détails du produit

Light steel ceiling CU channel roll forming machine is widely used in ceiling and drywall construction. Compared with cement construction and wooden construction,steel frame is more light and durable.Thanks to these advantages,C channel roll forming machines and U channel roll forming machines are welcomed in the construction field.

Ceiling Channel Roll Forming Machine Advantages

1. High speed. Our high speed C/U/Omega stud channel roll forming machine speed can up to 40m/min.

Normally, C/U/Omega stud channel forming machine's speed is around 20-25m/min .

2. High durablity. Our rollers adopt the Cr 12 with quenched treatment,this is the best material for rollers.

3. High automatic. high speed C/U/Omega stud channel making machine adopts PLC systerm.

L'utilisateur peut définir la quantité de production, la vitesse de production sur l'armoire de commande.

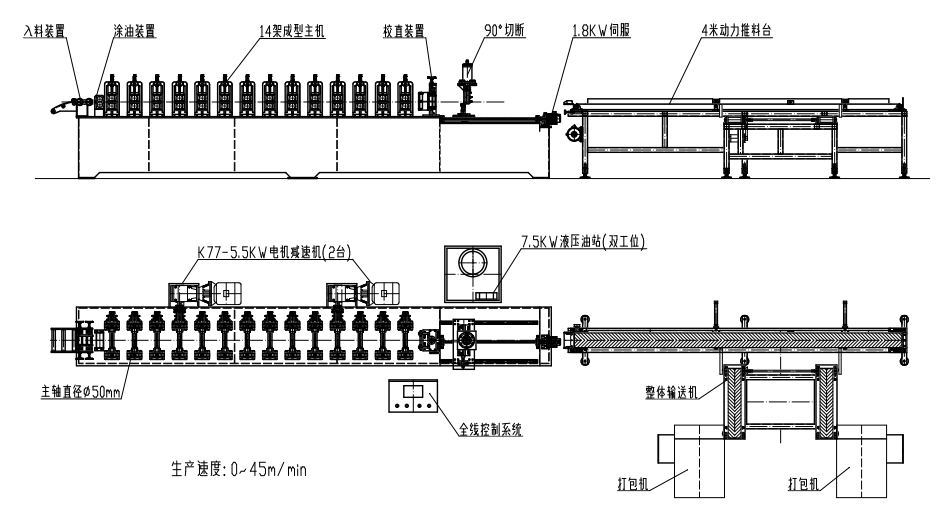

Ceiling Channel Roll Forming Machine Components

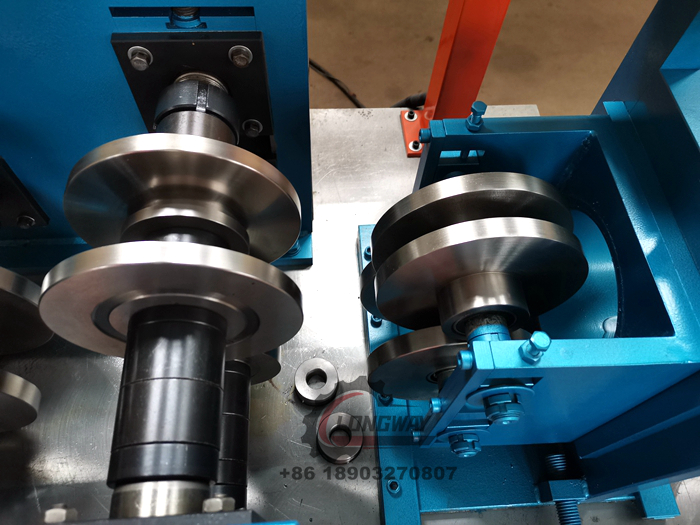

Roll forming stations: These stations consist of sets of rollers and dies arranged in sequence to progressively shape the metal coil into the desired profile.

Cut to length machine: Cutting blades integrated into the machine can precisely trim the formed channels to the required length.

Metal sheet punching machine: These units can punch holes or slots into the channels at specified intervals for mounting purposes or to accommodate accessories.

Material feeding system: Automated systems feed metal coils into the machine consistently, ensuring uninterrupted production.

Control system: Modern U channel roll forming machines are equipped with advanced control systems, often featuring touchscreens or computer interfaces, to set parameters, monitor production, and troubleshoot issues.

Adjustable tooling: Some roll forming machine for sale offer the flexibility to adjust the tooling to produce different sizes or profiles of ceiling channels, allowing for versatility in manufacturing.

