detalji o proizvodu

Light steel ceiling CU channel roll forming machine is widely used in ceiling and drywall construction. Compared with cement construction and wooden construction,steel frame is more light and durable.Thanks to these advantages,C channel roll forming machines and U channel roll forming machines are welcomed in the construction field.

Ceiling Channel Roll Forming Machine Advantages

1. High speed. Our high speed C/U/Omega stud channel roll forming machine speed can up to 40m/min.

Normally, C/U/Omega stud channel forming machine's speed is around 20-25m/min .

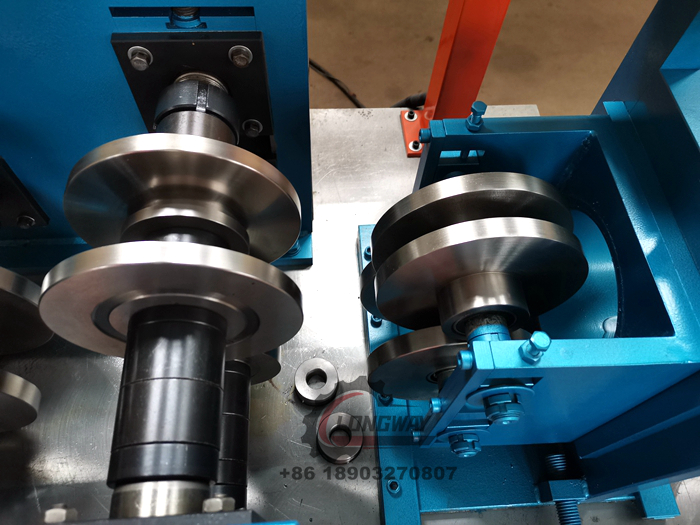

2. High durablity. Our rollers adopt the Cr 12 with quenched treatment,this is the best material for rollers.

3. High automatic. high speed C/U/Omega stud channel making machine adopts PLC systerm.

Korisnik može postaviti količinu proizvodnje, brzinu proizvodnje na upravljačkom ormaru.

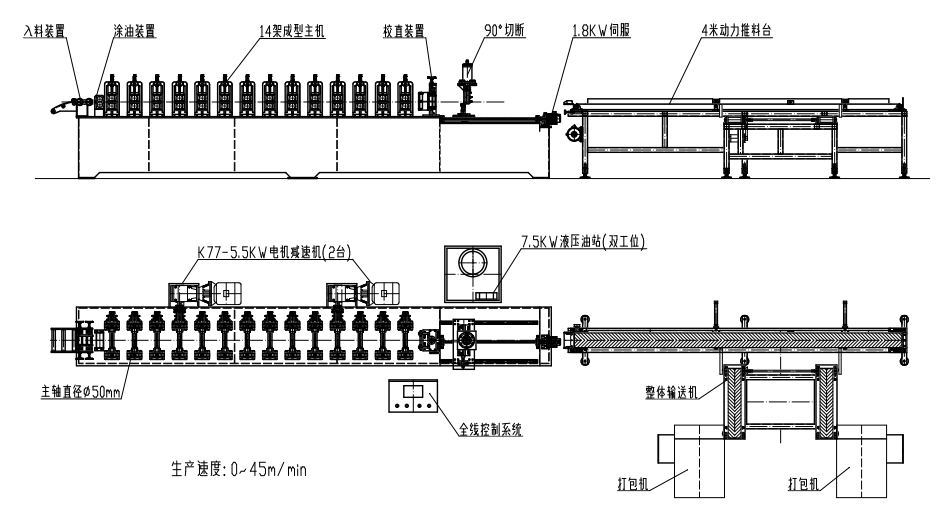

Ceiling Channel Roll Forming Machine Components

Roll forming stations: These stations consist of sets of rollers and dies arranged in sequence to progressively shape the metal coil into the desired profile.

Cut to length machine: Cutting blades integrated into the machine can precisely trim the formed channels to the required length.

Metal sheet punching machine: These units can punch holes or slots into the channels at specified intervals for mounting purposes or to accommodate accessories.

Material feeding system: Automated systems feed metal coils into the machine consistently, ensuring uninterrupted production.

Control system: Modern U channel roll forming machines are equipped with advanced control systems, often featuring touchscreens or computer interfaces, to set parameters, monitor production, and troubleshoot issues.

Adjustable tooling: Some roll forming machine for sale offer the flexibility to adjust the tooling to produce different sizes or profiles of ceiling channels, allowing for versatility in manufacturing.

