Tag/standing seam mechanical seamer

-

Portable Standing seam roof panel roll forming machine

Portable Standing seam roof panel roll forming machine -

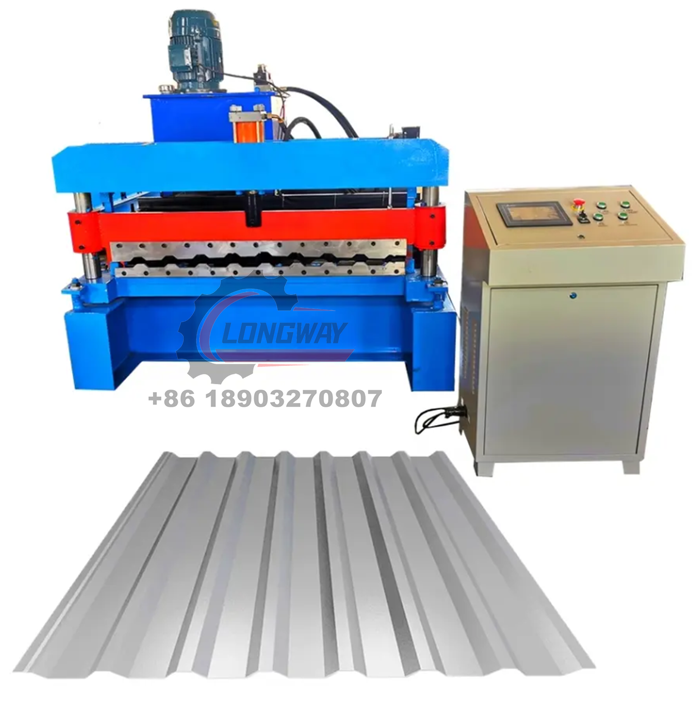

Maquina para panel micro acanalado/ondulado 762/1020

Maquina para panel micro acanalado/ondulado 762/1020 -

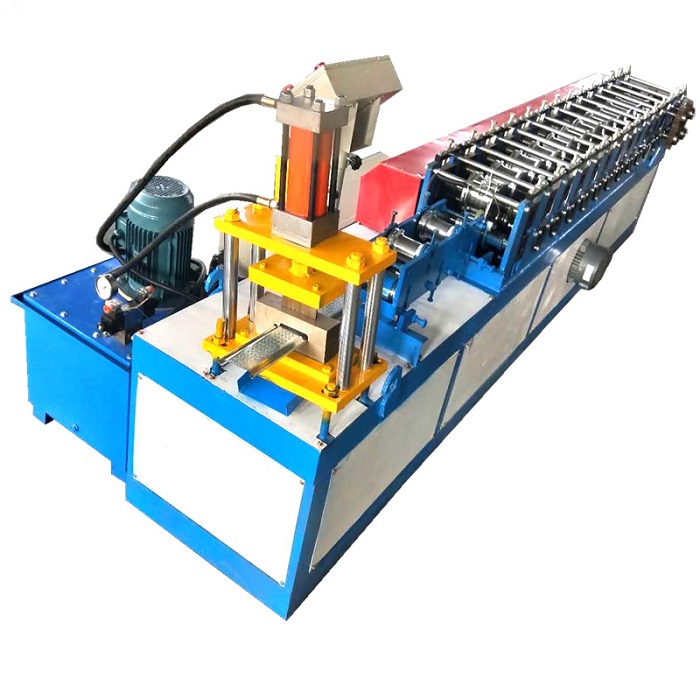

Steel Furring Channel roll forming machine

Steel Furring Channel roll forming machine -

Corrugated iron roofing sheet making machine with CE

Corrugated iron roofing sheet making machine with CE -

320 Cladding wall panel roll former

320 Cladding wall panel roll former -

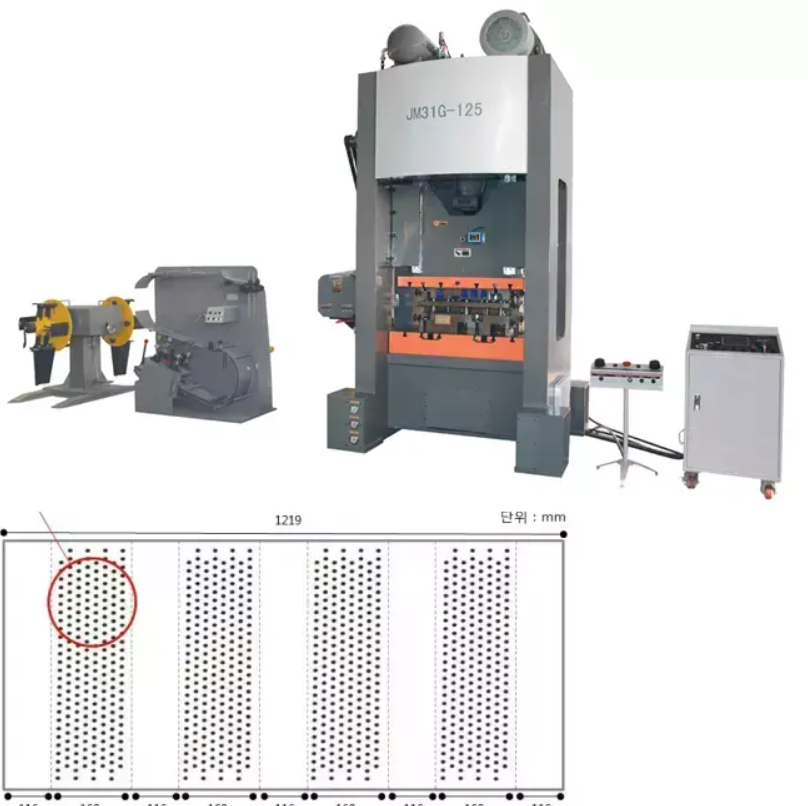

Metal sheet Perforados punching machine

Metal sheet Perforados punching machine -

3 Rib Trapezoid roof sheet making machine

3 Rib Trapezoid roof sheet making machine -

Maquina para zincalum 5v 6v

Maquina para zincalum 5v 6v -

Russia market C8 Roof profile forming machine

Russia market C8 Roof profile forming machine -

R101 Aluzinc Calamina Double Layer Roofing Machine

R101 Aluzinc Calamina Double Layer Roofing Machine

Produtct Title

standing seam mechanical seamer-

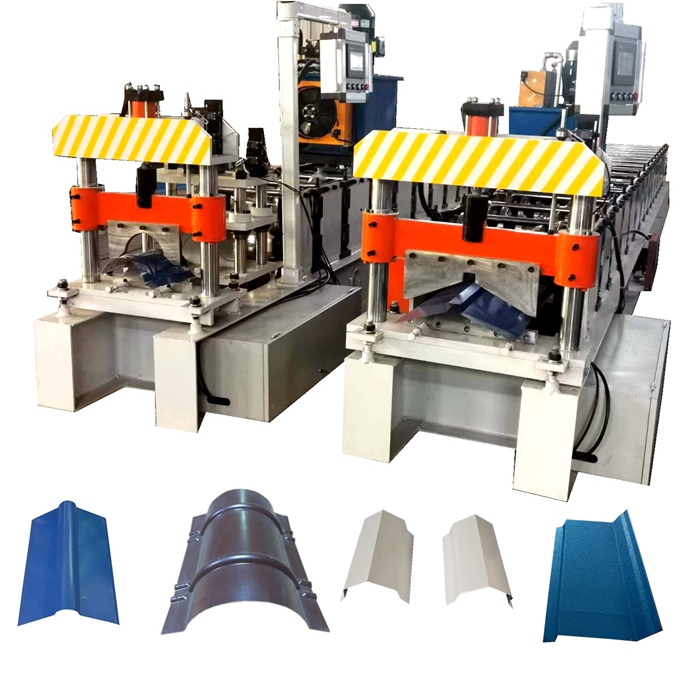

Metal Roof Ridge Cap Roll Forming Machine

-

Maquina para PANEL TINGLADO , TINGLADO panel forming machine

-

750 Trapezoidal Cladding wall panel forming machine

-

0.85mm Top hat Roof Batten Omega Roll Forming Machine

-

Steel C U purlin Roll Forming Machine

-

Maquina para soffit panel 200, soffit panel machine

-

Steel deck floor roll forming machine

-

Metal Roofing Tile Roll Forming Machine

-

R72 R101 Multi Ribs metal roof sheet forming machine

-

Glavanized steel Z purlin roll forming machine

-

Garage door rolling shutter machine

-

Aluminum 5 inch K gutter forming machine

-

Metal coil slitting line steel slitting machine

-

US R panel classic rib roof panel roll forming machine

Related News

-

