Detalles de producto

Double Layer Roll Forming Machine Introduction

Double layer roll forming machine, also called double deck roll forming machine .

With 2 layers of guiding tables and the roll forming and máquina de corte a medida, double layer roll forming machines can produce two different roofing sheets with high efficiency. Generally speaking, double layer forming machine holds the following characteristics:

Cambio rápido y fácil entre 2 perfiles: opere en la pantalla del PLC, sin necesidad de cambiar o ajustar ninguna herramienta de rodillos.

Saving space and cost for the users.

Velocidad de producción: 10/20/30m/min opcional.

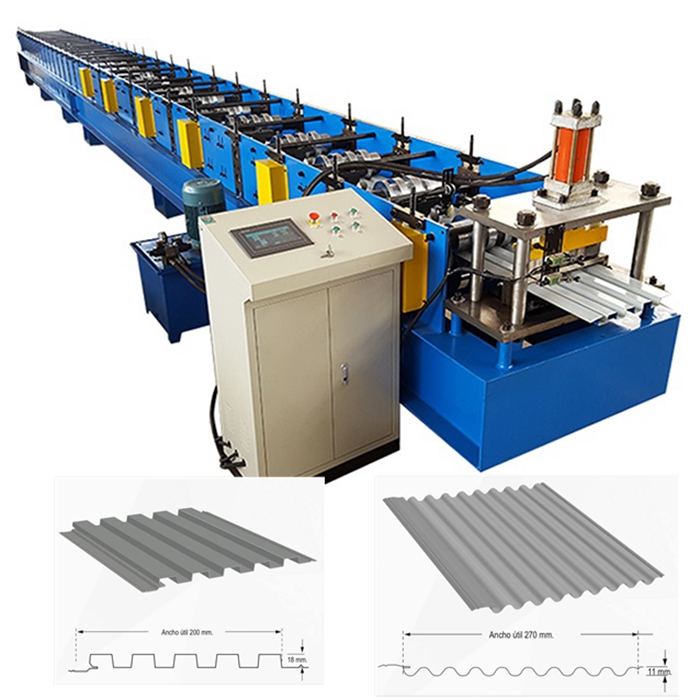

Dibujo de perfil para referencia:

Roofing sheet has many different shapes. Usually different countries have their own popular design. As a roll forming equipment manufacturer, we can customize the double deck roll forming machine as customers’ demand. This double layer forming machine can work two different profiles.

Dibujo de perfil para referencia:

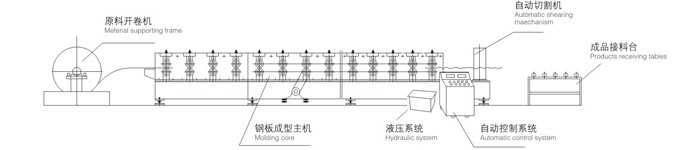

Double Layer Roll Forming Machine Working Process

Feeding: Metal coils are loaded onto the double layer roll forming machine. These coils can be made of various metals such as steel, aluminum, or copper.

Roll Forming: The metal coils pass through a series of rollers, each set of rollers responsible for shaping the metal into the desired profile. In a double deck roll forming machine, there are typically two sets of rollers, each forming a different profile.

Cutting: Once the metal has been formed into the desired shapes, it is cut to the required length by a cutting mechanism integrated into the machine.

Stacking or Collecting: The finished metal profiles are then either stacked for further processing or collected for packaging and shipping.

These double layer forming machines are used in various industries where there is a need for mass production of metal components with different profiles. Applications include roofing, wall cladding, automotive parts, and many others.

Double Layer Roll Forming Machine Applications

A double layer forming machine has a wide range of applications across various industries where there is a need for mass production of metal components with different profiles.

1. Roofing and Cladding: Double layer forming machines are extensively used in the construction industry for manufacturing metal roofing sheets and wall cladding panels. These machines can produce different profiles simultaneously, allowing for customization and versatility in design.

2. Automotive Industry: In the automotive sector, double layer forming machines are used to produce various components such as body panels, chassis parts, and trim pieces. The ability to form multiple layers simultaneously enables the efficient production of complex shapes required in vehicle manufacturing.

