Detalles de producto

Light steel ceiling CU channel roll forming machine is widely used in ceiling and drywall construction. Compared with cement construction and wooden construction,steel frame is more light and durable.Thanks to these advantages,C channel roll forming machines and U channel roll forming machines are welcomed in the construction field.

Ceiling Channel Roll Forming Machine Advantages

1. High speed. Our high speed C/U/Omega stud channel roll forming machine speed can up to 40m/min.

Normally, C/U/Omega stud channel forming machine's speed is around 20-25m/min .

2. High durablity. Our rollers adopt the Cr 12 with quenched treatment,this is the best material for rollers.

3. High automatic. high speed C/U/Omega stud channel making machine adopts PLC systerm.

El usuario puede configurar la cantidad de producción, la velocidad de producción en el gabinete de control.

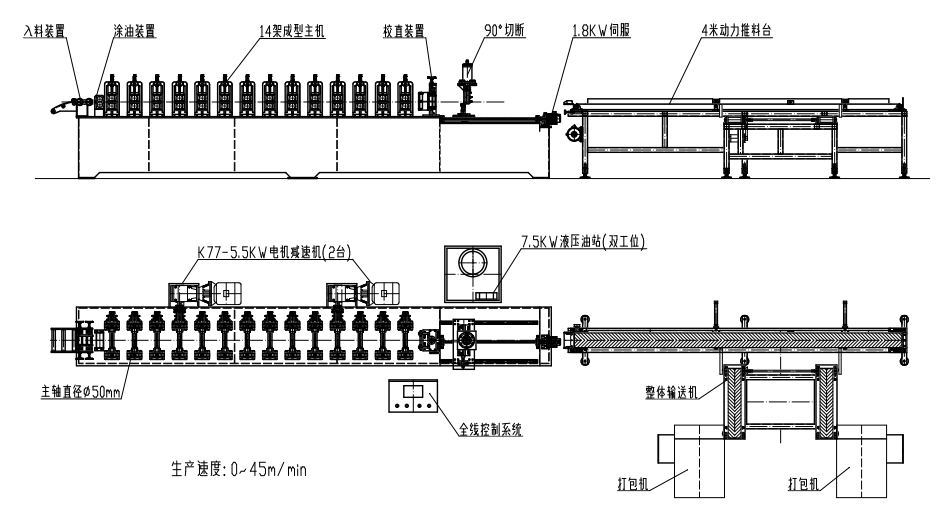

Ceiling Channel Roll Forming Machine Components

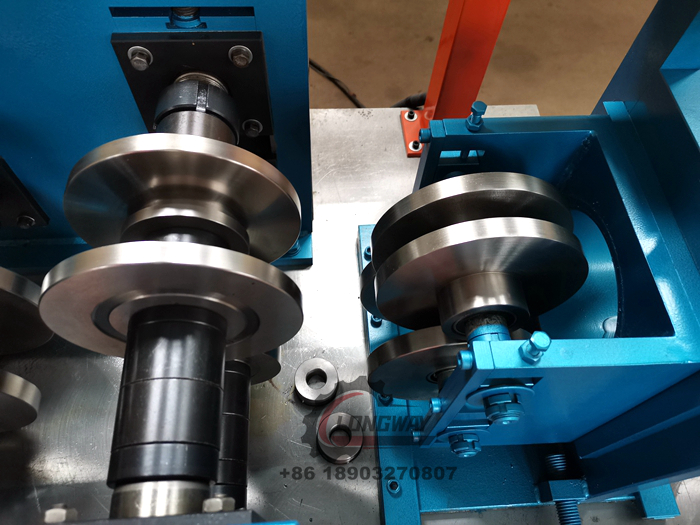

Roll forming stations: These stations consist of sets of rollers and dies arranged in sequence to progressively shape the metal coil into the desired profile.

Cut to length machine: Cutting blades integrated into the machine can precisely trim the formed channels to the required length.

Metal sheet punching machine: These units can punch holes or slots into the channels at specified intervals for mounting purposes or to accommodate accessories.