2025-01-14A History of Laser Cutting-standing seam metal roof machineWhen you hear the word “laser,” what do you think of? For many people, lasers bring to mind images of Star Wars lightsabers and sci-fi movies. While lasers often feature in popular culture, many industries use laser technology as part of their manufacturing processes to cut and engrave materials.

-

2025-01-14Mobile Precision: Unleashing Efficiency with Portable Standing Seam Roof Panel Roll Forming MachinesIn the era of technological marvels, the "Portable Standing Seam Roof Panel Roll Forming Machine" emerges as a game-changer in the construction industry, bringing unparalleled efficiency and precision to the fabrication of roof panels.

-

2024-11-22metal roofing machine-Roof seamerCommonly, a roof seamer is developed as an afterthought. Since roof seamers are dependent on the metal roof system being used, their development was secondary to the roof panel. A roof seamer is a development that replaced a manual process and hand tools of the past. A hammer and small anvil were tools that were used for hemming and seaming roof panels together at the edge where they meet with the next roof panel in sequence.In 1976, a German immigrant and inventor, Ewald Stellrecht,[1] helped develop an early version of a metal roof panel portable roll forming machine in Exton, PA. From this a version of the roof seamer was also created. Since that time, great strides and innovations have been made in the development of roof seaming machines. Also, in the 1970s, Butler Manufacturing developed and released a proprietary roof system that featured the use of an electric roof seamer, dubbed the Roof Runner®, along with hand tools and an operating platform.[2] Many developments have been made since that time to make roof seamers lighter, faster, and more user-friendly. In 1989, Developmental Industries refocused the niche market by developing a line of roof seamers that were universal to many different panel manufacturers' products and were available to rent by the end-user.