Overall, a ceiling channel roll forming machine plays a crucial role in streamlining the production of ceiling components, contributing to the efficiency and quality of suspended ceiling systems used in various construction projects. As a roll forming equipment manufacturer,we provide products with reasonable ceiling channel machine price.

Ceiling Channel Roll Forming Machine Applications

Suspended Ceilings: Ceiling channels are commonly used in suspended ceiling systems where they provide support for ceiling tiles or panels. These systems are widely used in commercial buildings, offices, schools, hospitals, and other structures to conceal wiring, plumbing, and HVAC ducts while improving aesthetics and acoustics.

Drywall Framing: Ceiling channels are an integral part of drywall framing systems such as drywall roll forming machine used to construct interior walls and ceilings. They provide structural support for attaching gypsum boards or drywall panels, creating partition walls, and dividing interior spaces in residential, commercial, and industrial buildings.

Partition Walls: In office buildings, retail spaces, and other commercial settings, ceiling channels are utilized in partition wall systems such as rouleau de revêtement formant la machine à vendre to divide large areas into smaller rooms or cubicles. These systems offer flexibility, allowing for easy reconfiguration of space as needed.

Lighting Fixtures: Ceiling channels can also be used to mount lighting fixtures, such as fluorescent lights or LED panels, in both residential and commercial settings. The channels provide a stable base for securely attaching the fixtures to the ceiling while also accommodating wiring and electrical connections.

Decorative Applications: In addition to their functional roles, ceiling channel roll forming machine can be used for decorative purposes in architectural designs. They may be incorporated into ceiling designs to add visual interest, create geometric patterns, or define different areas within a space.

Soundproofing and Insulation: Ceiling channels can be part of systems designed to improve soundproofing and thermal insulation in buildings. By incorporating sound-absorbing materials or insulation batts between ceiling channels, these systems help reduce noise transmission and enhance energy efficiency.

Exterior Applications: In some cases, ceiling channel roll forming machine may also be used in exterior applications, such as soffits or eaves, to provide structural support and enhance the appearance of buildings' exteriors.

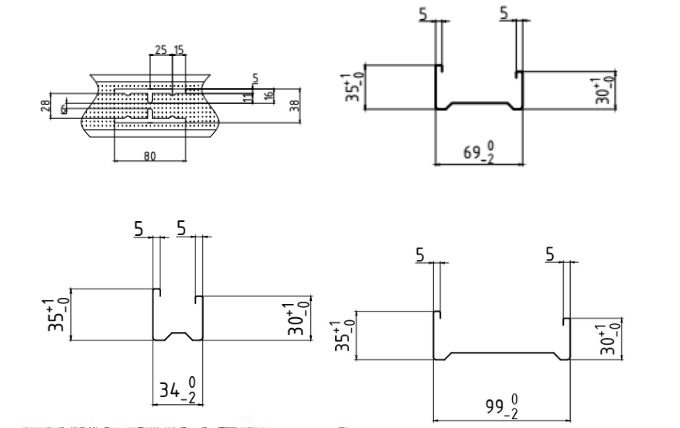

Voici quelques profils de dessin pour votre référence :

Faramètres techniques

Flux de traitement

|

Série

|

Détails

|

Paramètre

|

Commentaire

|

|

Matériel

|

Matière première

|

Acier

|

Client confirmé

|

|

Épaisseur de matériau

|

0,4-0,6 millimètres

|

||

|

Dérouleur

|

Structure

|

Type passif manuel

|

Le standard pour correspondre à la ligne de production

|

|

Type à tête unique

|

|||

|

Capacité de chargement

|

1,5 tonne

|

||

|

Diamètre intérieur de la bobine

|

450-550 millimètres

|

||

|

|

Dispositif de guidage

|

Placé sur la machine par le vendeur

|

|

|

Matériau de l'arbre roulant

|

45 # ACIER

|

|

|

|

Diamètre de l'arbre

|

50 millimètres

|

|

|

|

Matériau du rouleau

|

GB-Cr12

|

|

|

|

Station de roulement

|

12 stations

|

|

|

|

Vitesse de travail

|

40 m/min

|

|

|

|

Structure de la machine

|

Cadre d'arc commémoratif vertical

|

|

|

|

Châssis de base de la machine

|

Tôle d'acier soudée

|

|

|

|

Palier

|

Roulement à rouleaux

|

Célèbre marque de Harbin

|

|

|

Puissance de travail

|

4 kW

|

|

|

|

Transmission

|

Par engrenage

|

Avec couverture

|

|

|

Coque de protection

|

disponible

|

|

|

|

Apparence

|

Bon aspect sans bavures dans le corps en acier ni traces de rouille ou défauts de peinture.

