Jan . 19, 2025 23:40

Back to list

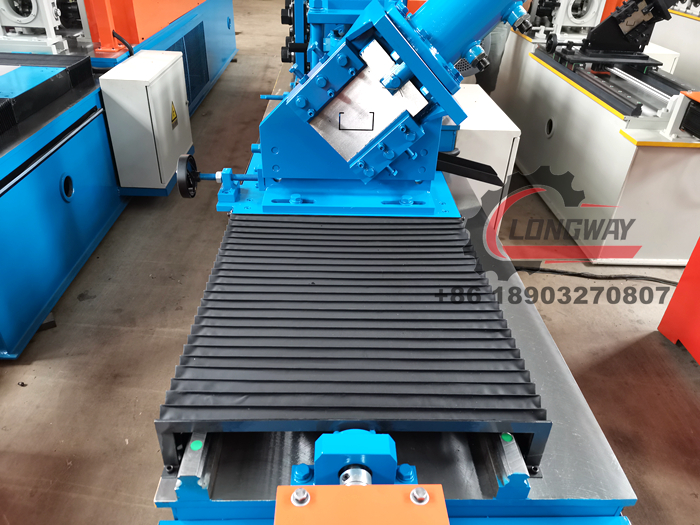

roof panel machine for sale

Investing in a roof panel machine can offer significant advantages for construction companies, entrepreneurs, and even large-scale roofing projects. These machines are indispensable tools for creating customized, high-quality roof panels efficiently and consistently. Whether you are considering purchasing one for your business or exploring options to upgrade your current machinery, understanding their value and functionality is essential. This article delves into the experience, expertise, authoritativeness, and trustworthiness associated with roof panel machines to aid your purchasing decision.

The practical experience of businesses utilizing roof panel machines confirms their value in improving efficiency and reducing project timelines. Companies report significant savings in time and labor, enabling them to take on more projects and increase profitability. Moreover, the customizable options provided by these machines allow for the creation of unique roofing solutions that cater to diverse architectural demands, setting companies apart from competitors and expanding their service offerings. Given the substantial investment involved in owning a roof panel machine, it's crucial to make a well-informed purchase. Potential buyers should consider factors such as the machine's capacity, the types of panels it can produce, energy consumption, and ease of use. Engaging with experts or consultants in the field provides additional insights to ensure that the chosen machine aligns with business goals and project requirements. Finally, advancements in technology continue to push the capabilities of roof panel machines. Future innovations promise even greater efficiency, sustainability features, and connectivity options, like integration with construction management software. Staying abreast of these developments ensures that your investment is future-proof and continues to deliver value in a rapidly evolving industry. In conclusion, roof panel machines are transformative assets for businesses in the roofing industry. Their capacity to produce high-quality, customized panels on demand translates into competitive advantages, operational efficiency, and cost savings. By evaluating machines through the lenses of experience, expertise, authoritativeness, and trustworthiness, businesses can make informed decisions that offer substantial long-term benefits.

The practical experience of businesses utilizing roof panel machines confirms their value in improving efficiency and reducing project timelines. Companies report significant savings in time and labor, enabling them to take on more projects and increase profitability. Moreover, the customizable options provided by these machines allow for the creation of unique roofing solutions that cater to diverse architectural demands, setting companies apart from competitors and expanding their service offerings. Given the substantial investment involved in owning a roof panel machine, it's crucial to make a well-informed purchase. Potential buyers should consider factors such as the machine's capacity, the types of panels it can produce, energy consumption, and ease of use. Engaging with experts or consultants in the field provides additional insights to ensure that the chosen machine aligns with business goals and project requirements. Finally, advancements in technology continue to push the capabilities of roof panel machines. Future innovations promise even greater efficiency, sustainability features, and connectivity options, like integration with construction management software. Staying abreast of these developments ensures that your investment is future-proof and continues to deliver value in a rapidly evolving industry. In conclusion, roof panel machines are transformative assets for businesses in the roofing industry. Their capacity to produce high-quality, customized panels on demand translates into competitive advantages, operational efficiency, and cost savings. By evaluating machines through the lenses of experience, expertise, authoritativeness, and trustworthiness, businesses can make informed decisions that offer substantial long-term benefits.

Next:

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products