[3] Traditionally, purchasing a roof seamer meant that it would work with one specific roof panel, manufactured by a specific roof panel manufacturer. By opening up builders and installers to the option of renting, this allowed them to have the option of buying from different sources and greatly reducing their cost, making metal roofing a more accessible option for many that would not consider it before.

-

2024-02-22metal roofing machine-Standing Seam Curving MachineA standing seam curve machine is essential for shaping sheet metal in standing seam roofing systems. This system, commonly using materials like aluminum or steel, provides durable and weather-resistant roofing. The standing seam bender plays a key role, allowing precise bending of sheet metal by adjusting its rollers, roller dies, and bend angle settings.coil cut to length line manufacturers, curved standing seam, cut to length line manufacturers, electric seaming machine manufacturers, roller shutter machine manufacturers, standing seam curving machine manufacturers, standing seam machine manufacturers, standing seam metal roof machine, standing seam roof clips manufacturers, standing seam roof machine, steel coil slitting machine manufacturers

-

2024-02-22metal roofing machine-Standing Corrugated Roof Curving Sheet MachineFlatbed curving machines are mainly used in small-span engineering and rain shed. Normally install the keel frame under the colored steel sheet for this kind of project. Flat plate 840mm bending machine is used in the rain shed above the door is more common, generally like to choose horizontal type, corrugated sheet 820mm bending machine is commonly used in the bicycle shed, vertical type is more. KR series of bending machine is usually used in small warehouses, common is vertical. Bohai Company’s bending machine is in a leading position in the cold bending molding machine industry, welcome new and old customers to inquire.

