News

-

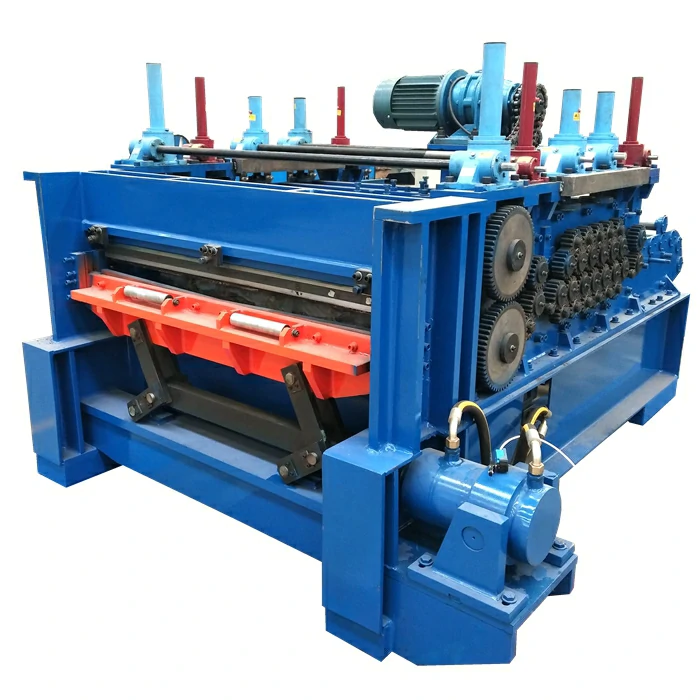

One of the most common building and construction materials is the steel stud and track. The machine that is used to form these steel studs and track is the �Stud Roll Forming Machine�. The common configuration includes advanced features such as automatic material thickness (gauge) control and material handling systems.Read more

One of the most common building and construction materials is the steel stud and track. The machine that is used to form these steel studs and track is the �Stud Roll Forming Machine�. The common configuration includes advanced features such as automatic material thickness (gauge) control and material handling systems.Read more -

In modern buildings, people tend to use steel because steel is lightweight, recyclable, costs less money and time, compared to traditional clays, stones or bricks. In a lightweight or light gauge steel building, most of building materials are made of steel, and most of these steel building materials are manufactured by roll forming machines, one of which is drywall stud and track roll forming machine that has been designed for the continuous and automatic production of metal c stud and u tracks applied for both exterior and partition walls in both individual and industrial buildings.Read more

In modern buildings, people tend to use steel because steel is lightweight, recyclable, costs less money and time, compared to traditional clays, stones or bricks. In a lightweight or light gauge steel building, most of building materials are made of steel, and most of these steel building materials are manufactured by roll forming machines, one of which is drywall stud and track roll forming machine that has been designed for the continuous and automatic production of metal c stud and u tracks applied for both exterior and partition walls in both individual and industrial buildings.Read more -

Metal stud and track roll forming machine is used to produce the main channel and furring channel such as the c channel , u channel , omega profile and L angel .Read more

Metal stud and track roll forming machine is used to produce the main channel and furring channel such as the c channel , u channel , omega profile and L angel .Read more -

In the ever-evolving field of construction, innovation is key. The “Steel Stud Roll Forming Machine” has emerged as a transformative technology, revolutionizing the production of steel studs used in various structural applications.Read more

In the ever-evolving field of construction, innovation is key. The “Steel Stud Roll Forming Machine” has emerged as a transformative technology, revolutionizing the production of steel studs used in various structural applications.Read more -

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Read more

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Read more -

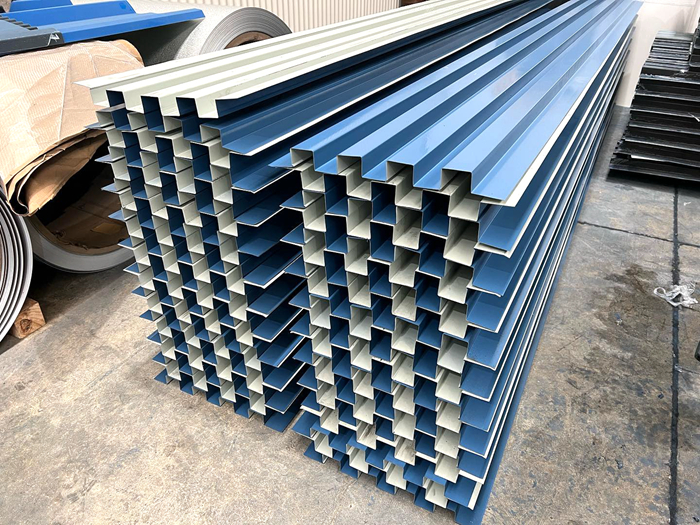

A Stud and Track Roll Forming Machine is an industrial device used to create steel studs and tracks – essential components in drywall, wall partition, and ceiling constructions. The machine takes metal strips and progressively shapes them into C or U profiles through a series of roll stations, providing a fast, efficient method to produce lightweight, yet sturdy, steel structures.Read more

A Stud and Track Roll Forming Machine is an industrial device used to create steel studs and tracks – essential components in drywall, wall partition, and ceiling constructions. The machine takes metal strips and progressively shapes them into C or U profiles through a series of roll stations, providing a fast, efficient method to produce lightweight, yet sturdy, steel structures.Read more -

Metal Stud and Track Forming Machine for Light construction use. Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction workRead more

Metal Stud and Track Forming Machine for Light construction use. Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction workRead more -

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Read more

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Read more -

The metal stud roll forming machine applies strip steel as the raw material and undergoes continuous roll forming.Read more

The metal stud roll forming machine applies strip steel as the raw material and undergoes continuous roll forming.Read more -

stud and track systems are economical system to assemble frames for strong, compact, lightweight partitions. The metal stud partitioning is ideal for use in domestic and commercial situations, for heights up to 10m and a wide range of partition thicknesses.Read more

stud and track systems are economical system to assemble frames for strong, compact, lightweight partitions. The metal stud partitioning is ideal for use in domestic and commercial situations, for heights up to 10m and a wide range of partition thicknesses.Read more -

Cold roll forming machine, also known as a rollformer, is used to form high-strength steel components at room temperature and is often used to process long lengths of metal to produce a variety of metal products. The cross-sectional profile of a cold formed steel machine is typically tailored to the customer's specific needs. Also, the rollers can be adjusted to form a variety of different shapes and sizes. The process is very precise and can be used to create large quantities of parts quickly and accurately.Read more

Cold roll forming machine, also known as a rollformer, is used to form high-strength steel components at room temperature and is often used to process long lengths of metal to produce a variety of metal products. The cross-sectional profile of a cold formed steel machine is typically tailored to the customer's specific needs. Also, the rollers can be adjusted to form a variety of different shapes and sizes. The process is very precise and can be used to create large quantities of parts quickly and accurately.Read more -

A cut-to-length (CTL) machine is a versatile industrial equipment that revolutionizes the processRead more

A cut-to-length (CTL) machine is a versatile industrial equipment that revolutionizes the processRead more