Rincian Produk

Light steel ceiling CU channel roll forming machine is widely used in ceiling and drywall construction. Compared with cement construction and wooden construction,steel frame is more light and durable.Thanks to these advantages,C channel roll forming machines and U channel roll forming machines are welcomed in the construction field.

Ceiling Channel Roll Forming Machine Advantages

1. High speed. Our high speed C/U/Omega stud channel roll forming machine speed can up to 40m/min.

Normally, C/U/Omega stud channel forming machine's speed is around 20-25m/min .

2. High durablity. Our rollers adopt the Cr 12 with quenched treatment,this is the best material for rollers.

3. High automatic. high speed C/U/Omega stud channel making machine adopts PLC systerm.

Pengguna dapat mengatur kuantitas produksi, kecepatan produksi pada kabinet kontrol.

Ceiling Channel Roll Forming Machine Components

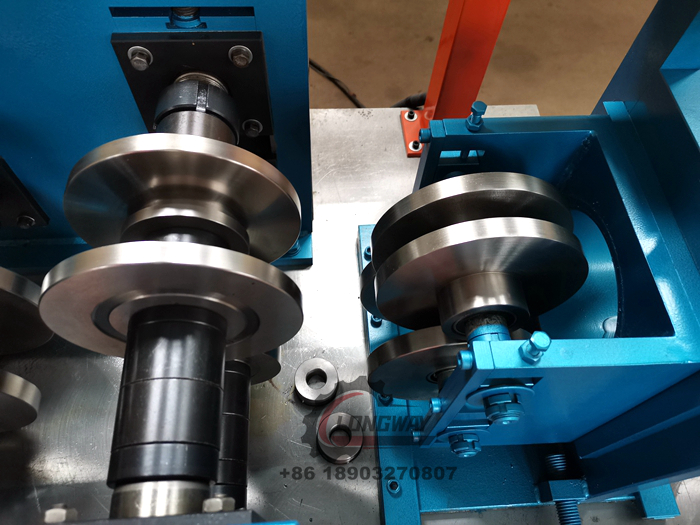

Roll forming stations: These stations consist of sets of rollers and dies arranged in sequence to progressively shape the metal coil into the desired profile.

Cut to length machine: Cutting blades integrated into the machine can precisely trim the formed channels to the required length.

Metal sheet punching machine: These units can punch holes or slots into the channels at specified intervals for mounting purposes or to accommodate accessories.

Material feeding system: Automated systems feed metal coils into the machine consistently, ensuring uninterrupted production.

Control system: Modern U channel roll forming machines are equipped with advanced control systems, often featuring touchscreens or computer interfaces, to set parameters, monitor production, and troubleshoot issues.

Adjustable tooling: Some roll forming machine for sale offer the flexibility to adjust the tooling to produce different sizes or profiles of ceiling channels, allowing for versatility in manufacturing.

Overall, a ceiling channel roll forming machine plays a crucial role in streamlining the production of ceiling components, contributing to the efficiency and quality of suspended ceiling systems used in various construction projects. As a roll forming equipment manufacturer,we provide products with reasonable ceiling channel machine price.

Ceiling Channel Roll Forming Machine Applications

Suspended Ceilings: Ceiling channels are commonly used in suspended ceiling systems where they provide support for ceiling tiles or panels. These systems are widely used in commercial buildings, offices, schools, hospitals, and other structures to conceal wiring, plumbing, and HVAC ducts while improving aesthetics and acoustics.

Drywall Framing: Ceiling channels are an integral part of drywall framing systems such as drywall roll forming machine used to construct interior walls and ceilings. They provide structural support for attaching gypsum boards or drywall panels, creating partition walls, and dividing interior spaces in residential, commercial, and industrial buildings.

Partition Walls: In office buildings, retail spaces, and other commercial settings, ceiling channels are utilized in partition wall systems such as jual mesin cladding roll forming to divide large areas into smaller rooms or cubicles. These systems offer flexibility, allowing for easy reconfiguration of space as needed.