Overall, a ceiling channel roll forming machine plays a crucial role in streamlining the production of ceiling components, contributing to the efficiency and quality of suspended ceiling systems used in various construction projects. As a roll forming equipment manufacturer,we provide products with reasonable ceiling channel machine price.

Ceiling Channel Roll Forming Machine Applications

Suspended Ceilings: Ceiling channels are commonly used in suspended ceiling systems where they provide support for ceiling tiles or panels. These systems are widely used in commercial buildings, offices, schools, hospitals, and other structures to conceal wiring, plumbing, and HVAC ducts while improving aesthetics and acoustics.

Drywall Framing: Ceiling channels are an integral part of drywall framing systems such as drywall roll forming machine used to construct interior walls and ceilings. They provide structural support for attaching gypsum boards or drywall panels, creating partition walls, and dividing interior spaces in residential, commercial, and industrial buildings.

Partition Walls: In office buildings, retail spaces, and other commercial settings, ceiling channels are utilized in partition wall systems such as stroj za oblikovanje valjaka za oblaganje na prodaju to divide large areas into smaller rooms or cubicles. These systems offer flexibility, allowing for easy reconfiguration of space as needed.

Lighting Fixtures: Ceiling channels can also be used to mount lighting fixtures, such as fluorescent lights or LED panels, in both residential and commercial settings. The channels provide a stable base for securely attaching the fixtures to the ceiling while also accommodating wiring and electrical connections.

Decorative Applications: In addition to their functional roles, ceiling channel roll forming machine can be used for decorative purposes in architectural designs. They may be incorporated into ceiling designs to add visual interest, create geometric patterns, or define different areas within a space.

Soundproofing and Insulation: Ceiling channels can be part of systems designed to improve soundproofing and thermal insulation in buildings. By incorporating sound-absorbing materials or insulation batts between ceiling channels, these systems help reduce noise transmission and enhance energy efficiency.

Exterior Applications: In some cases, ceiling channel roll forming machine may also be used in exterior applications, such as soffits or eaves, to provide structural support and enhance the appearance of buildings' exteriors.

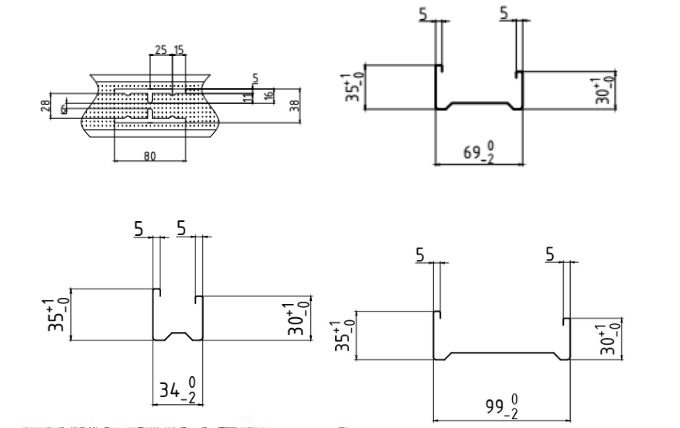

Evo nekoliko profila za crtanje za vašu referencu:

Tehnički farametri

Tijek obrade

|

Niz

|

pojedinosti

|

Parametar

|

Komentar

|

|

Materijal

|

Sirovina

|

Željezo

|

Kupac potvrđen

|

|

Debljina materijala

|

0,4-0,6 mm

|

||

|

Razmotavač

|

Struktura

|

Ručni pasivni tip

|

Standardni koji odgovara proizvodnoj liniji

|

|

Tip s jednom glavom

|

|||

|

Nosivost

|

1,5 tona

|

||

|

Unutarnji promjer zavojnice

|

450-550 mm

|

||

|

|

Uređaj za vođenje

|

Na stroj je postavio prodavač

|

|

|

Materijal kotrljajuće osovine

|

45# ČELIK

|

|

|

|

Promjer osovine

|

50 mm

|

|

|

|

Materijal valjka

|

GB-Cr12

|

|

|

|

Rolling station

|

12 postaja

|

|

|

|

Brzina rada

|

40 m/min

|

|

|

|

Struktura stroja

|

Okvir okomitog spomen luka

|

|

|

|

Osnovni okvir stroja

|

Čelična ploča zavarena

|

|

|

|

Ležaj

|

Valjkasti ležaj

|

Poznata marka iz Harbina

|

|

|

Radna snaga

|

4 kw

|

|

|

|

Prijenos

|

Po zupčaniku

|

Sa poklopcem

|

|

|

Sigurnosni poklopac

|

dostupno

|

|

|

|

Izgled

|

Dobar izgled bez neravnina na čeličnom tijelu niti tragova hrđe ili nedostataka u boji.

