Rincian Produk

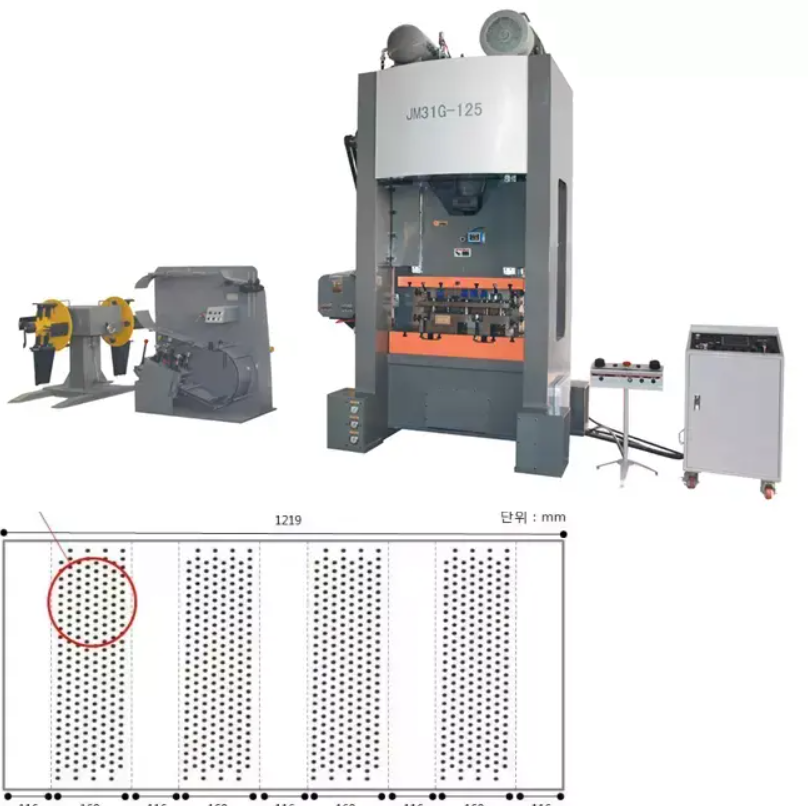

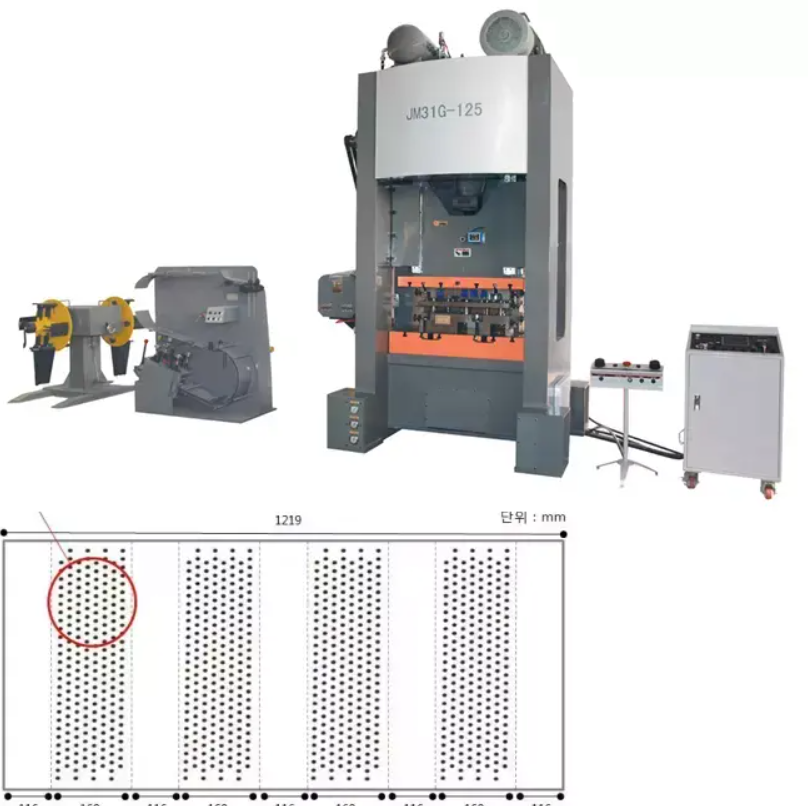

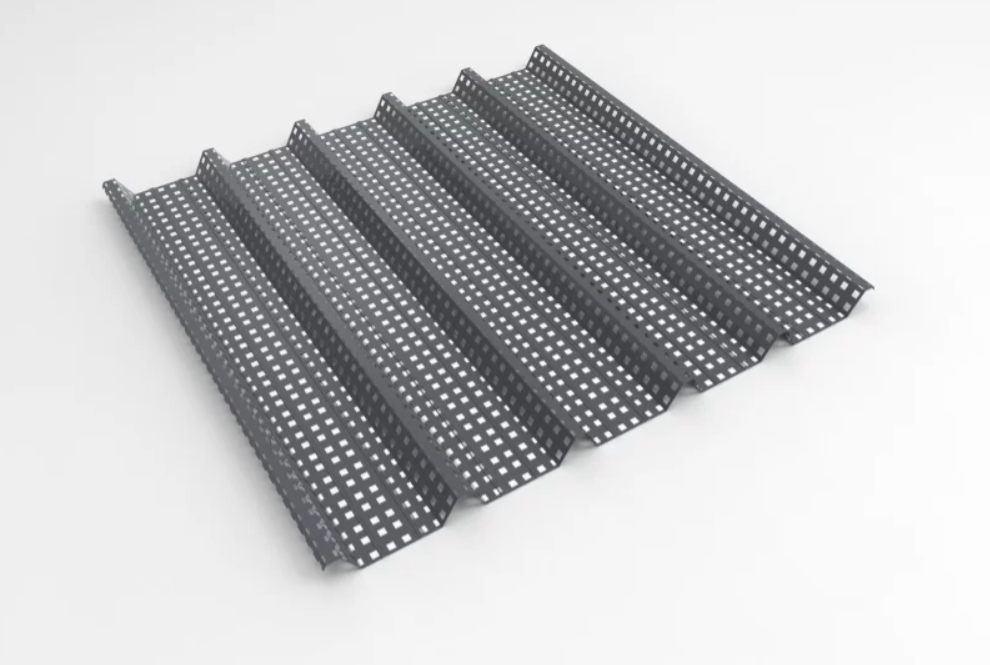

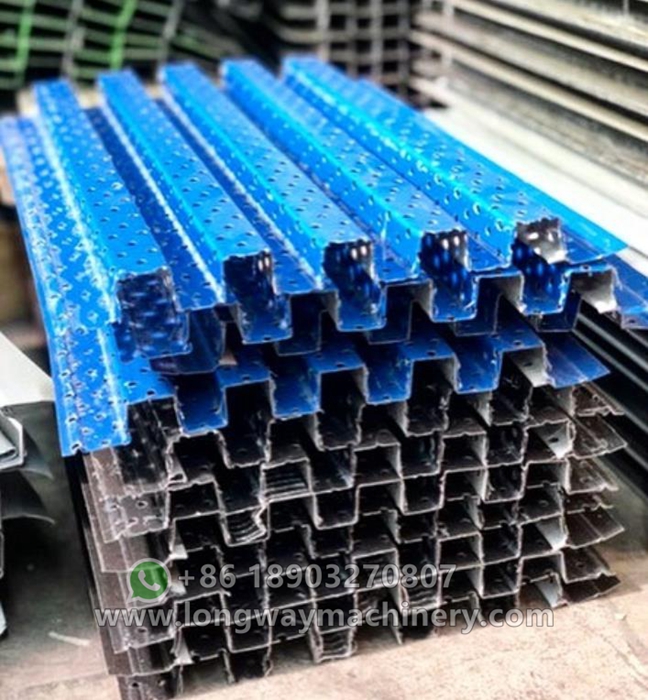

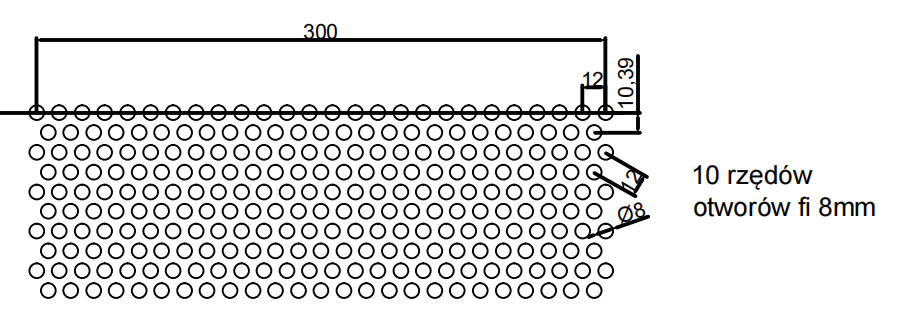

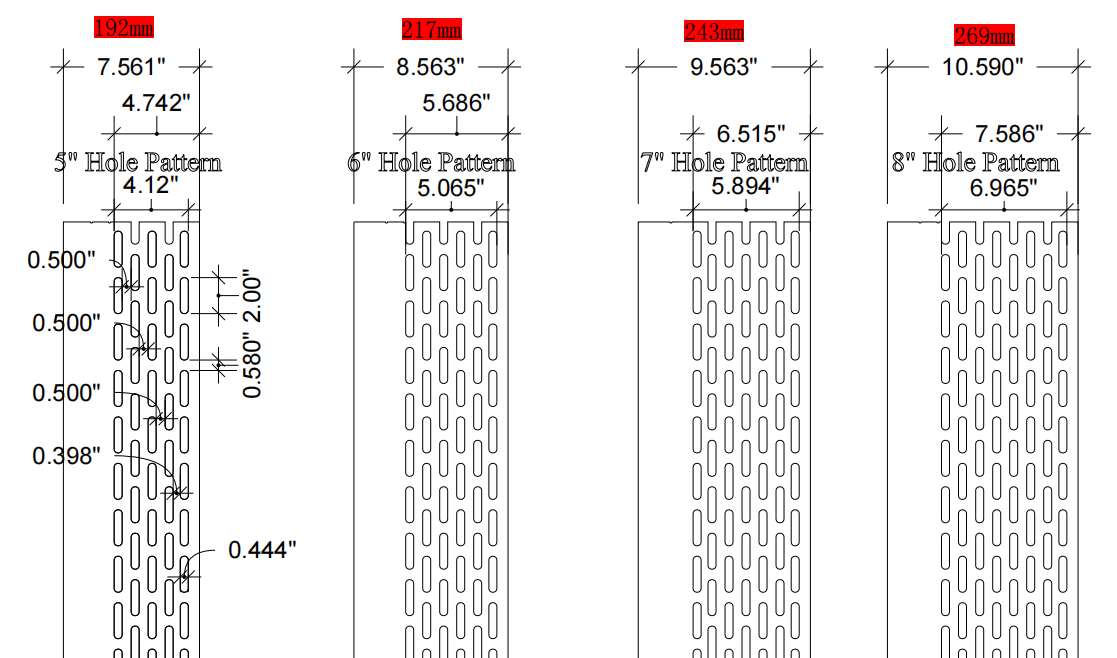

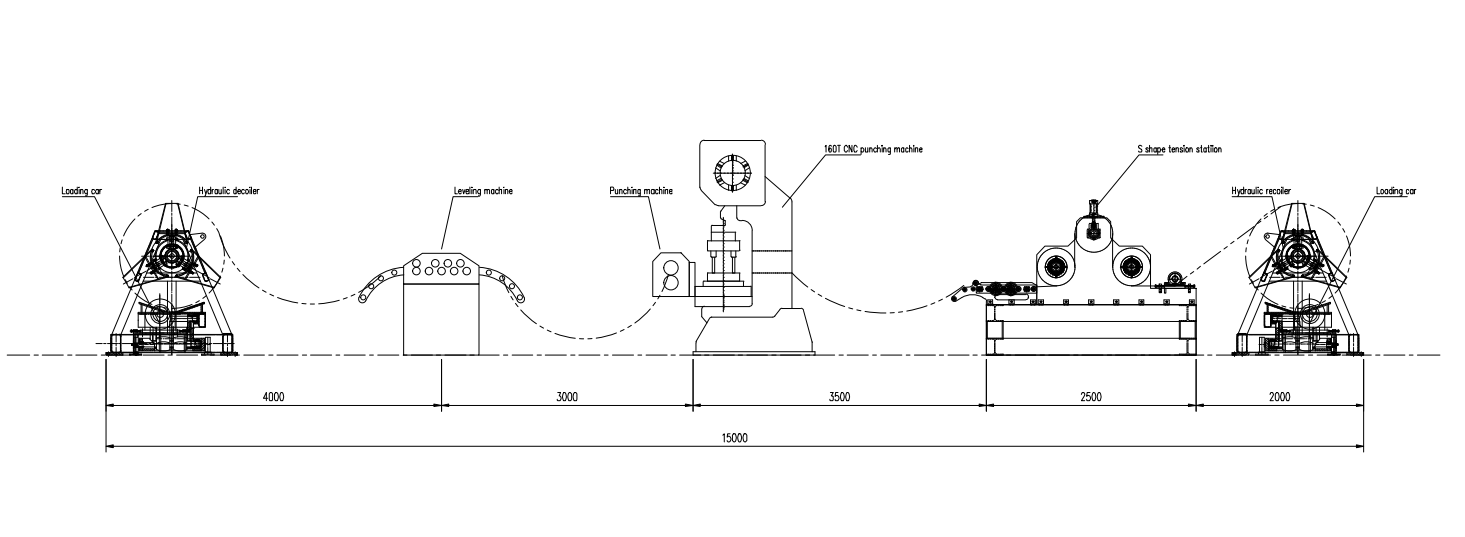

