Tag/cut to lenght line factory

-

1mm Simple steel coil cut to length machine

1mm Simple steel coil cut to length machine -

Metal coil slitting line steel slitting machine

Metal coil slitting line steel slitting machine -

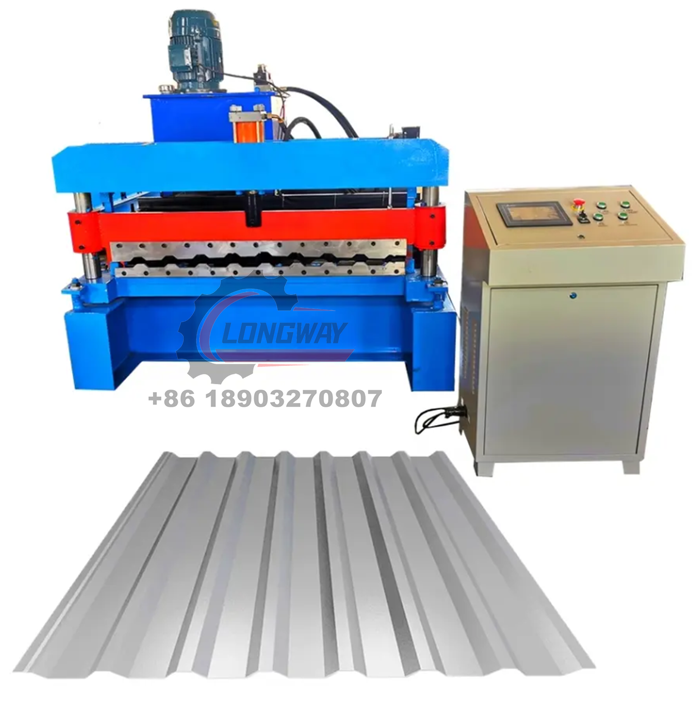

988 Corrugated roofing sheet forming machine

988 Corrugated roofing sheet forming machine -

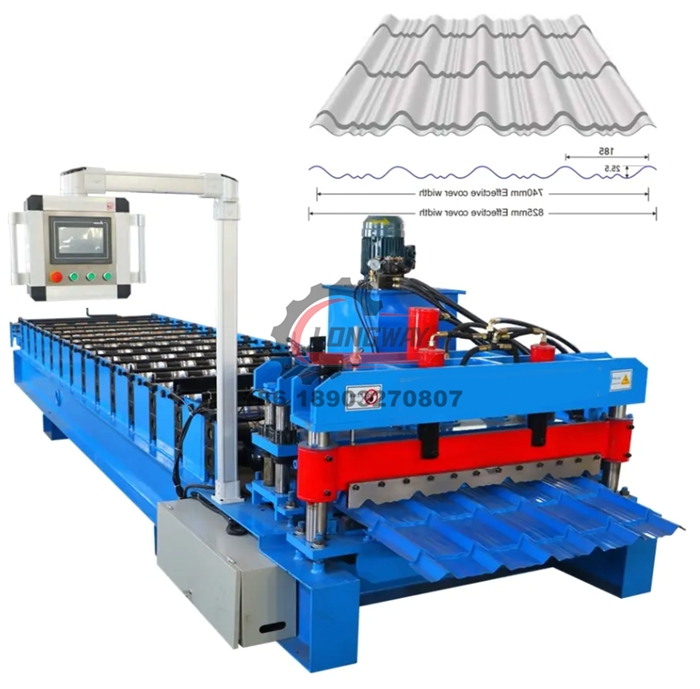

T18 T35 Two in One Metal Roofing Machine

T18 T35 Two in One Metal Roofing Machine -

Maquina para fabricar paneles de techo 910 PV6

Maquina para fabricar paneles de techo 910 PV6 -

Aluminum 5 inch K gutter forming machine

Aluminum 5 inch K gutter forming machine -

Peru Market Bamboo Aluzinc Roof Tile Making Machine

Peru Market Bamboo Aluzinc Roof Tile Making Machine -

