrication. This week, we’ll take a look at closer look at roll forming specifically.Read more

we detailed the advantages of press braking, comparing it to roll forming as a metal fabrication bending process. Although they have little in common, other than the process category, both are important and have many uses. More than anything, choosing one over the other depends mainly on the end product undergoing fabrication. This week, we’ll take a look at closer look at roll forming specifically.Read more -

Roll forming is superior to other metal forming processes and has advantages over aluminum extrusions, for many reasons.Read more

Roll forming is superior to other metal forming processes and has advantages over aluminum extrusions, for many reasons.Read more -

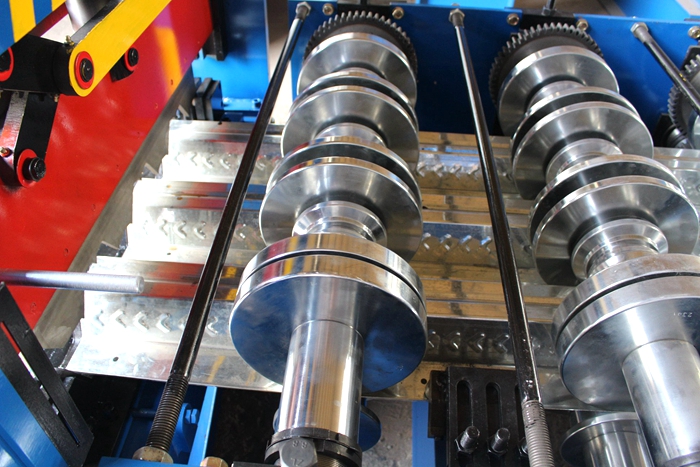

A roll former may appear to be a tremendously complex machine, with its wide array of stations and high speeds. It’s worth learning about how it works because it can perform a unique function and create identical end products consistently that meet the strictest of specifications.Read more

A roll former may appear to be a tremendously complex machine, with its wide array of stations and high speeds. It’s worth learning about how it works because it can perform a unique function and create identical end products consistently that meet the strictest of specifications.Read more -

Roll forming is a flexible, responsive and cost-effective alternative to extrusion, press braking, and stamping.Read more

Roll forming is a flexible, responsive and cost-effective alternative to extrusion, press braking, and stamping.Read more -

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.Read more

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.Read more -

Stud and track roll forming machines are one of the most versatile types of machinery, as you can produce a wide variety of structural steel shapes with them. The five best stud and track roll forming machines on this list all have the ability to shape a range of different sizes, from short pieces all the way up to long.Read more

Stud and track roll forming machines are one of the most versatile types of machinery, as you can produce a wide variety of structural steel shapes with them. The five best stud and track roll forming machines on this list all have the ability to shape a range of different sizes, from short pieces all the way up to long.Read more -

In modern buildings, people tend to use steel because steel is lightweight, recyclable, costs less money and time, compared to traditional clays, stones or bricks. In a lightweight or light gauge steel building, most of building materials are made of steel, and most of these steel building materials are manufactured by roll forming machines, one of which is drywall stud and track roll forming machine that has been designed for the continuous and automatic production of metal c stud and u tracks applied for both exterior and partition walls in both individual and industrial buildings.Read more

In modern buildings, people tend to use steel because steel is lightweight, recyclable, costs less money and time, compared to traditional clays, stones or bricks. In a lightweight or light gauge steel building, most of building materials are made of steel, and most of these steel building materials are manufactured by roll forming machines, one of which is drywall stud and track roll forming machine that has been designed for the continuous and automatic production of metal c stud and u tracks applied for both exterior and partition walls in both individual and industrial buildings.Read more -

Stud and track roll forming machine could be used to make single stud, single track or combine track and stud by one machine. The sizes could be customized according to customer requirements. And meanwhile one machine could be used to make many types of the sizes and shapes. Our Stud and track roll forming machine also allows you to press logo, punching company name or print date you need on the finished products.Read more

Stud and track roll forming machine could be used to make single stud, single track or combine track and stud by one machine. The sizes could be customized according to customer requirements. And meanwhile one machine could be used to make many types of the sizes and shapes. Our Stud and track roll forming machine also allows you to press logo, punching company name or print date you need on the finished products.Read more -

Metal Stud and Track Forming Machine for Light construction use. Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction workRead more

Metal Stud and Track Forming Machine for Light construction use. Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction workRead more -

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Read more

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Read more -

A Metal Stud Profile Machine has become an increasingly popular choice for manufacturers in the building industry who are looking to produce precision punching and cutting with a roll former that can easily be adjusted to different dimensions as required.Read more

A Metal Stud Profile Machine has become an increasingly popular choice for manufacturers in the building industry who are looking to produce precision punching and cutting with a roll former that can easily be adjusted to different dimensions as required.Read more -

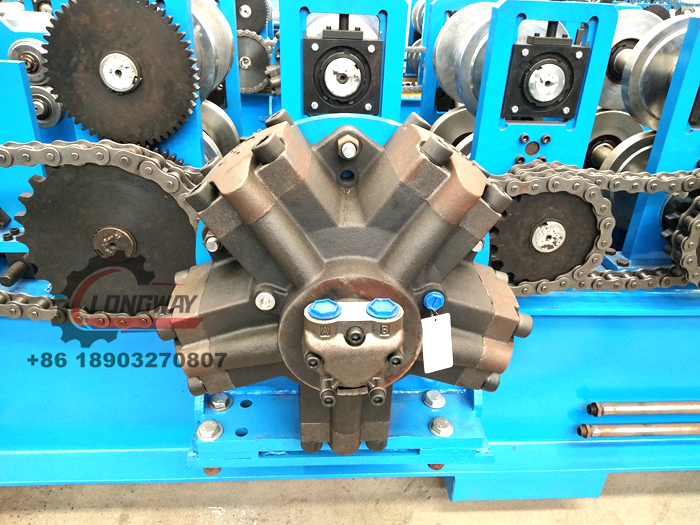

This wall stud roll forming machine produces multi-profiles and size-changing by the spacer. in fact, it is Multi size wall stud and tracks machine for multi-profiles,size-changing by the spacer. there is an Enlarged hydraulic station to ensure high-speed working. Easy operation, low maintenance cost.Read more

This wall stud roll forming machine produces multi-profiles and size-changing by the spacer. in fact, it is Multi size wall stud and tracks machine for multi-profiles,size-changing by the spacer. there is an Enlarged hydraulic station to ensure high-speed working. Easy operation, low maintenance cost.Read more