Jan . 26, 2025 02:37

Back to list

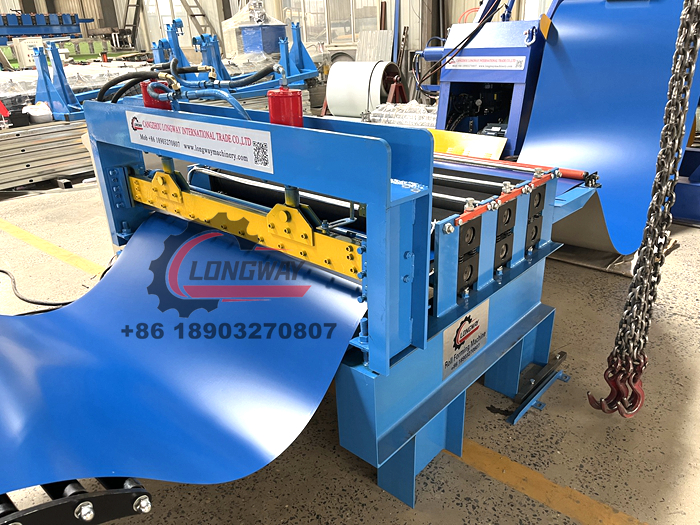

Maquina para panel micro acanalado/ondulado 762/1020

In the dynamic world of construction and road safety, highway guardrail making machines stand out as a pivotal innovation for enhancing roadway protection. These machines are expertly designed to manufacture high-quality guardrails that serve as vital components in ensuring the safety of drivers and pedestrians alike. With a robust focus on experience, expertise, authoritativeness, and trustworthiness, this article delves into the intricacies of this essential machinery.

Authoritativeness The reputation of highway guardrail making machines in the industry is backed by authoritative endorsements from leading safety organizations and regulatory bodies. These machines are often the preferred choice of contractors and municipal agencies globally, owing to their compliance with international safety standards. Many manufacturers of these machines are ISO certified, a testament to their commitment to quality and safety. The documented performance of these machines in improving road safety statistics further cements their authoritative status in the marketplace. Trustworthiness Trust in highway guardrail making machines is built on a foundation of proven reliability and consistent performance. Users benefit from comprehensive warranties and excellent after-sales service, which includes technical support and access to a network of parts and maintenance solutions. Manufacturers often conduct rigorous quality control checks and offer detailed operational training, ensuring that their machines deliver optimum performance with minimal downtime. Testimonials from satisfied clients reinforce the trust placed in these machines, highlighting their role in enhancing road safety and contributing to community well-being. In conclusion, highway guardrail making machines embody a blend of experience, expertise, authoritativeness, and trustworthiness, making them an indispensable asset in the quest for safer roads. Their contribution to producing robust guardrails cannot be overstated, offering protection and peace of mind to millions of road users worldwide. Those seeking to invest in this technology can be assured of its superior quality, which is backed by a rich legacy of engineering excellence and a steadfast commitment to public safety.

Authoritativeness The reputation of highway guardrail making machines in the industry is backed by authoritative endorsements from leading safety organizations and regulatory bodies. These machines are often the preferred choice of contractors and municipal agencies globally, owing to their compliance with international safety standards. Many manufacturers of these machines are ISO certified, a testament to their commitment to quality and safety. The documented performance of these machines in improving road safety statistics further cements their authoritative status in the marketplace. Trustworthiness Trust in highway guardrail making machines is built on a foundation of proven reliability and consistent performance. Users benefit from comprehensive warranties and excellent after-sales service, which includes technical support and access to a network of parts and maintenance solutions. Manufacturers often conduct rigorous quality control checks and offer detailed operational training, ensuring that their machines deliver optimum performance with minimal downtime. Testimonials from satisfied clients reinforce the trust placed in these machines, highlighting their role in enhancing road safety and contributing to community well-being. In conclusion, highway guardrail making machines embody a blend of experience, expertise, authoritativeness, and trustworthiness, making them an indispensable asset in the quest for safer roads. Their contribution to producing robust guardrails cannot be overstated, offering protection and peace of mind to millions of road users worldwide. Those seeking to invest in this technology can be assured of its superior quality, which is backed by a rich legacy of engineering excellence and a steadfast commitment to public safety.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products