Material feeding system: Automated systems feed metal coils into the machine consistently, ensuring uninterrupted production.

Control system: Modern U channel roll forming machines are equipped with advanced control systems, often featuring touchscreens or computer interfaces, to set parameters, monitor production, and troubleshoot issues.

Adjustable tooling: Some roll forming machine for sale offer the flexibility to adjust the tooling to produce different sizes or profiles of ceiling channels, allowing for versatility in manufacturing.

Overall, a ceiling channel roll forming machine plays a crucial role in streamlining the production of ceiling components, contributing to the efficiency and quality of suspended ceiling systems used in various construction projects. As a roll forming equipment manufacturer,we provide products with reasonable ceiling channel machine price.

Ceiling Channel Roll Forming Machine Applications

Suspended Ceilings: Ceiling channels are commonly used in suspended ceiling systems where they provide support for ceiling tiles or panels. These systems are widely used in commercial buildings, offices, schools, hospitals, and other structures to conceal wiring, plumbing, and HVAC ducts while improving aesthetics and acoustics.

Drywall Framing: Ceiling channels are an integral part of drywall framing systems such as drywall roll forming machine used to construct interior walls and ceilings. They provide structural support for attaching gypsum boards or drywall panels, creating partition walls, and dividing interior spaces in residential, commercial, and industrial buildings.

Partition Walls: In office buildings, retail spaces, and other commercial settings, ceiling channels are utilized in partition wall systems such as máquina formadora de rollos de revestimiento para la venta to divide large areas into smaller rooms or cubicles. These systems offer flexibility, allowing for easy reconfiguration of space as needed.

Lighting Fixtures: Ceiling channels can also be used to mount lighting fixtures, such as fluorescent lights or LED panels, in both residential and commercial settings. The channels provide a stable base for securely attaching the fixtures to the ceiling while also accommodating wiring and electrical connections.

Decorative Applications: In addition to their functional roles, ceiling channel roll forming machine can be used for decorative purposes in architectural designs. They may be incorporated into ceiling designs to add visual interest, create geometric patterns, or define different areas within a space.

Soundproofing and Insulation: Ceiling channels can be part of systems designed to improve soundproofing and thermal insulation in buildings. By incorporating sound-absorbing materials or insulation batts between ceiling channels, these systems help reduce noise transmission and enhance energy efficiency.

Exterior Applications: In some cases, ceiling channel roll forming machine may also be used in exterior applications, such as soffits or eaves, to provide structural support and enhance the appearance of buildings' exteriors.

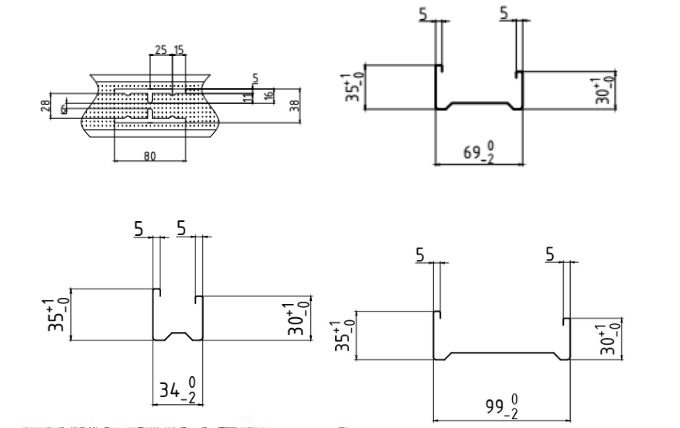

Aquí hay algunos perfiles de dibujo para su referencia:

Parámetros técnicos

Flujo de procesamiento

|

Serie

|

Detalles

|

Parámetro

|

Comentario

|

|

Material

|

Materia prima

|

Acero

|

Cliente confirmado

|

|

Espesor del material

|

0,4-0,6 mm

|

||

|

desbobinador

|

Estructura

|

Tipo pasivo manual

|

El estándar para que coincida con la línea de producción.

