Jun . 20, 2024 03:08

Back to list

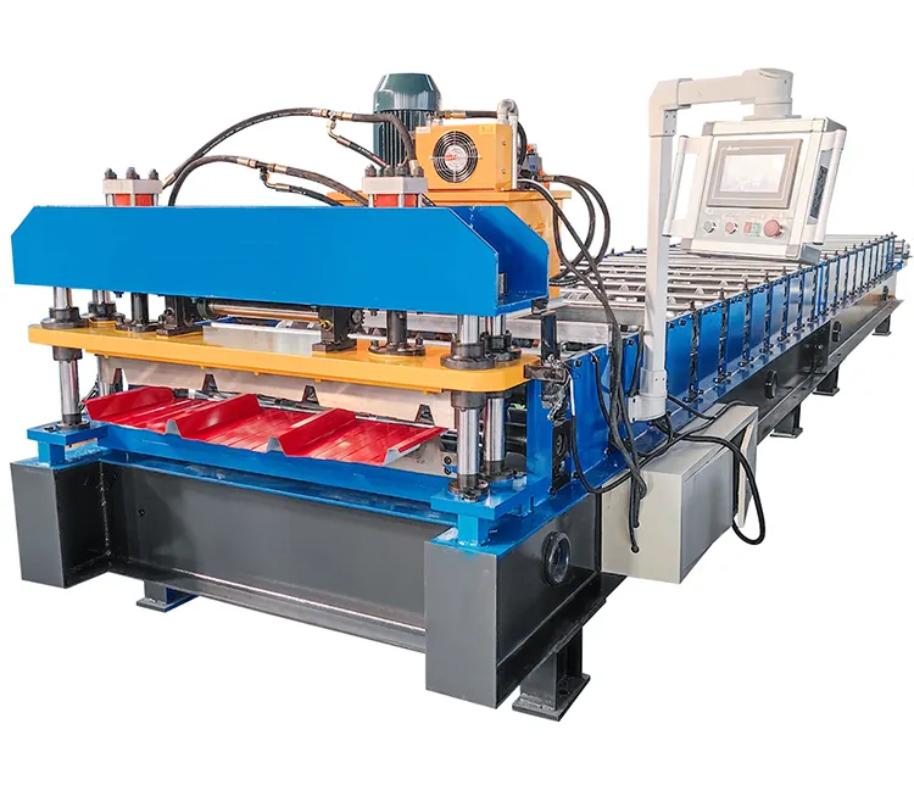

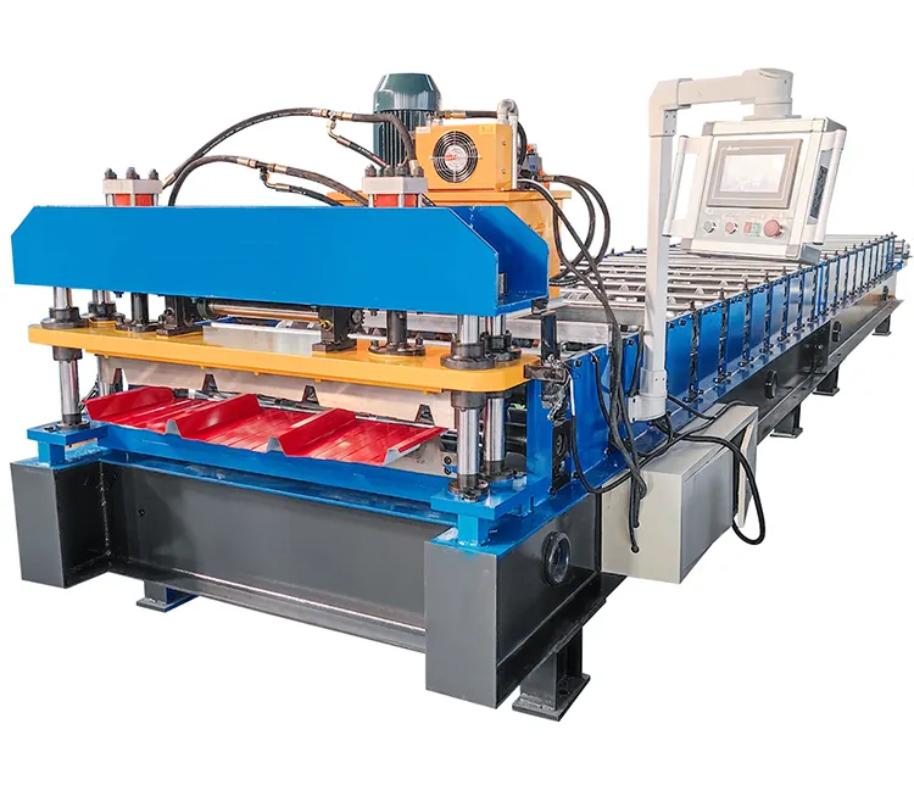

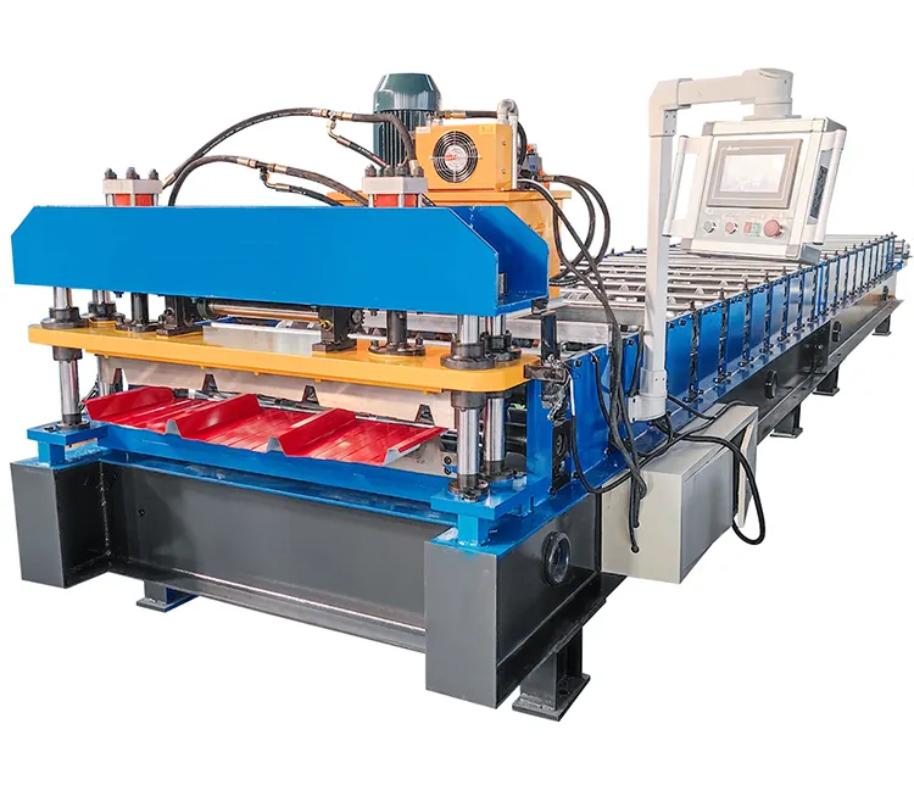

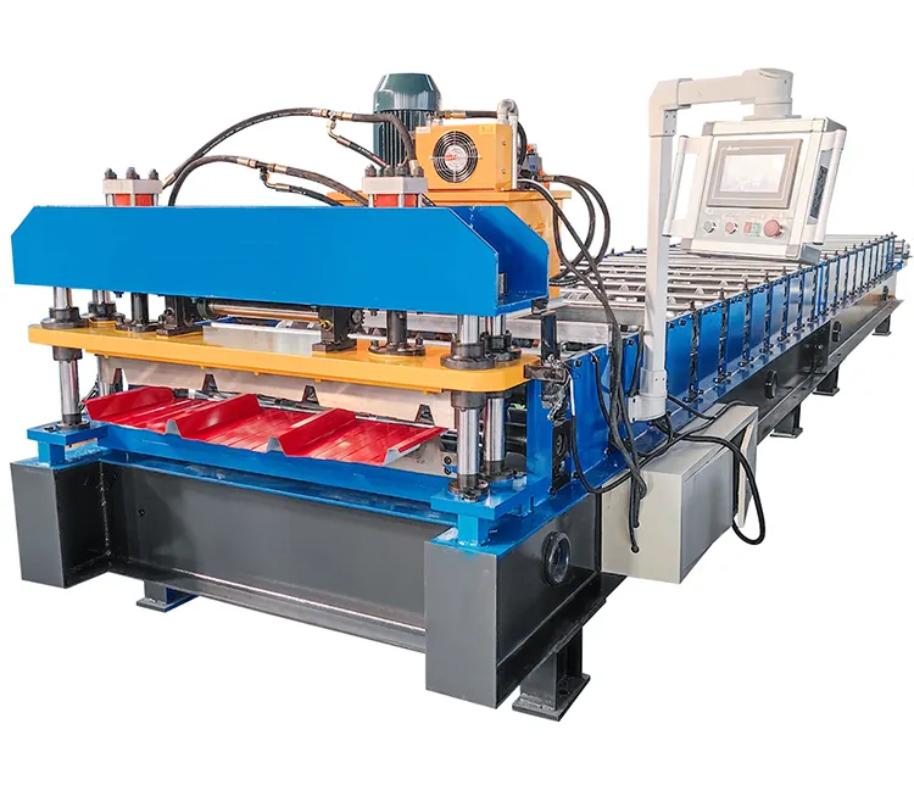

Standing seam roofing machine for metal panel shaping

Understanding the Standing Seam Profiling Machine A Technological Marvel in Metal Roofing

In the realm of metal roofing fabrication, a Standing Seam Profiling Machine holds a significant position due to its precision and efficiency. This innovative machinery is specifically designed to create standing seam profiles, a popular choice for architectural designs due to their aesthetic appeal and robust functionality.