3. Furniture and Appliances: Metal components used in furniture and appliances, such as cabinets, shelves, and enclosures, can be manufactured using double layer forming machines. These double layer roll forming machines offer high precision and repeatability, making them suitable for producing components with tight tolerances.

4. Storage Systems: Double deck rool forming machines are employed in the fabrication of storage systems like shelving units, racks, and pallets used in warehouses, distribution centers, and retail stores.

5. Solar Panel Mounting Structures: With the growing demand for renewable energy solutions, double layer forming machines are utilized to manufacture mounting structures for solar panels. These structures require precise profiles to ensure optimal performance and durability, which can be achieved efficiently with such machines.

6. Agricultural Equipment: Components for agricultural machinery such as grain bins, silos, and equipment enclosures can be produced using double layer roll forming machines. These machines enable manufacturers to efficiently produce durable and weather-resistant components essential for agricultural operations.

Parámetros técnicos

Proceso de trabajo

Desenrollado → Material de alimentación en la máquina → Perfilado → Corte hidráulico → Mesa de recepción de productos

|

Materia prima |

Tipo de bobina |

PPGI, PPGL, GI |

|

Ancho |

1000/1200/1220 mm |

|

|

Rango de espesor |

Calibre 29-22 (0,3-0,6 mm) |

|

|

Requisitos de energía

|

Voltaje |

380v/3ph/50hz(Personalizado) |

|

Potencia del motor principal |

5.5kw |

|

|

Poder de corte |

4kw |

|

|

Velocidad de formación |

15-20 m/min |

|

|

Marco de la máquina |

Estructura de viga H de 350 mm |

|

|

Espesor de la estructura |

Placa de soporte central de acero soldado de 18 mm |

|

|

Eje de formación |

Eje macizo de 75 mm con tratamiento térmico |

|

|

Material de los rodillos |

Acero forjado de alto grado 45# |

|

|

Estaciones de formación |

14-18 filas Tipo de rodadura: concepto de diseño de rodadura separado, puede liberar la tensión interna de los pies, entonces la hoja estará en buena forma y con alta precisión |