|

|

Tipo de cabeza única

|

|||

|

Capacidad de carga

|

1,5 toneladas

|

||

|

Diámetro interior de la bobina

|

450-550 mm

|

||

|

|

Dispositivo de guía

|

Colocado en la máquina por el vendedor

|

|

|

Material del eje rodante

|

45# ACERO

|

|

|

|

Diámetro del eje

|

50mm

|

|

|

|

Material del rodillo

|

GB-Cr12

|

|

|

|

estación rodante

|

12 estaciones

|

|

|

|

velocidad de trabajo

|

40 m/min

|

|

|

|

Estructura de la máquina

|

Marco de arco conmemorativo vertical

|

|

|

|

Estructura básica de la máquina

|

Placa de acero soldada

|

|

|

|

Cojinete

|

Rodamiento de rodillos

|

Famosa marca de Harbin

|

|

|

potencia de trabajo

|

4 kilovatios

|

|

|

|

Transmisión

|

por equipo

|

Con cubierta

|

|

|

Cubierta de seguridad

|

disponible

|

|

|

|

Apariencia

|

Buen aspecto sin rebabas en cuerpo de acero ni rastros de óxido o defectos de pintura.

Buena organización de cables eléctricos e hidráulicos La pintura del automóvil hace que la máquina sea más brillante |

Confirmamos que cada detalle puede coincidir con el estándar, ¡asegúrese de que la máquina sea 100% nueva!

|

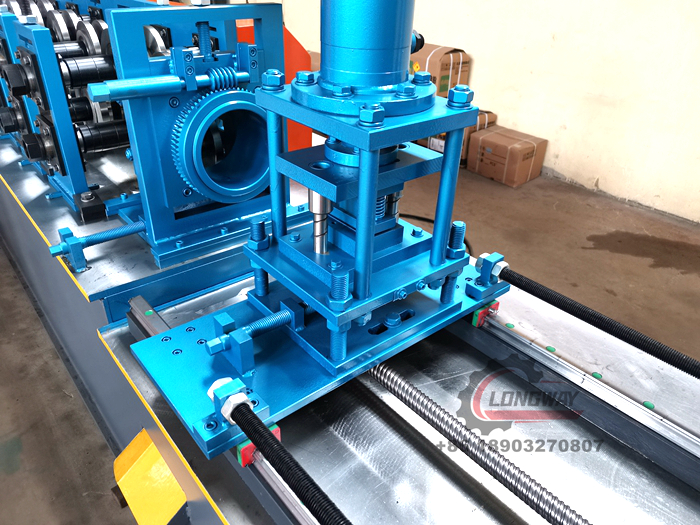

Imágenes detalladas de la máquina

Cada componente se puede diseñar según las necesidades personalizadas. La máquina formadora de rollos Longway proporciona OEM/ODM para todos los clientes

Aplicaciones

Las condiciones no compuestas son comunes en todas las estructuras. Cuando el panel de yeso se detiene en el nivel del techo, pero el montante continúa hasta la plataforma base, no se trata de una condición compuesta. El encuadre de pared con riel de deflexión, canal resistente (RC) o clips de sonido es un diseño no compuesto, ya que los tornillos que sujetan el panel de yeso no se sujetan directamente al encuadre o al riel superior. Si bien puede haber ventajas en contactar a los Servicios Técnicos o a un Profesional de Diseño, muchas condiciones pueden cubrirse con las tablas de alturas límite que se muestran en este catálogo.

Máquinas relacionadas

Cliente valioso de LONGWAY

-

Chile

-

Irán

-

filipino

-

Sudáfrica

Paquete y Entrega

1. Pulverización de aceite anticorrosivo en los rodillos para evitar la oxidación de los rodillos durante el envío

2. Máquina completa de película de aislamiento de embalaje para evitar la oxidación de la máquina durante el envío

3. Planificación de espacio razonable para reducir los costos de transporte para los clientes.

4. Bien arreglado para evitar daños a la máquina durante el período de tránsito

Pantalla de fábrica