Product Details

Decoiler is an evitable part of roofing roll forming machine to hold and safely pay off the steel strip. A decoiler, also call uncoiler, unwinds steel coil, which can be feed into continuously running machineries such as roll former or automatic punches. Decoiler machine is suitable for all kinds of coil material feeding and the decoiler can work with straightener.

Technical Farameters

|

Manual Decoiler

|

||||

|

Capacity

|

3 tons,5 tons 8tons

|

|||

|

Coil inner diameter

|

450-550mm

|

|||

|

Feeding width

|

max 1220mm

|

|||

|

Structure

|

welded by the steel plates and profiled bar.

|

|||

|

Advantage

|

With handwheel for easy adjust for feeding different inner coil.

|

|||

|

More details

|

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine

|

|||

If your coil weight over 5 tons,the motor type decoiler or hydraulic type decoiler is more better for you to choose.You can also choose whether need the loading car or turnover device.

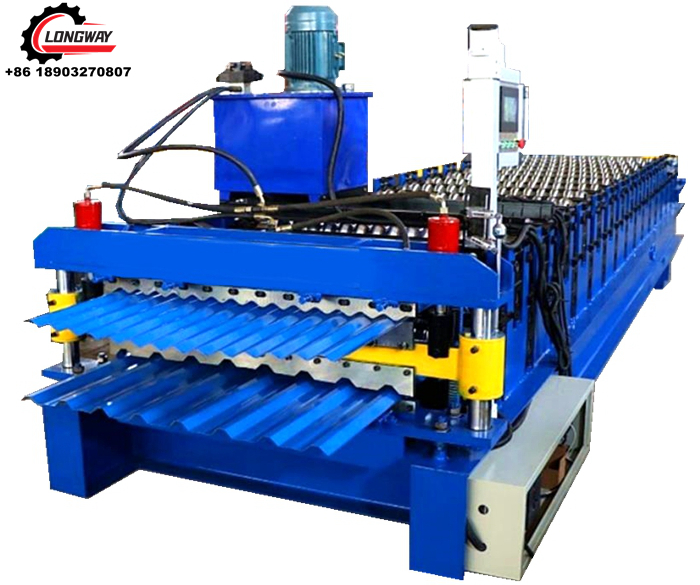

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

Applications

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display