|

|

Forma de transmisión |

Transmisión por cadena de 1 pulgada (Cadena doble) |

|

|

tipo de corte |

Corte tipo Pilar Hidráulico y corte longitudinal |

|

|

Sistema de control |

Delta del PLC y delta del inversor |

|

|

Pantalla |

Pantalla táctil |

|

|

Dimensión (aprox.) |

8,8 mx 1,5 mx 1,2 m |

|

|

Peso total (aproximado) |

7.6T |

|

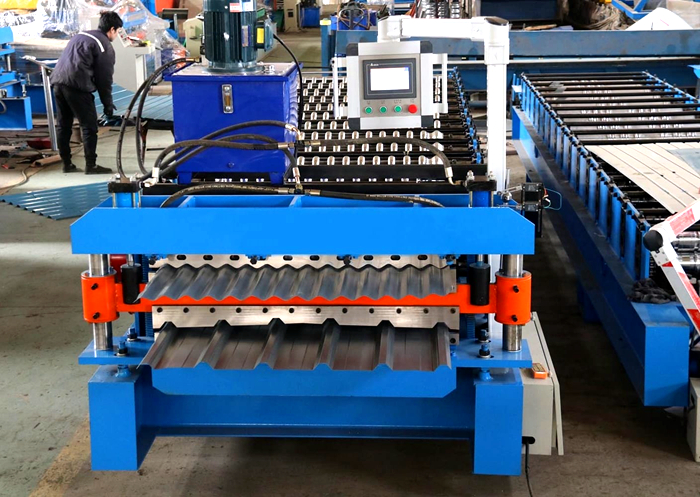

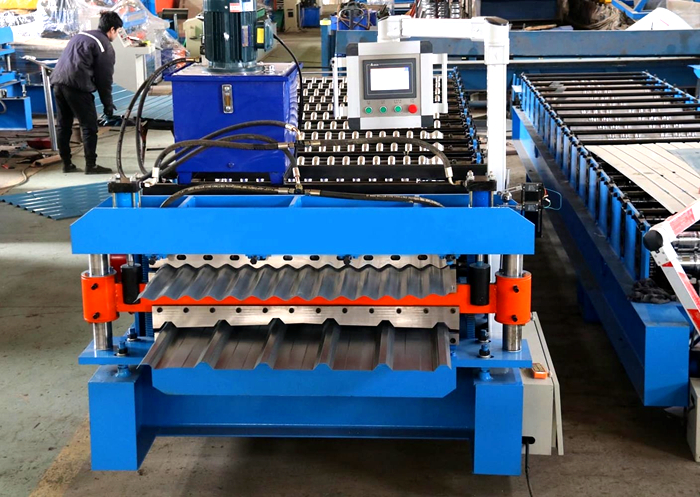

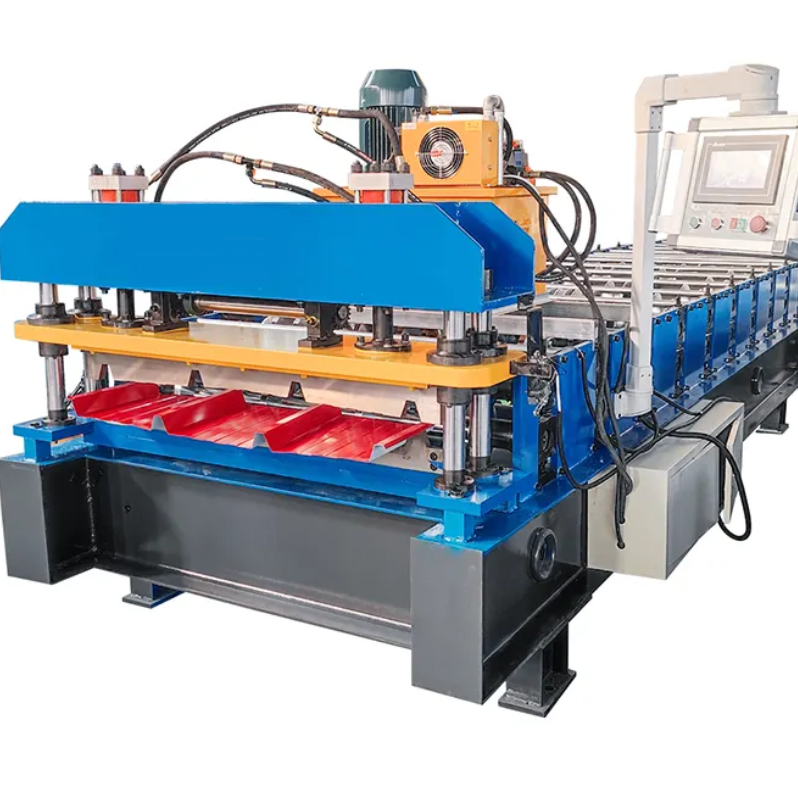

Imágenes detalladas de la máquina

Cada componente se puede diseñar según las necesidades personalizadas. La máquina formadora de rollos Longway proporciona OEM/ODM para todos los clientes

Aplicaciones

Aplicaciones de la máquina perfiladora de paneles de techo

Esta serie del perfil está diseñada para ser paneles de techo económicos para proyectos residenciales, industriales y comerciales.

Un mínimo de 0,30 mm y un máximo de 0,7 mm brinda más resistencia al daño.

Máquinas relacionadas

Cliente valioso de LONGWAY

-

Chile

-

Irán

-

filipino

-

Sudáfrica

Paquete y Entrega

1. Pulverización de aceite anticorrosivo en los rodillos para evitar la oxidación de los rodillos durante el envío

2. Máquina completa de película de aislamiento de embalaje para evitar la oxidación de la máquina durante el envío

3. Planificación de espacio razonable para reducir los costos de transporte para los clientes.

4. Bien arreglado para evitar daños a la máquina durante el período de tránsito

Pantalla de fábrica