Lighting Fixtures: Ceiling channels can also be used to mount lighting fixtures, such as fluorescent lights or LED panels, in both residential and commercial settings. The channels provide a stable base for securely attaching the fixtures to the ceiling while also accommodating wiring and electrical connections.

Decorative Applications: In addition to their functional roles, ceiling channel roll forming machine can be used for decorative purposes in architectural designs. They may be incorporated into ceiling designs to add visual interest, create geometric patterns, or define different areas within a space.

Soundproofing and Insulation: Ceiling channels can be part of systems designed to improve soundproofing and thermal insulation in buildings. By incorporating sound-absorbing materials or insulation batts between ceiling channels, these systems help reduce noise transmission and enhance energy efficiency.

Exterior Applications: In some cases, ceiling channel roll forming machine may also be used in exterior applications, such as soffits or eaves, to provide structural support and enhance the appearance of buildings' exteriors.

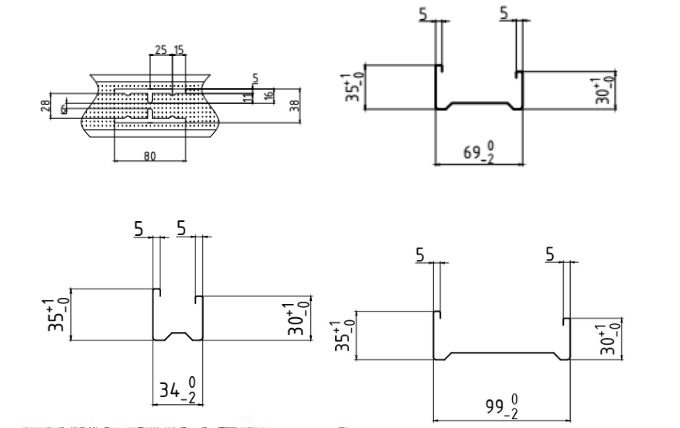

Berikut adalah beberapa profil gambar untuk referensi Anda:

Farameter Teknis

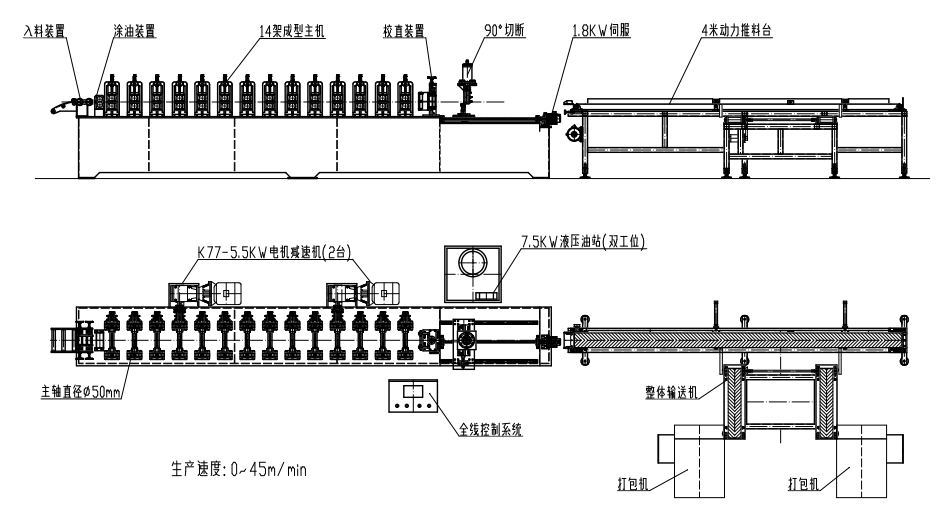

Alur Pemrosesan

|

Seri

|

Detail

|

Parameter

|

Komentar

|

|

Bahan

|

Bahan baku

|

Baja

|

Pelanggan dikonfirmasi

|

|

Ketebalan bahan

|

0,4-0,6 mm

|

||

|

Decoiler

|

Struktur

|

Tipe pasif manual

|

Yang standar untuk mencocokkan jalur produksi

|

|

Tipe kepala tunggal

|

|||

|

Kapasitas pemuatan

|

1,5 Ton

|

||

|

Diameter dalam kumparan

|

450-550 mm

|

||

|

|

Perangkat pemandu

|

Ditempatkan di mesin oleh penjual

|

|

|

Bahan poros bergulir

|

45 # BAJA

|

|

|

|

Diameter poros

|

50 mm

|

|

|

|

Bahan rol

|

GB-Cr12

|

|

|

|

Stasiun bergulir

|

12 stasiun

|

|

|

|

Kecepatan kerja

|

40 m/mnt

|

|

|

|

Struktur mesin

|

Bingkai lengkungan peringatan vertikal

|

|

|

|

Rangka dasar mesin

|

Pelat baja dilas

|

|

|

|

Bantalan

|

Bantalan poros

|

Merek terkenal dari Harbin

|

|

|

Kekuatan kerja

|

4kw

|

|

|

|

Penularan

|

Dengan roda gigi

|

Dengan penutup

|

|

|

Penutup pengaman

|

tersedia

|

|

|

|

Penampilan

|

Penampilan bagus tanpa gerinda pada bodi baja atau bekas karat atau cacat pada pengecatan.

Organisasi kabel listrik dan hidrolik yang baik Pengecatan mobil membuat mesin lebih mengkilap |

Kami mengonfirmasi setiap detail dapat sesuai dengan standar, memastikan mesin 100% baru!

|

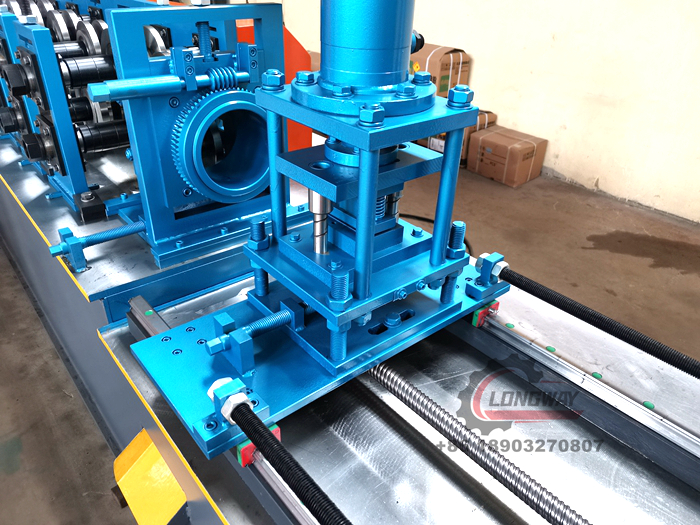

Gambar Detail Mesin

Setiap komponen dapat dirancang sesuai kebutuhan khusus. Mesin roll forming panjang menyediakan OEM / ODM untuk semua pelanggan

Aplikasi

Kondisi non-komposit umum terjadi di semua struktur. Ketika papan gipsum berhenti di tingkat langit-langit, tetapi tiang berlanjut ke geladak, itu adalah kondisi non-komposit. Pembingkaian dinding dengan Defleksi Track, Resilient Channel (RC) atau Sound Clips adalah desain non-komposit karena sekrup yang memasang papan gypsum tidak langsung dipasang ke pembingkaian atau track atas. Meskipun mungkin ada keuntungan menghubungi Layanan Teknis atau Profesional Desain, banyak kondisi yang dapat dicakup dengan membatasi tabel ketinggian yang diperlihatkan dalam katalog ini .

Mesin Terkait

Pelanggan berharga JAUH

-

Chili

-

lran

-

Filipina

-

Afrika Selatan

Paket dan Pengiriman

1. Menyemprotkan minyak anti-korosif pada rol untuk mencegah oksidasi rol selama pengiriman

2.Packaging film isolasi seluruh mesin untuk mencegah oksidasi mesin selama pengiriman

3. Perencanaan ruang yang masuk akal untuk mengurangi biaya transportasi bagi pelanggan

4. Memperbaiki dengan baik untuk mencegah kerusakan mesin selama masa transit

Tampilan Pabrik