Standing seam profiling machines are primarily used to form interlocking metal panels with raised seams, a process known as standing seam roofing. The term 'standing seam' refers to the vertical ribs that run from the roof's eave to its ridge, standing upright rather than lying flat. These seams not only provide a sleek, modern appearance but also ensure excellent waterproofing and durability.

The machine operates by feeding metal sheets through a series of rollers that shape and fold the metal into the desired standing seam profile. It can handle a variety of materials, including aluminum, steel, and copper, making it versatile for different construction projects. The process typically involves sheet feeding, seam formation, and locking, all executed with incredible accuracy and speed.

One of the key advantages of the standing seam profiling machine is its ability to produce consistent, high-quality results. The machine's precision engineering ensures that each seam is uniform, thereby enhancing the structural integrity and weather resistance of the roof. Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency

Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency standing seam profiling machine.

The standing seam profiling machine also offers flexibility in design. It can produce various seam profiles, such as snap-lock, mechanical lock, or double-lock, depending on the project's specific requirements. This adaptability allows architects and builders to achieve the desired aesthetic while maintaining optimal performance.

Furthermore, these machines often incorporate advanced technologies like computer numerical control (CNC), which enables the operator to program and customize the profiling process according to precise measurements and specifications. This integration of technology not only enhances productivity but also minimizes errors and waste.

In conclusion, the standing seam profiling machine is a testament to the fusion of engineering excellence and technological innovation in the construction industry. Its role in the manufacturing of standing seam metal roofs cannot be overstated, as it brings together efficiency, precision, and versatility in one streamlined operation. As the demand for sustainable and visually appealing roofing solutions grows, the standing seam profiling machine will continue to play a pivotal role, shaping the skyline with its precision-formed seams.

standing seam profiling machine.

The standing seam profiling machine also offers flexibility in design. It can produce various seam profiles, such as snap-lock, mechanical lock, or double-lock, depending on the project's specific requirements. This adaptability allows architects and builders to achieve the desired aesthetic while maintaining optimal performance.

Furthermore, these machines often incorporate advanced technologies like computer numerical control (CNC), which enables the operator to program and customize the profiling process according to precise measurements and specifications. This integration of technology not only enhances productivity but also minimizes errors and waste.

In conclusion, the standing seam profiling machine is a testament to the fusion of engineering excellence and technological innovation in the construction industry. Its role in the manufacturing of standing seam metal roofs cannot be overstated, as it brings together efficiency, precision, and versatility in one streamlined operation. As the demand for sustainable and visually appealing roofing solutions grows, the standing seam profiling machine will continue to play a pivotal role, shaping the skyline with its precision-formed seams.

Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency

Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency Moreover, the automated nature of the process significantly reduces labor costs and increases production efficiency standing seam profiling machine.

The standing seam profiling machine also offers flexibility in design. It can produce various seam profiles, such as snap-lock, mechanical lock, or double-lock, depending on the project's specific requirements. This adaptability allows architects and builders to achieve the desired aesthetic while maintaining optimal performance.

Furthermore, these machines often incorporate advanced technologies like computer numerical control (CNC), which enables the operator to program and customize the profiling process according to precise measurements and specifications. This integration of technology not only enhances productivity but also minimizes errors and waste.

In conclusion, the standing seam profiling machine is a testament to the fusion of engineering excellence and technological innovation in the construction industry. Its role in the manufacturing of standing seam metal roofs cannot be overstated, as it brings together efficiency, precision, and versatility in one streamlined operation. As the demand for sustainable and visually appealing roofing solutions grows, the standing seam profiling machine will continue to play a pivotal role, shaping the skyline with its precision-formed seams.

standing seam profiling machine.

The standing seam profiling machine also offers flexibility in design. It can produce various seam profiles, such as snap-lock, mechanical lock, or double-lock, depending on the project's specific requirements. This adaptability allows architects and builders to achieve the desired aesthetic while maintaining optimal performance.

Furthermore, these machines often incorporate advanced technologies like computer numerical control (CNC), which enables the operator to program and customize the profiling process according to precise measurements and specifications. This integration of technology not only enhances productivity but also minimizes errors and waste.

In conclusion, the standing seam profiling machine is a testament to the fusion of engineering excellence and technological innovation in the construction industry. Its role in the manufacturing of standing seam metal roofs cannot be overstated, as it brings together efficiency, precision, and versatility in one streamlined operation. As the demand for sustainable and visually appealing roofing solutions grows, the standing seam profiling machine will continue to play a pivotal role, shaping the skyline with its precision-formed seams. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products