Product Details

Design Idea:

The heavy duty purlin macine can roll the thick material , Max thickness 3mm . For this machine we use the servo motor and Intelligent production system. Servo motors are well suited to precision to applications where accurate control of motor speed, position and/or torque is required.The first domestic self -developed intelligent fast input software -tedious input of liberation, improvement of work efficiency, one step ahead, one step by step (save about an hour of working hours per day)

Profile drawing for reference:

Technical Farameters

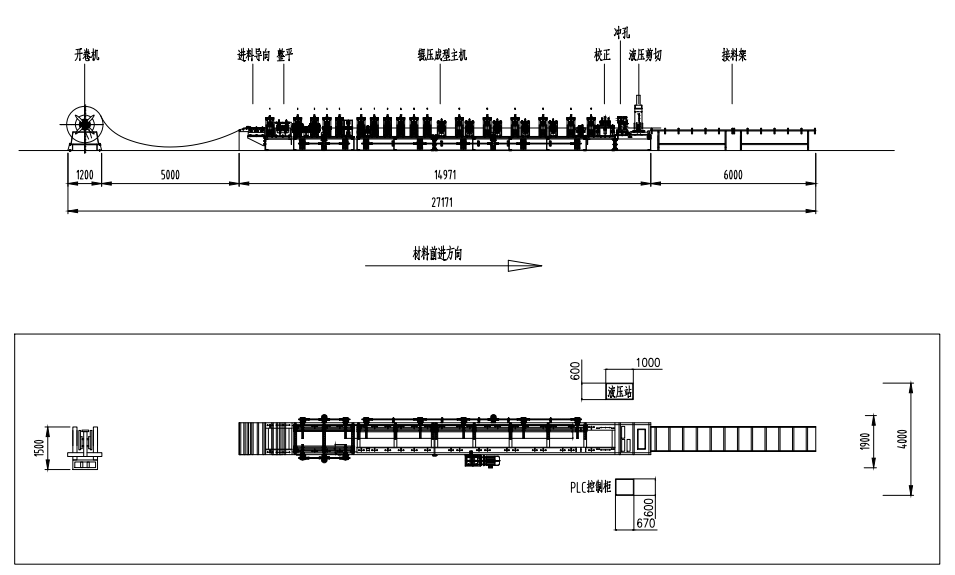

Processing Flow

|

Automatic Steel C U purlin Roll Forming Machine

|

|

|

Coil Material

|

Q215 Q235 Q345or other

|

|

Thickness

|

2.0-3.0mm

|

|

shaft material

|

45#steel

|

|

numbers of forming steps

|

12-16 stations

|

|

transmission

|

chain transmission

|

|

Frame

|

400 H steel

|

|

Forming speed

|

8-15m/min

|

|

main motor power

|

11-15kw

|

|

voltage

|

380V50HZ Three-phase or you need

|

|

cutting

|

Hydraulic cutting

|

|

Cutting power

|

5.5-7.5kw

|

|

blade material

|

Cr12 steel with quenched treated 60-62°c

|

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

C purlins, also known as Cee purlins, are in the shape of the letter C and provide structural support for beams required for walls and flooring. In addition to roofing, C purlins are often used for structural support in walls and as floor joists

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display