Metal Roofing Tile Roll Forming Machine

Metal Roofing Tile Roll Forming Machine -

18 Corrugated Steel Roofing Sheet Making Machine

18 Corrugated Steel Roofing Sheet Making Machine -

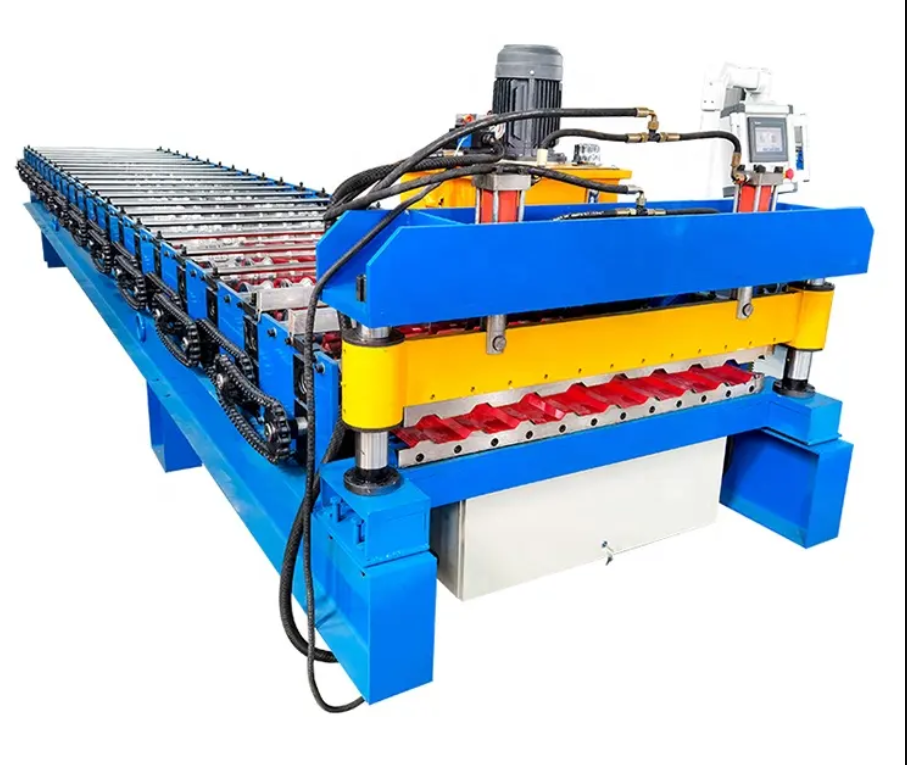

Aluzinc Tr4 Tr5 Double Deck Roof Forming Machine

Aluzinc Tr4 Tr5 Double Deck Roof Forming Machine

Produtct Title

cut to lenght line factory-

R72 R101 Multi Ribs metal roof sheet forming machine

-

Q Tile Metal Roofing Step Tile Forming Machine

-

Corrugated iron roofing sheet making machine with CE

-

Tr20 Tr40 roof panel forming machine

-

T18 C18 Metal roofing machine Roof sheet forming machine

-

750 Trapezoidal Cladding wall panel forming machine

-

Ceiling Channel Roll Forming Machine

-

