Product Details

Metal coil slitting line steel slitting machine can cutting metal colour galvanized steel coil, carbon steel, hot rolled,cold rolled.

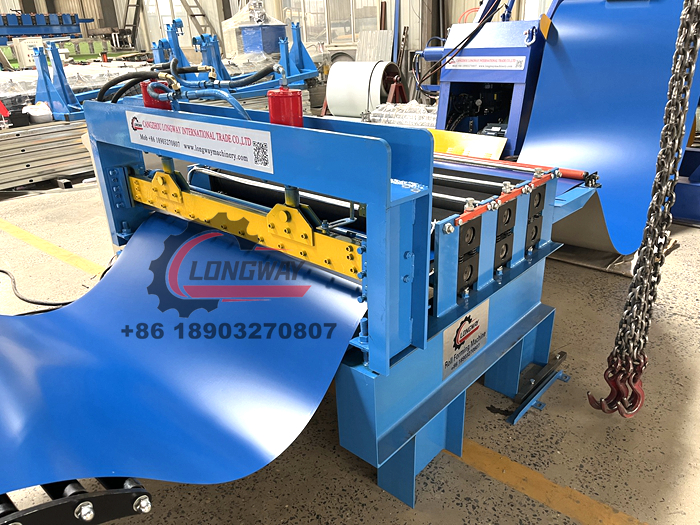

The whole production line include one set hydraulic decoiler with loading car, cutting& slitting machine, conveyor, stacker.

Total machine speed can reach 35 m/min, PLC control system control the running speed, cutting length, cutting quantity.

Decoiler and cutting& slitting machine use hydraulic working type, conveyor use electric type, stacker use pneumatic working type.

More technical parameters about machine, pls check below.

Technical Farameters

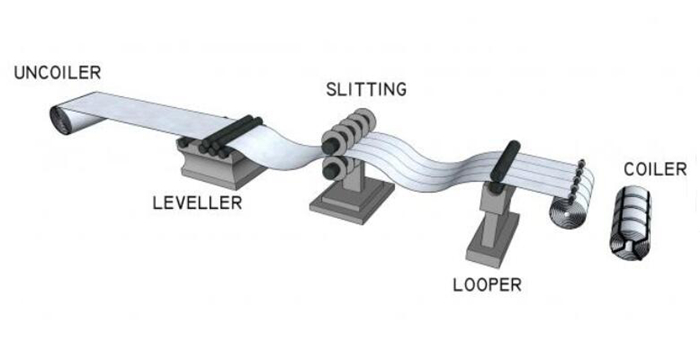

Work flow:

loading coil---uncoiling---leveling device---cutting sheet---convey table---automatic stacker

After you place order, we will give you a exact layout drawing according to your factory space for your convenience put the machine.

The machine is composed by the following elements:

Entry coil car, Hydraulic Decoiler, Hydraulic Press and pinch device, Side guide device1, Straightener, Hydraulic cutter, Roller table , Side guide device2, Slitter, Scrap winder, Tension stand , Recoielr, Exit coil car, Hydraulic system. Electrical system.

Now come to each elements of the machine:

Hydraulic decoiler

Width: 900—1250mm

Inner diameter: 508mmmm

Max out diameter: 1200mm

Max weight: 5 T - 15T

Decoiler speed: 0-20m/min

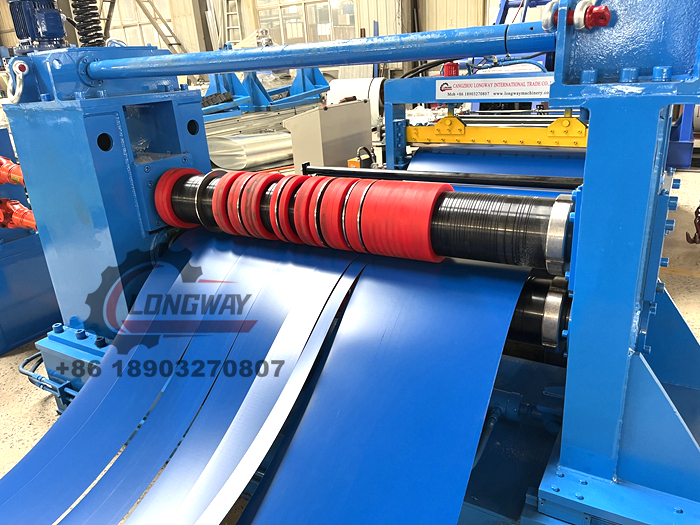

Slitting machine specifications:(Customized as coil thickness and speed)