Metal sheet punching production line is designed to make the metal sheet, ALUMINIUM sheet punching and other material punching either from decoiler to recoiler or from decoiler to cut to length or only sheet punching machine. Meanwhile it also could be worked with the rolling forming machine. For example, some kind of profile needed to be punched and then do the rolling forming. So as to the punching line, it has many types combination. Here I will show you some types by some drawing profile for your reference:

Or punching could be like this:

Farameter Teknis

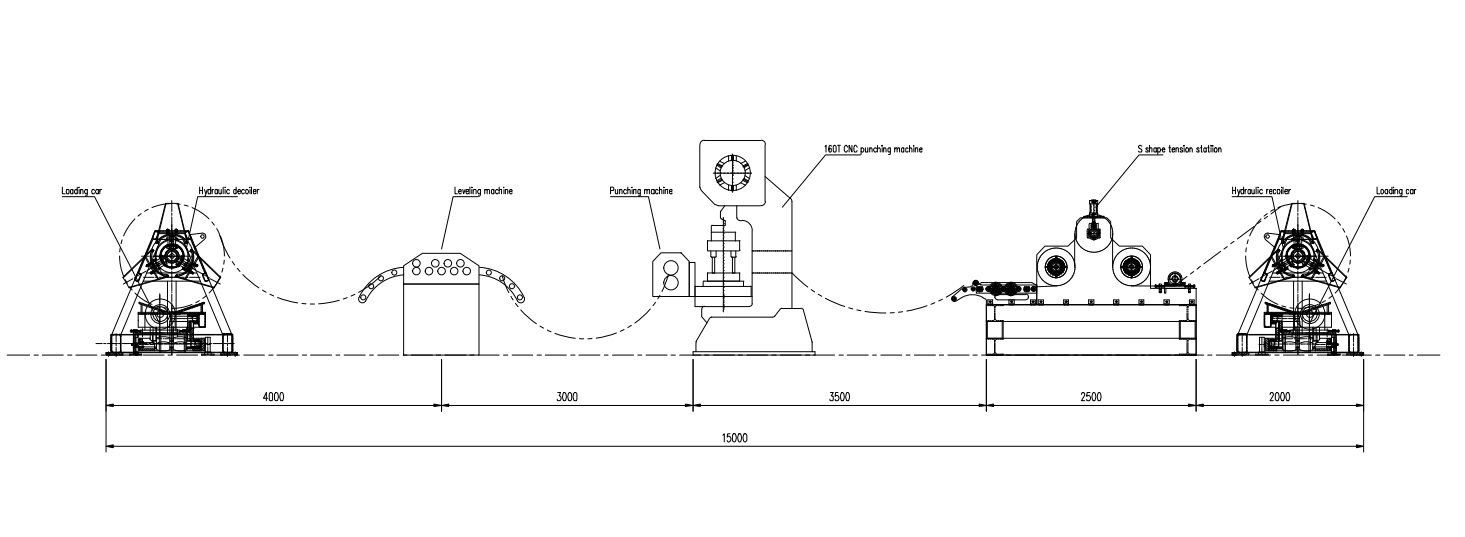

Metal sheet punching production line working flow:

Hydraulic decoiler -- Servo feeder -- Punching -- Damping device S rollers -- Recoiler (or could be cut to length)--> or main rolling forming machines Actually all elements are optional, like you can choose manual decoiler or electrical decoiler or hydraulic decoiler. As to the punching machine, you can choose to use the high speed punching or the normal speed punching machine and then the cost will be totally different.

