Jan . 26, 2025 01:52

Back to list

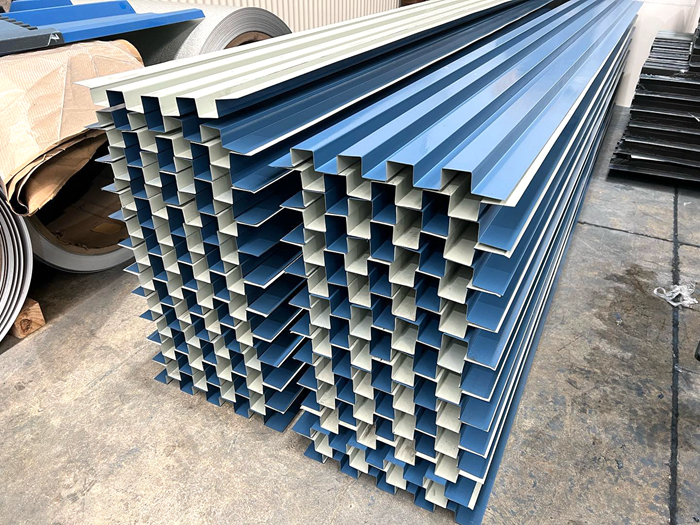

US Metal Roofing Ag and R panel Roll Former

When exploring the landscape of roofing technology, standing seam panel machines emerge as indispensable assets. These devices are essential for industries aiming to fabricate roofing panels that are not only durable but also aesthetically appealing. Delving into the intricacies of standing seam machines unveils their significance in architectural manufacturing and sheds light on their technical aspects, benefits, and purchasing considerations.

In assessing the credibility and trustworthiness of standing seam machines available for sale, it’s prudent to consider the reputation of manufacturers and suppliers. Leading manufacturers offer extensive support, including training, warranties, and after-sales service, crucial for a seamless transition and sustained operation. Reviews and testimonials from industry peers can offer insights into real-world performance, reliability, and the overall satisfaction of existing users. Verifying these aspects can prevent potential pitfalls and ensure the acquisition of a machine that delivers on its promises. For those intent on purchasing a standing seam panel machine, the economic considerations form a notable focus area. While the initial investment can be substantial, the long-term gains manifest in reduced labor costs, increased production efficiency, and the ability to meet high-demand outputs with consistency. It's wise to perform a return on investment analysis, factoring in potential increases in business capacity and profitability. A foray into purchasing standing seam panel machines is not merely about acquiring equipment; it’s about establishing a foundation for superior craftsmanship and operational excellence. Equipped with this knowledge, businesses can capitalize on this technology to deliver unparalleled roofing solutions, distinguishing themselves in a competitive marketplace. For individuals or companies on the cusp of expansion into roofing solutions, the awareness of market dynamics and technological advancements in standing seam panel machinery is invaluable. As architectural trends evolve, the need for adaptive, reliable, and efficient machinery becomes more pronounced, ensuring that those equipped with the best tools remain at the forefront of industry innovation. By aligning purchases with strategic objectives, stakeholders can secure a tangible edge, marked by superior quality, innovative design, and operational proficiency.

In assessing the credibility and trustworthiness of standing seam machines available for sale, it’s prudent to consider the reputation of manufacturers and suppliers. Leading manufacturers offer extensive support, including training, warranties, and after-sales service, crucial for a seamless transition and sustained operation. Reviews and testimonials from industry peers can offer insights into real-world performance, reliability, and the overall satisfaction of existing users. Verifying these aspects can prevent potential pitfalls and ensure the acquisition of a machine that delivers on its promises. For those intent on purchasing a standing seam panel machine, the economic considerations form a notable focus area. While the initial investment can be substantial, the long-term gains manifest in reduced labor costs, increased production efficiency, and the ability to meet high-demand outputs with consistency. It's wise to perform a return on investment analysis, factoring in potential increases in business capacity and profitability. A foray into purchasing standing seam panel machines is not merely about acquiring equipment; it’s about establishing a foundation for superior craftsmanship and operational excellence. Equipped with this knowledge, businesses can capitalize on this technology to deliver unparalleled roofing solutions, distinguishing themselves in a competitive marketplace. For individuals or companies on the cusp of expansion into roofing solutions, the awareness of market dynamics and technological advancements in standing seam panel machinery is invaluable. As architectural trends evolve, the need for adaptive, reliable, and efficient machinery becomes more pronounced, ensuring that those equipped with the best tools remain at the forefront of industry innovation. By aligning purchases with strategic objectives, stakeholders can secure a tangible edge, marked by superior quality, innovative design, and operational proficiency.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products