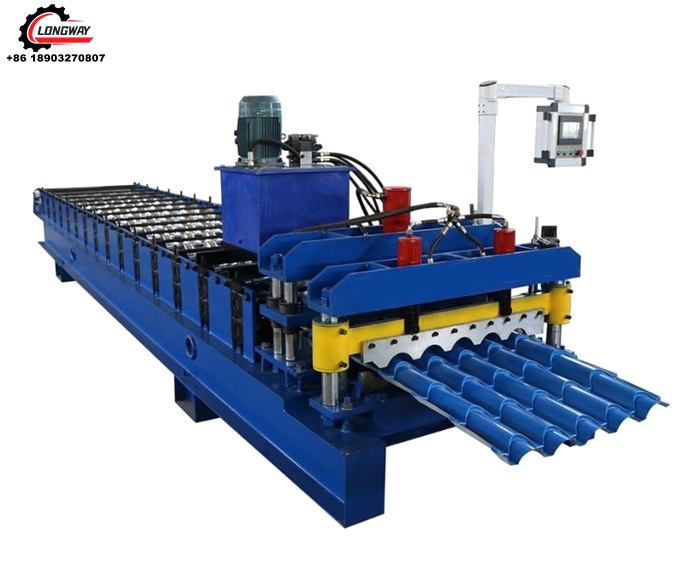

Two deck roll forming machine for micro calamina ondulada

-

Hydraulic Decoiler With Loading Car Automatic Uncoiler

-

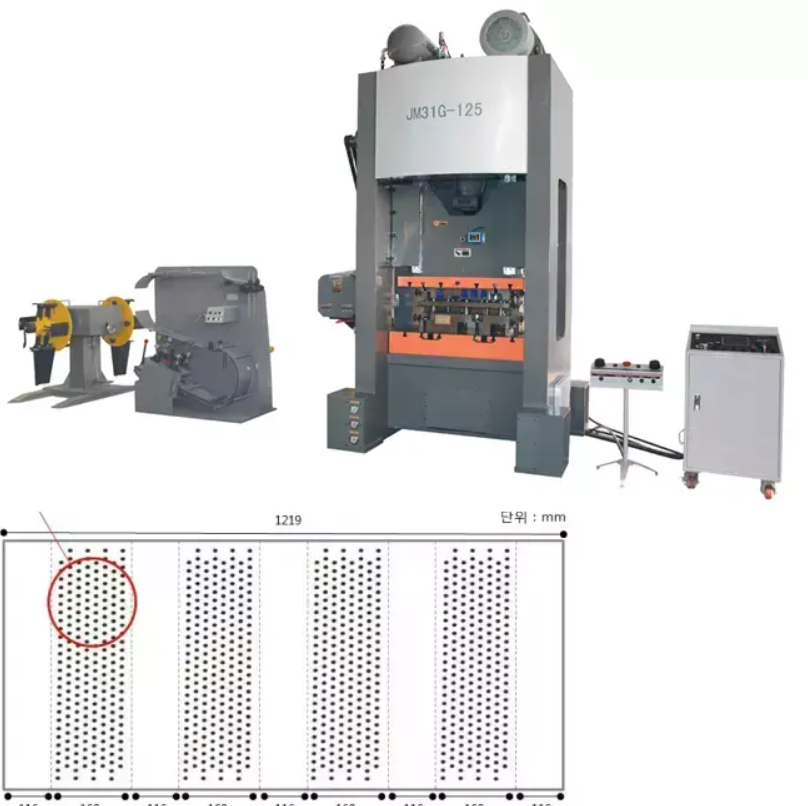

Metal sheet Perforados punching machine

-

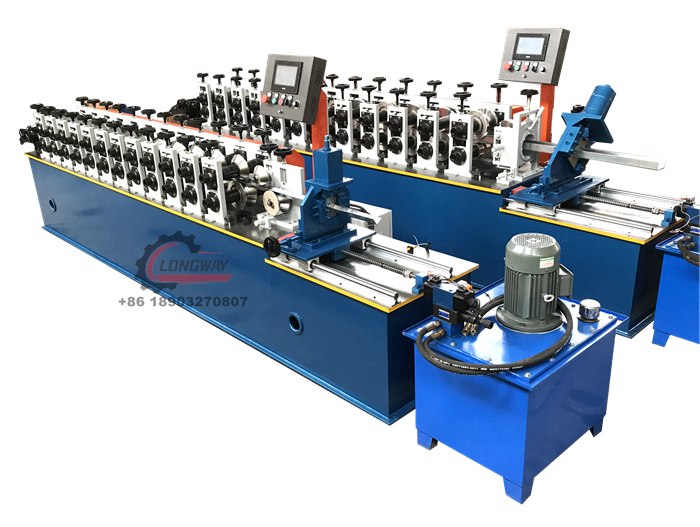

Drywall Metalcon perfil C U channel forming machine

-

Drywall Steel L Angle Bar forming machine

-

Drywall Stud and Track Roll Forming Machine

-

R101 Aluzinc Calamina Double Layer Roofing Machine

Related News

-

2025-01-14Arrange shipment for Steel coil slitting line to ChileSteel coil slitting line often works for big coil material , whole line can cut big coils into small coils with rewinder function . Longway Roll Forming Machine ship whole slitting line today .