Slitting speed : 0-30m/min

Drive motor : 18.5kw

Slitting shaft diamete: 110mm

Max slitting pieces: 10 pieces,as per requirements

Min slitting width: 50mm

Shearing blade material : 12CrMov

Pinching roller:2 couples

Recoiler specifications:

Max coil weight: 5 T - 15 T

Inner diameter: 508/610mm

Max out diameter: 1250mm

Recoiler motor: 11Kw

Hydraulic station power: 4Kw

Recoiler speed: 0-15m/min

Machine Detailed Pictures

Each components can be designed as custom require . Longway roll forming machine provides OEM/ODM for all customers

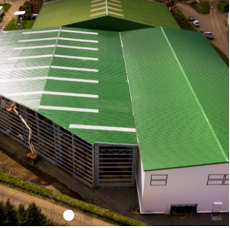

Applications

A slitting line produces longitudinal cuts in a master coil of steel to predetermined narrower widths. These smaller coils or “mults” are then sent to downstream operations such as metal stampers, tube producers or roll forming houses that will use the material in their final product.

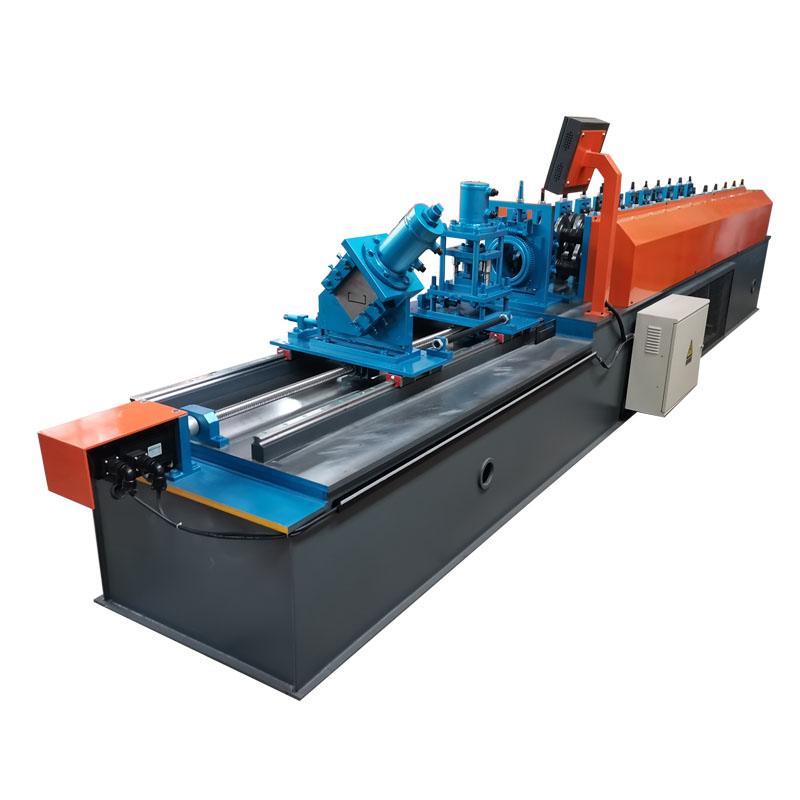

Related Machines

LONGWAY valuable customer

-

Chile

-

lran

-

Philippine

-

South Africa

Package and Delivery

1 .Spraying anti-corrosive oil on rollers to prevent rollers oxidation during shipping

2.Packaging isolation film whole machine to prevent machine oxidation during shipping

3.Reasonable space planning to reduce transportation costs for customers

4.Fixed well to prevent machine damage during transit period

Factory Display