Jan . 20, 2025 00:01

Back to list

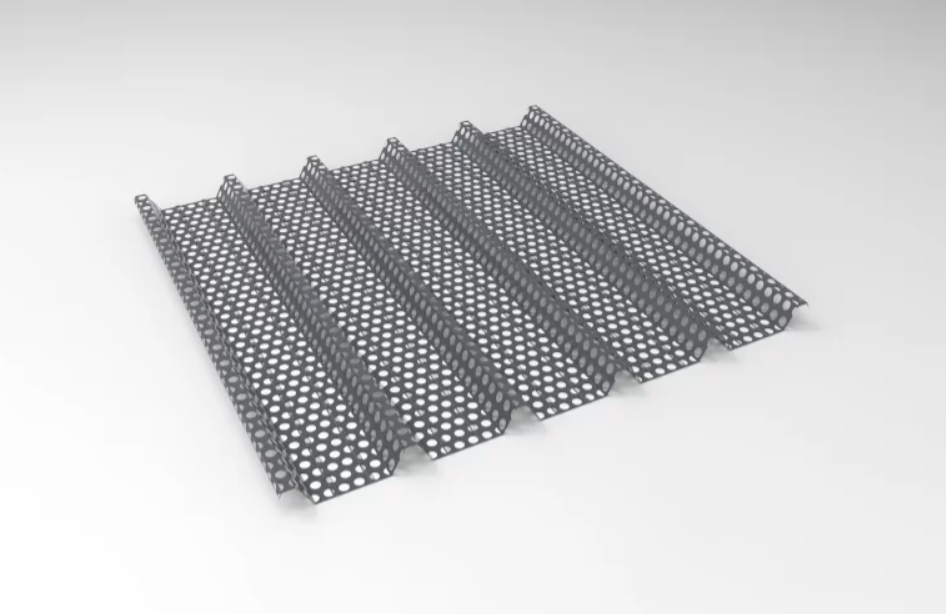

roll forming steel

Roll forming steel plays a crucial role in the contemporary manufacturing landscape, bringing precision, efficiency, and versatility to the production process. With years of extensive experience in metallurgy and mechanical engineering, the roll forming community continuously evolves to meet the demanding standards of modern construction and industrial markets.

In product development, roll forming's contribution is indispensable. The customizable nature of formed steel is a boon for designers seeking innovative solutions without sacrificing durability or cost-effectiveness. This allows manufacturers to offer their clients bespoke products, tailored to specific project needs in industries as diverse as transportation, energy, and consumer goods. Roll forming not only provides economic advantages due to its high efficiency and low material waste, but it also supports modern sustainability efforts. The process is highly efficient, leading to significant savings in both material and energy consumption. Moreover, steel's recyclability further strengthens the ecological credentials of roll forming, aligning with global trends towards greener production methodologies. To remain at the forefront of the industry, professionals continuously improve their expertise through ongoing research and development initiatives. Whether optimizing existing processes or implementing cutting-edge technologies such as AI and machine learning, the goal is always to enhance precision, speed, and flexibility. In conclusion, roll forming steel embodies a synthesis of experience, expertise, authority, and trustworthiness. This proven manufacturing process not only shapes the steel but also the future of industries reliant on strong, reliable metal components. With a dedication to innovation and quality, roll forming professionals continue to push the boundaries of what is possible, offering products that are pivotal to the advancement of technology and infrastructure worldwide.

In product development, roll forming's contribution is indispensable. The customizable nature of formed steel is a boon for designers seeking innovative solutions without sacrificing durability or cost-effectiveness. This allows manufacturers to offer their clients bespoke products, tailored to specific project needs in industries as diverse as transportation, energy, and consumer goods. Roll forming not only provides economic advantages due to its high efficiency and low material waste, but it also supports modern sustainability efforts. The process is highly efficient, leading to significant savings in both material and energy consumption. Moreover, steel's recyclability further strengthens the ecological credentials of roll forming, aligning with global trends towards greener production methodologies. To remain at the forefront of the industry, professionals continuously improve their expertise through ongoing research and development initiatives. Whether optimizing existing processes or implementing cutting-edge technologies such as AI and machine learning, the goal is always to enhance precision, speed, and flexibility. In conclusion, roll forming steel embodies a synthesis of experience, expertise, authority, and trustworthiness. This proven manufacturing process not only shapes the steel but also the future of industries reliant on strong, reliable metal components. With a dedication to innovation and quality, roll forming professionals continue to push the boundaries of what is possible, offering products that are pivotal to the advancement of technology and infrastructure worldwide.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products