Jan . 26, 2025 02:14

Back to list

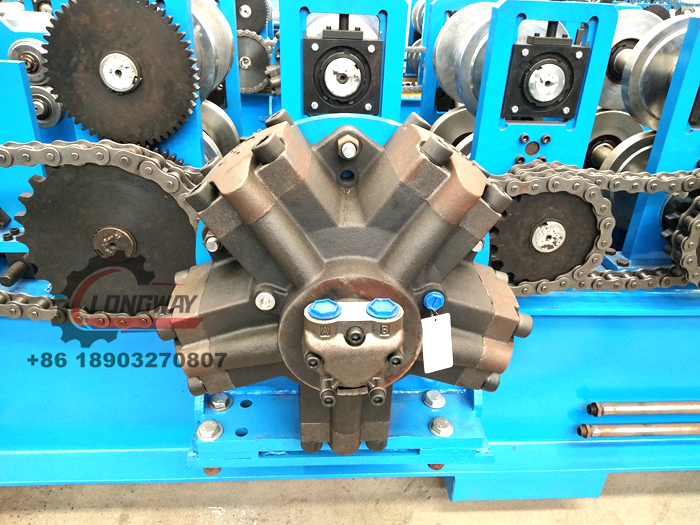

3 Rib Trapezoid roof sheet making machine

Purchasing a steel roof sheet making machine is a significant investment that requires careful consideration of various factors, particularly the price. Understanding the pricing of these machines goes beyond just the sticker value; it requires a deep dive into the factors that contribute to the total cost of ownership, operational efficiency, and long-term benefits for your business.

Purchasers must also consider the potential for customization required for unique business needs. Custom features may result in a higher price, but they often provide significant advantages in differentiating products in the market or optimizing them for particular applications. Operational efficiency and the total cost of ownership are crucial considerations. While initial prices can serve as a benchmark, operational efficiencies, including energy consumption, maintenance cycles, and production waste, will ultimately influence the long-term value of the investment. Machines designed for energy efficiency and minimal waste output might have a higher upfront cost but often yield the best return on investment. The adoption of the latest technologies, including IoT and AI enhancements, is another factor that can influence the price. These advancements can significantly optimize the production process through real-time monitoring and predictive maintenance, minimizing unplanned downtimes and further contributing to the overall cost-effectiveness of the machine. In exploring the financial aspects, potential buyers should not disregard financing options or leasing arrangements offered by manufacturers. These options can make higher-priced machines more accessible by spreading the cost over time. Finally, industry trends should be a consideration. With the global shift towards sustainable practices, machines that provide environmentally friendly production capabilities are becoming increasingly valuable. Although they may cost more initially, aligning with sustainable practices can boost a company's brand appeal and potentially open up new market opportunities. In conclusion, while the price of a steel roof sheet making machine can be daunting, a careful analysis of all contributing factors provides a clearer picture of the value proposition. Evaluating long-term operational benefits, quality components, production capacity, and technological advancements against the initial investment can help businesses make informed decisions, ensuring they choose a machine that meets their present needs and supports future growth objectives.

Purchasers must also consider the potential for customization required for unique business needs. Custom features may result in a higher price, but they often provide significant advantages in differentiating products in the market or optimizing them for particular applications. Operational efficiency and the total cost of ownership are crucial considerations. While initial prices can serve as a benchmark, operational efficiencies, including energy consumption, maintenance cycles, and production waste, will ultimately influence the long-term value of the investment. Machines designed for energy efficiency and minimal waste output might have a higher upfront cost but often yield the best return on investment. The adoption of the latest technologies, including IoT and AI enhancements, is another factor that can influence the price. These advancements can significantly optimize the production process through real-time monitoring and predictive maintenance, minimizing unplanned downtimes and further contributing to the overall cost-effectiveness of the machine. In exploring the financial aspects, potential buyers should not disregard financing options or leasing arrangements offered by manufacturers. These options can make higher-priced machines more accessible by spreading the cost over time. Finally, industry trends should be a consideration. With the global shift towards sustainable practices, machines that provide environmentally friendly production capabilities are becoming increasingly valuable. Although they may cost more initially, aligning with sustainable practices can boost a company's brand appeal and potentially open up new market opportunities. In conclusion, while the price of a steel roof sheet making machine can be daunting, a careful analysis of all contributing factors provides a clearer picture of the value proposition. Evaluating long-term operational benefits, quality components, production capacity, and technological advancements against the initial investment can help businesses make informed decisions, ensuring they choose a machine that meets their present needs and supports future growth objectives.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products