Bonne organisation des câbles électriques et hydrauliques La peinture de voiture rend la machine plus brillante |

Nous confirmons que chaque détail peut correspondre à la norme, assurez-vous que la machine est 100 % neuve.

|

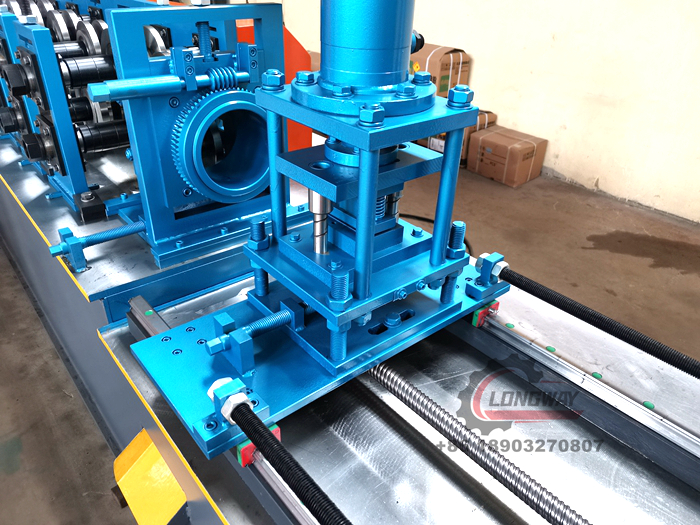

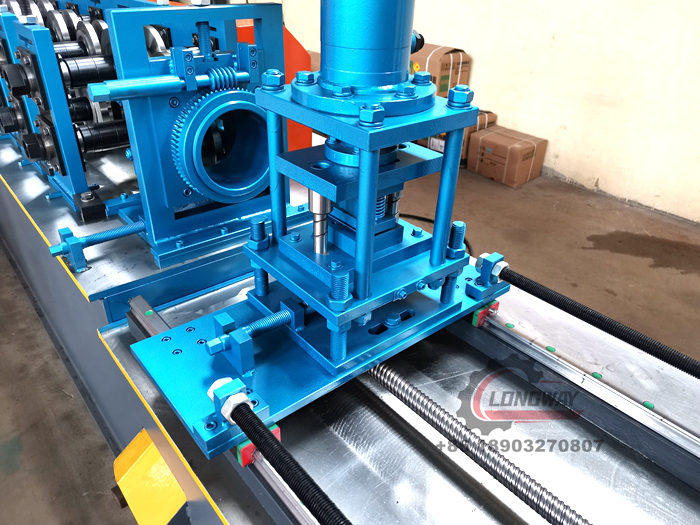

Images détaillées de la machine

Chaque composant peut être conçu selon les besoins personnalisés. La machine de formage de rouleaux Longway fournit OEM/ODM pour tous les clients

Applications

Les conditions non composites sont communes à toutes les structures. Lorsque la plaque de plâtre s'arrête au niveau du plafond, mais que le poteau continue jusqu'au pont, il s'agit d'une condition non composite. L'ossature murale avec rail de déviation, profilé résilient (RC) ou attaches acoustiques est une conception non composite puisque les vis fixant la plaque de plâtre ne sont pas directement fixées à l'ossature ou au rail supérieur. Bien qu'il puisse y avoir des avantages à contacter les services techniques ou un professionnel de la conception, de nombreuses conditions peuvent être couvertes par les tableaux de hauteurs limites présentés dans ce catalogue .

Appareils associés

LONGWAY précieux client

-

Chili

-

lran

-

Philippine

-

Afrique du Sud

Colis et livraison

1. Pulvérisation d'huile anticorrosion sur les rouleaux pour empêcher l'oxydation des rouleaux pendant l'expédition

2. Machine entière de film d'isolation d'emballage pour empêcher l'oxydation de machine pendant l'expédition

3. Planification de l'espace raisonnable pour réduire les coûts de transport pour les clients

4. Fixé bien pour éviter d'endommager la machine pendant la période de transit

Affichage d'usine