Dobra organizacija električnih i hidrauličkih kabela Lakiranje automobila čini stroj sjajnijim |

Potvrđujemo da svaki detalj može odgovarati standardu, osiguravamo da je stroj 100% nov!

|

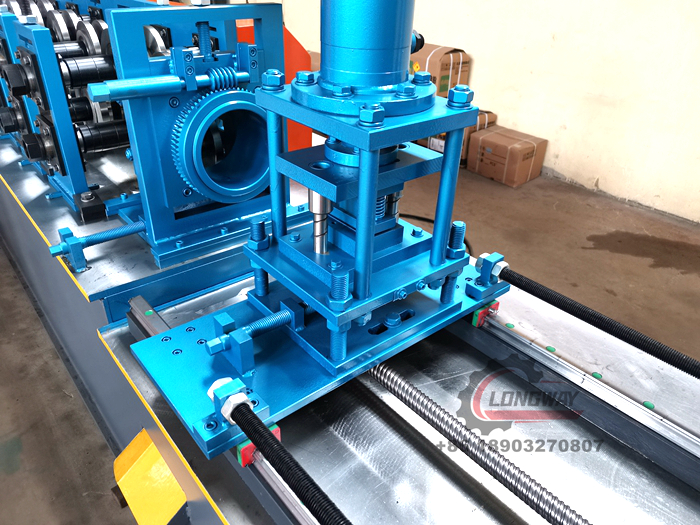

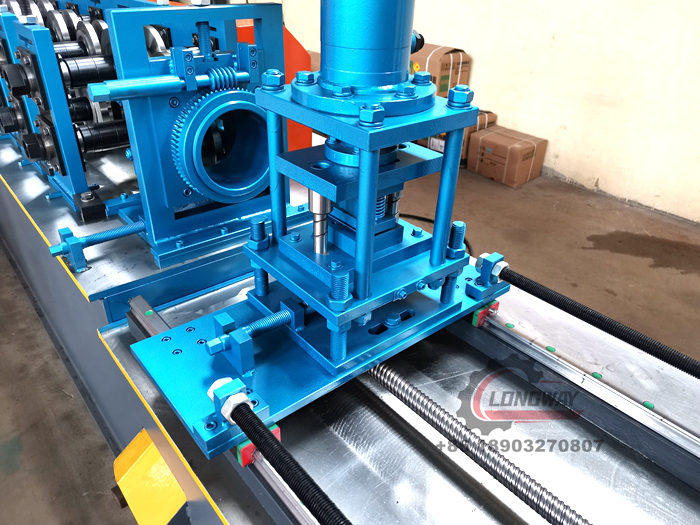

Detaljne slike stroja

Svaka komponenta može biti dizajnirana prema zahtjevima korisnika. Longway stroj za oblikovanje valjaka pruža OEM/ODM za sve kupce

Prijave

Nekompozitni uvjeti uobičajeni su u svim strukturama. Kada se gips ploča zaustavi na razini stropa, ali se klin nastavlja na palubu, to je nekompozitno stanje. Zidni okvir s otklonskom trakom, elastičnim kanalom (RC) ili zvučnim spojnicama nije kompozitni dizajn budući da vijci koji pričvršćuju gips ploču nisu izravno pričvršćeni na okvir ili gornju tračnicu. Iako može biti prednosti kontaktiranja tehničke službe ili stručnjaka za dizajn, mnogi se uvjeti mogu pokriti tablicama ograničenja visina prikazanim u ovom katalogu.

Povezani strojevi

LONGWAY vrijedan kupac

-

Čile

-

lran

-

filipinski

-

Južna Afrika

Paket i dostava

1 .Prskanje antikorozivnog ulja na valjke kako bi se spriječila oksidacija valjaka tijekom transporta

2. Izolacijska folija za pakiranje cijelog stroja kako bi se spriječila oksidacija stroja tijekom transporta

3.Razumno planiranje prostora za smanjenje troškova prijevoza za kupce

4. Dobro fiksiran kako bi se spriječilo oštećenje stroja tijekom razdoblja prijevoza

Tvornički zaslon