-

2025-01-14Accessories Flying Cut-offs Punch Units-cut to length machineA production type of roll form system will want to be able to continuously produce parts. All parts must be limited in length after they are shaped in the roll form equipment and some parts need strategic holes and slots punched.

-

2025-01-14Understanding Roll Forming Machine Parts and Their Functions-cut to length machineA roll forming machine or sheet metal roll forming machine is a piece of equipment used in the manufacturing industry to shape metal sheets or coils into a wanted shape or profile.Roll forming is a continuous process of feeding metal, whether it’s finished, coiled, flat, or otherwise, through a series of rollers, each set of rollers gradually bending the metal into the desired shape.

-

2025-01-14How Does a Roll Forming Machine Work-cut to length machineoll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.

-

2025-01-14Pre-Cut or Post-Cut Roll Forming Lines? Which is better?Roll forming lines can be configured in two ways to create length-specific formed parts. One method is pre-cutting, which involves cutting the steel coil before it enters the roll former. The other method is post-cutting, where a profiled shear cuts the sheet after it is formed. Both methods have their advantages, and the choice depends on specific factors related to your production requirements.

-

2025-01-14Advancements in Cutting Machinery: Enhancing Precision and Efficiency-cut to length machineCutting to Desired Lengths – Exploring the Versatile World of Cutting MachineryCutting machinery has revolutionized industries by providing solutions to tailor materials to specific lengths. This article delves into the machine designed for cutting materials to desired lengths, discussing its applications across various industries, including metal and wood processing. Highlighting its advantages such as efficiency, precision, and reliability, we explore how this machinery meets diverse needs.

-

2025-01-14Custom Roll Forming Services-cut to length machineRoll forming—also stylized as roll-forming or roll forming—is a metalworking process that employs a series of rolls to continuously bend a coil of sheet metal until it has the desired profile. The rolls come in sets that are mounted on consecutive stands to facilitate the forming operation. As the strip—typically made of coiled steel—runs through the sets of rolls, each set incrementally produces a bend in the material.

-

2025-01-14ROLL FORM TOOLING SUPPLIERS: COST SAVINGS DOWN THE LINE-roll forming machineTooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-prohibitive altogether. The up-front price tag tends to blind them to literal down-the-line savings.That’s right -- if your project fits, a roll form manufacturer can actually optimize your spending and get your parts out the door sooner and for less money per part.

-

2025-01-14Roll Forming Line Operation and Setup-roll form machineWhile there is no catch-all roll forming solution for every business, there are some elements of the roll forming process that ring true across operations. Regardless of your size, your industry, and even your end product, roll forming machinery is designed to add efficiency, quality, and ultimately profits to your metal forming processes. The requirements necessary to maintain and operate a roll forming system can be loosely defined depending on your shop's specific needs. In this post, we'll discuss some of the variables that determine roll forming line operation and setup across metal forming industries.

-

2024-01-11A Guide on How to Cut Metal RoofingChoosing a metal roof for your Florida house is a wise long-term investment. Installing one might also put your metalworking talents to the test if you prefer do-it-yourself projects.A metal roof consists of various trims and many large sheets or panels cut to size. Before delving into it, you must learn how to cut metal roofing as accurately as possible to minimize wastage and costs. Below is a guide to get you started.

-

2024-11-22cut to length machine-COIL HANDLING AND SLIT & CUT TO LENGTHWith a well equipped cut-to-length in your production facility you will no longer need to cut strips in guillotine shears.Do you sell sheets or do you want to recoil material in smaller coils? We have the right solution for you!Rational coil handling cuts your lead times, frees up production space and reduces tied up capital in stocks.CIDAN Machinery manufactures slit and cut-to-length lines that can be programed and operated by skilled and non-skilled users alike. Our cut-to-length machines are all-in-one units built to withstand high-level production over the course of time while taking up as little space as possible.