|

Punching Machine Parameters |

||||

|

1.Supported Material |

PPGI,GI,AI |

Thickness:0.3-2.0mm Width:1000mm/1250mm(customized) |

||

|

2.Decoiler |

Hydraulic automatic decoiler |

Manual decoiler(will give you as free) |

||

|

3.Main Punching machine |

Pressure |

200 Ton |

||

|

Diameter of shaft |

80mm solid shaft |

|||

|

Bahan rol |

45# steel, hard chrome plated on the surface |

|||

|

Machine body frame |

baja 400 H |

|||

|

Drive |

Gearbox transmission |

|||

|

Dimension(L*W*H) |

15000*1800*1600(customize) |

|||

|

Berat |

18T |

|||

|

4.Cutter |

Automatic |

If you need tor cut to length |

||

|

5.Power |

Tenaga motor |

30 KW |

||

|

Kekuatan sistem hidrolik |

7.5KW |

|||

|

6.Voltage |

380V 50Hz 3Phase |

Customize |

||

|

7.Control system |

Electric Box |

Customized(famous brand) |

||

|

Language |

English(Support multiple languages) |

|||

|

PLC |

Automatic production of the whole machine. Can set batch, length, quantity, etc. |

|||

|

8.Forming Speed |

30-40m/min |

If you need to do the rolling forming |

||

Gambar Detail Mesin

Setiap komponen dapat dirancang sesuai kebutuhan khusus. Mesin roll forming panjang menyediakan OEM / ODM untuk semua pelanggan

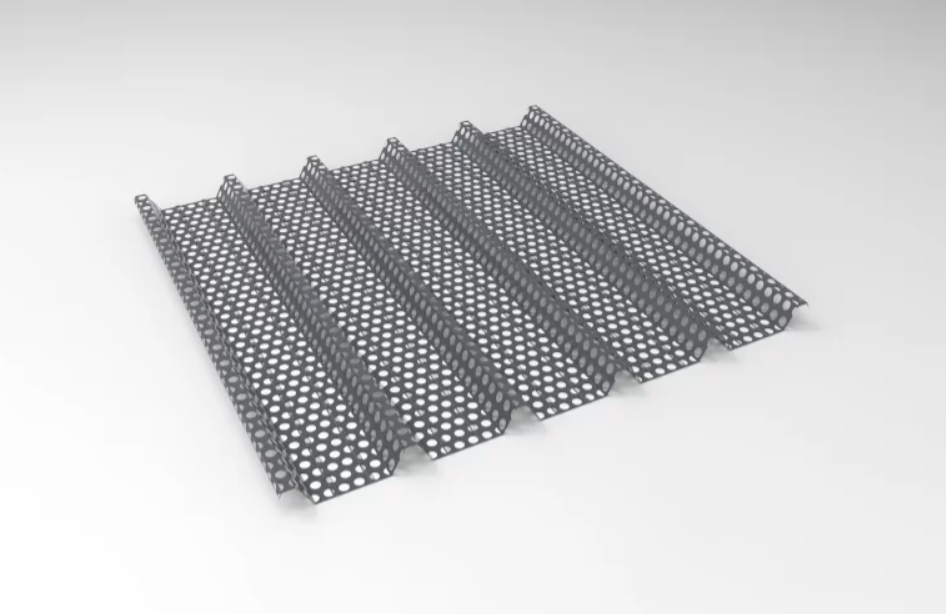

Aplikasi

Keunggulan lembaran logam Tr4 antara lain cantik, klasik, penampilan dan rasa anggun. t banyak digunakan di desa, hotel, pameran, desa liburan, konstruksi keluarga dan dekorasi luar ruangan.

Mesin Terkait

Pelanggan berharga JAUH

-

Chili

-

lran

-

Filipina

-

Afrika Selatan

Paket dan Pengiriman

1. Menyemprotkan minyak anti-korosif pada rol untuk mencegah oksidasi rol selama pengiriman

2.Packaging film isolasi seluruh mesin untuk mencegah oksidasi mesin selama pengiriman

3. Perencanaan ruang yang masuk akal untuk mengurangi biaya transportasi bagi pelanggan

4. Memperbaiki dengan baik untuk mencegah kerusakan mesin selama masa transit

Tampilan Pabrik