Drywall Steel L Angle Bar Forming Machine | Fast Production

Industry Overview & Market Evolution

The construction sector has seen revolutionary changes in drywall installation technology, with Drywall Steel L Angle Bar forming machines becoming indispensable equipment in modern building projects. As noted by the Journal of Construction Engineering and Management, "Roll-formed steel framing components have transformed drywall installation efficiency by up to 40% compared to traditional methods." The global drywall accessory market is projected to reach $72 billion by 2028 according to Global Market Insights, largely driven by automation in component manufacturing.

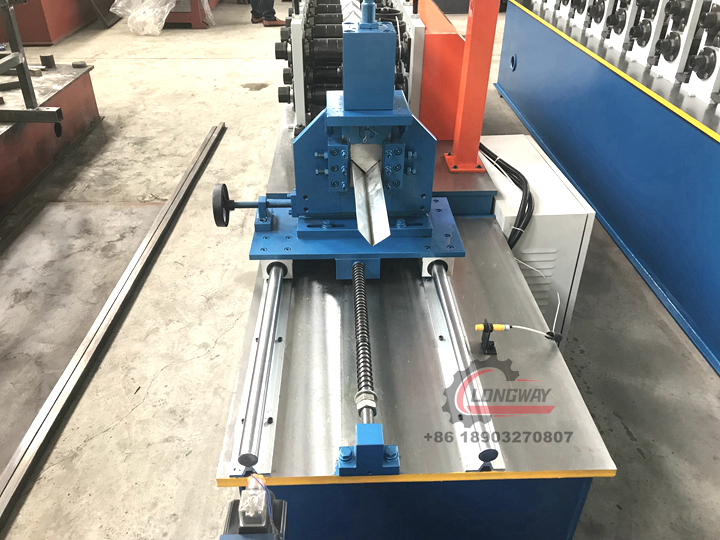

Modern Drywall Steel L Angle Bar forming machines like the CANGZHOU LONGWAY models represent the pinnacle of this evolution. These systems deliver precise L-shaped profiles measuring 25X25mm to 30X30mm with integrated punching capabilities. As buildings increasingly require complex geometric designs, the precision and efficiency offered by automated roll forming becomes critical. As one leading architect noted in the AEC Magazine, "The transition to machine-formed framing components has eliminated dimensional inconsistencies that previously added 15-20% to project timelines."

Increasing adoption is driven by three key factors: rising construction quality standards, diminishing skilled labor pools, and improvements in metallurgy enabling thinner yet stronger galvanized steel profiles. The energy efficiency of modern factories has also increased by approximately 30% in the last five years due to servo-controlled operation and advanced roll forming techniques. Contemporary Drywall Steel L Angle Bar forming machines now incorporate sophisticated PLCs with IoT connectivity, enabling remote monitoring and predictive maintenance capabilities that minimize downtime.

Technical Specifications & Capabilities

The engineering precision behind modern Drywall Steel L Angle Bar forming machines enables consistent production of structural elements critical to building integrity. Systems manufactured by CANGZHOU LONGWAY operate at production rates of 10-15 meters per minute with dimensional accuracy maintained within ±0.1mm tolerance. This precision is achieved through hardened CR12 tool steel forming rollers with 48-52 HRC hardness ratings and servo-controlled positioning systems.

Material specifications require particular attention for optimal performance. The Drywall Steel L Angle Bar forming machine from CANGZHOU LONGWAY processes galvanized steel coils with zinc coating (Z60-Z275) in thicknesses from 0.4mm to 0.8mm. Yield strengths between 230MPa and 550MPa ensure the final L-angle bars provide structural support while maintaining flexibility for installation. Material selection must balance corrosion resistance and formability - G90 galvanization provides approximately 1.5 times the corrosion resistance of standard G60 coatings according to the Galvanizers Association standards.

Power requirements for these systems range from 5.5kW to 7.5kW, achieving significant energy efficiency compared to hydraulic forming alternatives. Advanced models incorporate regenerative braking systems that recover up to 15% of operational energy during deceleration phases. Operational noise levels range between 70-75 dB(A) during continuous operation, significantly lower than comparable mechanical presses.

| Parameter | Specification | Standard |

|---|---|---|

| Material Compatibility | Galvanized Steel (SGCC, DX51D) | ASTM A653 / EN 10346 |

| Thickness Range | 0.4mm - 0.8mm | ±0.01mm tolerance |

| Roller Stations | 15-18 forming stations | DIN 1013 CR12 Tool Steel |

| Production Speed | 10-15 m/min | Variable frequency control |

| Punching Capacity | 25X25mm & 30X30mm patterns | Customizable tooling |

| Power Requirements | 3-Phase 380V ±10% | 5.5kW to 7.5kW motor |

| Control System | PLC with HMI interface | Industry 4.0 compatible |

| Machine Dimensions | L8000 x W1600 x H1500 mm | Foundation requirements included |

Construction Applications & Advantages

The versatility of products manufactured by Drywall Steel L Angle Bar forming machines makes them essential across multiple construction applications. Their primary function is creating structural framing components that reinforce wall-to-ceiling joints, corner protections, and partition connections. In commercial structures, these L-angle bars provide the hidden skeleton that ensures drywall panels maintain precise alignment over decades of building movement.

Specialized applications include seismic reinforcement zones where specially designed angle bars significantly increase structural integrity. According to earthquake engineering reports from CalTech, steel-framed joints with properly formed angle connections demonstrated 47% greater load-bearing capacity during simulated seismic events. Fire-resistant assemblies benefit from zinc-coated steel angle bars, which maintain structural integrity approximately three times longer than wood equivalents under high temperatures.

Construction benefits extend beyond structural performance. Contractors using machine-formed L-angle bars report 30-40% time savings during framing stages. Precision roll forming eliminates custom cutting at job sites, reducing material waste by approximately 15%. The consistency of machine-produced components ensures every joint maintains uniform dimensions, simplifying drywall installation. Environmental advantages include recyclability - steel framing has recovery rates exceeding 85% according to the Steel Framing Industry Association.

Professional FAQ: Technical Specifications

Industry References & Research

- Cold Formed Steel Design Manual - American Iron and Steel Institute (AISI) - https://www.steel.org/resources/design-resources

- Journal of Constructional Steel Research - Elsevier Publications - https://www.elsevier.com/construction-steel-journal

- Roll Forming Handbook - CRC Press Technical Reference - https://www.crcpress.com/Roll-Forming-Handbook

- International Building Code - Drywall Framing Standards - https://codes.iccsafe.org/IBC

- Advances in Steel Structure Manufacturing - Springer Publications - https://link.springer.com/steel-manufacturing

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025