-

2024-11-22cut to length machine-Cut to Length System | Wire Cutting Machinethat is compact, easy to operate, and cost effective.These cut to length machines are designed to provide versatility. Any combination of these points makes the systems easy to justify.Extremely wide range of materials—A quick tooling changeover enables every unit to accommodate a range of materials.Multiple diameters—Each of our cutoff systems has a wide capacity range that can run many different size diameters, each up to .375”.Variable cut lengths—Our pneumatic systems can cut lengths up to 300 feet, while our servo systems are only limited by the amount of material on the coil or spool making these the most versatile wire cutting machines on the market.Different Shapes? No Problem—The use of diameter- or shape-specific tooling allows an operator to quickly change from one shape material to another.Custom Forming-Wire Cutting Equipment tooling to leave wire with formed ends including angle cuts, flattened ends, etc.

-

2024-11-22cut to length machine-What is the slitting machine divided into several types1. Purpose: Suitable for longitudinal shearing of metal strips, and rewinding the slitted narrow strips into rolls.2. Advantages: convenient operation, high cutting quality, high material utilization, and stepless speed regulation of the cutting speed.3. Structure: It consists of unwinding (unwinding), leading material positioning, slitting and slitting, coiling (rewinding), etc.4. Applicable materials: tinplate, silicon steel sheet, aluminum strip, copper, stainless steel sheet, galvanized sheet.5. Applicable industries: transformers, motors, home appliances, automobiles, building materials, packaging industries, etc.Slitting machines are divided into parallel blade shears and oblique blade shears. Parallel blade shears. The two blades of this shearing machine are parallel to each other. It is usually used for transverse shearing of blooms (square, slab) and other square and rectangular section billets, so it is also called billet shearing machine. This type of shearing machine sometimes also uses two forming blades to cold cut rolled parts (such as round tube blanks and small round steel, etc.), and the shape of the blade is adapted to the cross-sectional shape of the cut-and-rolled part. Oblique blade shearing machine. The two blades of this shearing machine, the upper blade is inclined, the lower blade is horizontal, and they are at a certain angle to each other. The inclination of the upper blade is 1°~6°. This kind of shearing machine is often used for cold shearing and hot shearing of steel plates, strip steels, thin slabs and welded pipe billets. Sometimes it is also used to cut small steel into bundles.

-

2024-11-22metal roofing machine-Cut To Length LineBLUE SKY Cut To Length Lines (CTL) Are Designed With The Latest Standards Of Technology And Completely Made In Our Factory. Our Cut To Length Lines (CTL) Can Be Used For Processing Hot And Cold-Rolled Galvanized, Pre-Painted And Stainless-Steel Coils, As Well As Nonferrous Materials – Aluminium, Copper And Brass Coils.Our Designers Develop All The New Projects According To The Customer Needs And Requirements, So All Our Cut To Length Lines (CTL) Are Customized According To Individual Requirements.The Advanced Technology Of Our Cut To Length Lines (CTL) Ensures A Simple And Reliable Operation To Provide An Excellent Quality Of Finished Products.

-

2024-11-22cut to length machine-New Tech Machinery Portable Roll Formers: Side By Side ComparisonsYou’re ready to add a portable roll forming machine to your business and you’re shopping around to find the best equipment for you. New Tech Machinery is a leading manufacturer in the portable roll forming industry with a product line of machines that vary in terms of their specifications, features, length, and capabilities. Some of these specifications include maximum steel gauge, speed, panel types, panel width capacities, and of course, cost. At Western States Metal Roofing, we proudly manufacture standing seam panels and sell the painted metal coil for roll forming machines so we understand how important it is to choose the right machine for your business.

-

2024-11-22cut to length machine-Cut-to-length loggingCut-to-length logging (CTL) is a mechanized harvesting system in which trees are delimbed and cut to length directly at the stump. CTL is typically a two-man, two-machine operation with a harvester felling, delimbing, and bucking trees and a forwarder transporting the logs from the felling to a landing area close to a road accessible by trucks.The capital costs for a typical CTL operation, with one harvester and one forwarder, are quite high. The price of a pair of machines alone are approx. US$1,000,000.CTL is the primary logging method in European countries, while full-tree logging and the even older technique of tree-length logging are more popular in North America and less developed countries, where tree sizes can exceed the capacity of the harvester's felling head, i.e., tree stems with a butt diameter of over 90 centimeters. CTL lends itself to timber harvesting in plantation forestry where stems are often harvested before they reach large dimensions.