-

2025-01-14Elevate Your Roofing Game: Exploring Standing Seam Roll FormersStanding seam roofs have become synonymous with modern architecture, offering sleek lines, durability, and energy efficiency.

-

2024-06-12Producers of standing seam roofing machineryStanding Seam Roofing Machine Manufacturers Pioneers in Modern Roofing SolutionsIn the world of co

-

2024-06-13Cheap standing seam rolling machine is efficient.The Versatile and Economical Solution The Cheap Standing Seam Rolling MachineIn the realm of metal

-

2024-06-13Manufacturer offering standing seam roofing machines for saleStanding Seam Machine for Sale Manufacturer's PerspectiveIn the realm of metal roofing and constru

-

2024-06-13Producers of portable standing seam roof roll forming machinesPortable Standing Seam Roll Former Manufacturers Revolutionizing the Roofing IndustryIn the dynami

-

2024-06-21Here are 10 short phrases with approximately 10 words each that are related to the custom standing seam roof machine 1. Custom standing seam roofing system 2. Automated standing seam roof installatioThe Custom Standing Seam Roof Machine Revolutionizing Roofing ConstructionIn the realm of roofing

-

2024-06-14Specialized company for roof seam welding machinesRoof Seamer Machine Companies Pioneers in Modern Roofing SolutionsIn the dynamic world of construc

-

2024-06-15Seam crimping machine.Standing Seam Crimping Machine Revolutionizing Roofing IndustryThe Standing Seam Crimping Machine

-

2024-06-21Here are 10 similar short phrases to standing seam metal roofing machine companies 1. Metal roof machinery suppliers 2. Standing seam roofing equipment manufacturers 3. Roofing sheet machinery companStanding Seam Metal Roofing Machines Revolutionizing the IndustryIn the realm of construction and

-

2024-06-20Standing seam roofing machine for metal panel shapingUnderstanding the Standing Seam Profiling Machine A Technological Marvel in Metal RoofingIn the re

-

2024-06-24Portable Standing Seam Roofing Machine ManufacturersPortable Standing Seam Roofing Machine for Sale A Comprehensive GuideIn the realm of construction

-

2024-06-26Expert Manufacturer of Standing Seam Roofing MachinesStanding Seam Roof Machine Companies Pioneers in Architectural InnovationIn the realm of roofing t

-

2024-06-26Top Manufacturers of Standing Seam Roofing Machines A Comprehensive OverviewStanding Seam Roofing Machine Manufacturers Pioneers in Architectural InnovationIn the realm of co

-

2024-07-02Standing Seam Roof Panel Rolling Machine Crafting Superior Roofing SolutionsUnderstanding the Standing Seam Roof Panel Roll Forming MachineIn the realm of construction and me

-

2024-07-03Purchase High-Quality Standing Seam Roofing Machine from Top ManufacturerStanding Seam Roof Machine for Sale A Key to Unparalleled Roofing SolutionsIn today's rapidly evol

Related Search

- standing seam metal roof machine

- standing seam metal roofing machine

- standing seam roof machine

- portable standing seam roofing machine

- standing seam roof panel machine

- standing seam machine

- standing seam roll former

- standing seam machine for sale

- standing seam roll former for sale

- standing seam panel machine

- standing seam metal machine

- standing seam roll forming machine

- standing seam metal roof machine price

- standing seam metal roof machine for sale

- standing seam machine price

- roof seamer machine

- standing seam forming machine

- portable standing seam machine

- double lock standing seam machine

- standing seam roof machine for sale

- standing seam crimping machine

- standing seam panel machine for sale

- portable standing seam machine for sale

- standing seam mechanical seamer

- standing seam profiling machine

- portable standing seam roll forming machine

- snap lock standing seam roll forming machine

- standing seam metal roof roll former

- standing seam roll forming machines for sale

- standing seam curving machine