-

2024-11-22cut to length machine-Coil To Sheet Cut To Length MachineGuangdong Quanqi Machinery Equipment Co., Ltd. is specializing in R & D, production and manufacturing of metal Slitter, crosscutting machine, leveling machine, flying shear, metal longitudinal shear, stainless steel leveling machine, aluminum strip leveling machine, general steel leveling machine manufacturer and exporter. In combination with its own team advantages and advanced production management system, the company has formulated long-term R & D objectives, tasks and export instructions, requiring all products and spare parts produced to be higher than the national standards, higher than Taiwan's mechanical properties, and in line with the process and appearance of the top European and American manufacturers. The R & D team inherits the original Taiwan Tengqi process, and updates the design process in combination with customer feedback to achieve the goal of exceeding The advanced level of machinery and equipment in Taiwan. As a pure technology-based production and manufacturing enterprise, we regard products as art, and we will carve out the most perfect art for each customer, so that the products have the most stable and long-term use and life

-

2024-11-22metal roofing machine-An Introduction to Steel Cut to Length MachineA steel cut to length machine is also called the CTL line machine, cut to length lines, and heavy gauge lines. The steel cut to length machine is used for unrolling and cutting the heavy gauge strip material into the desired length, creating the final profiles. The steel cut to length machine is utilized for applications in the food and beverage industry, electronics, and construction equipment today. The CTL line machine typically processes the wide steel coils with high-performance cutters that can cut to precision lengths, quick tooling change system, decoiling, and stacking systems to produce the steel sheets or steel plates. Some cut to length machines also involves recoiling systems to achieve unique contours.

-

2024-11-22cut to length machine -What are tips for running Cut To Length MachineCut To Length Machine uses the working principle of multiple rollers , repeatedly deforms the sheet between the upper and lower working rollers, to eliminate stress and achieve the purpose of leveling.On the outer side of the upper and lower rows of working rollers, rigid supporting rollers are arranged to form 4HI or 6Hi roll-group structure. The sheet metal is leveled by straightenr , which can significantly improve its flatness and improve the quality of the workpiece . Straightener work independently for the leveling of a single sheet; can also be the whole assemble line with uncoiling ,guider ,shear ,stacker ete .It can be connected to a production line with complete performance through the control system to perform processing on metal coils. Leveling and slitting.Cut To Length Machine mainly depends on raw material thickness, material type and requirements of the strip. The thicker the material, the better the structural rigidity required, the fewer the number of rolls, the larger the roll length, the greater the power, and vice versa.

-

2024-11-22wire cut to length machine-cy for all applications.When making an investment in Cut-To-Length Machines, Durant is the solution for your requirements. Durant is a team building the machine suited particularly for your application. Durant can provide you with our standard feed body and electronics package or make necessary modifications at a very reasonable cost. Durant manufactures Servo Roll Feeds that provide power, speed, and precision feed accura

Related Search

- slitting line machine

- coil slitting line

- 1600mm high speed slitting line

- automatic steel sheet slitting line

- china coil slitting line manufacturers

- cut to length and slitting line

- metal slitting line

- slitting and cut to length line

- steel coil slitting line

- steel slitting line

- china slitting line machine

- coil slitting line manufacturer

- simple slitting line

- cut to lengh

- cut to lenght line

- cut to length machine

- floor deck forming machine factory

- roll forming line machine

- roll forming machine factory

- china roll forming machine factory

- silo roll forming machine factory

- steel silo roll forming machine factory

- wall panel roll forming machine factory

- aluminum corrugated roll forming machine factory

- aluminum roll forming machine factory

- angle bar roll forming machine factory

- angle iron roll forming machine factory

- angle roll forming machine factory

- angle steel roll forming machine factory

- arch roof roll forming machine factory