Double Layer Roll Forming Machine For Roofing Sheet - High Efficiency & Precision

Official Website: https://www.lwrollformingmachine.com

Tel: +86 15028668612 | Mobile: +86 18903270807

Email: rebecca@longwaymachinery.com

Address: SHIBAWUXING VILLAGE BO TOWN, CANGZHOU CITY, HEBEI PROVINCE

1. Industry Overview & Trends: The Ascendancy of Double Layer Roll Forming Technology

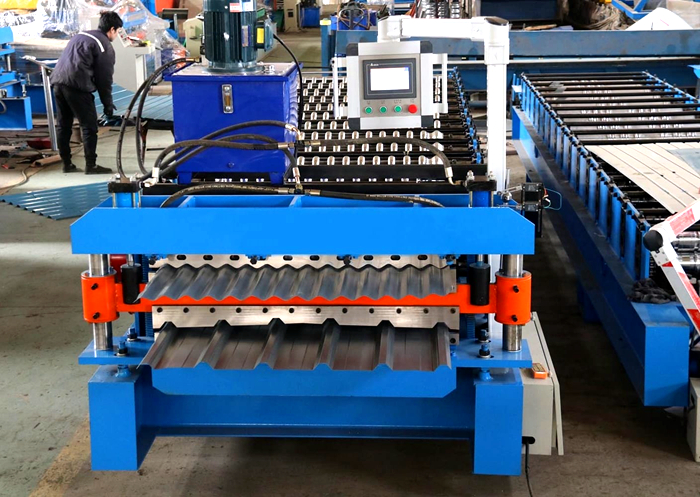

The roofing industry is experiencing an unprecedented shift towards automation and efficiency. At the heart of this evolution is the Double Layer Roll Forming Machine For Roofing Sheet, a technological marvel that has become essential for high-throughput, flexible, and precision production of metal roofing sheets with dual profile functionality.

Industry sources such as Roll Forming Magazine note the dramatic increase in demand for multi-profile forming solutions—particularly in infrastructure, prefabricated buildings, residential, and industrial construction (Roll Forming Magazine, 2023).

2. Product Introduction: What is a Double Layer Roll Forming Machine?

The Double Layer Roll Forming Machine For Roofing Sheet is engineered to streamline the production process by forming two distinct sheet profiles using a single compact machine. This dual functionality not only conserves space and investment but also enhances the versatility and responsiveness of metal sheet fabrication, adapting rapidly to market requirements.

- Production speed: 20 meters/minute

- Profiles: Two profiles in one equipment

- Applications: Widely used in industrial, commercial, residential, and agricultural buildings

- Product Url: Double Layer Roll Forming Machine For Roofing Sheet

3. Key Technical Parameters Table

| Technical Parameter | Specification / Value |

|---|---|

| Production Speed | 20m/min |

| Coil Width | 1000mm / 1200mm / Customizable |

| Material Thickness | 0.3mm – 1.0mm |

| Material Type | Galvanized Steel, Color Steel, Alumimum |

| Roller Material | 45# steel with hard chrome coating |

| Motor Power | 7.5kW – 15kW (depending on configuration) |

| Control System | PLC Automatic |

| Main Frame | 350H Beam Welded Structure |

| Dimension (L×W×H) | 9500×1650×1550mm (standard) |

| Volatge | 380V/50Hz/3Phase (or customized) |

| Weight | 8 - 10 Tons |

4. Technical Parameter Visualizations

5. Application Scenarios

- Large-scale roofing panel manufacturing plants

- Prefabricated and modular building construction

- Industrial warehouses & commercial facilities

- Residential real estate projects

- Specialized agricultural buildings

- Export processing and OEM supply chain business

6. EEAT: CANGZHOU LONGWAY — Your Authoritative Partner

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD stands out in the industry, featuring deep expertise and a solid reputation for Double Layer Roll Forming Machine For Roofing Sheet solutions. Our products undergo rigorous quality control, align with global standards (Roll Forming Equipment Market Study), and are recommended by international forums and technical publications.

Certification: ISO, CE, SGS available upon request.

Experience: 15+ years proven production and export records.

7. Professional FAQ about Double Layer Roll Forming Machines

- 1. What are the typical materials supported by a Double Layer Roll Forming Machine For Roofing Sheet?

- The machine supports GI (Galvanized Iron), PPGI (Pre-Painted Galvanized Iron), aluminum, and galvanized steel. Thickness range: 0.3–1.0mm for best forming results.

- 2. Can the profile shapes be customized?

-

Yes. Both top and bottom profiles can be customized according to the client’s CAD drawings or reference panel samples.

Source: The Fabricator - 3. What is the required installation standard?

- Installation complies with international industrial machinery standards, including leveling, anchoring, and electrical integration. On-site guidance or remote support is provided.

- 4. How does the PLC control system benefit the operation?

- The PLC (Programmable Logic Controller) system enables automatic length, batch, and profile changeover control, improving productivity and reducing operator errors.

- 5. What maintenance schedule is recommended?

- Regular lubrication (weekly), inspection of rollers and bearings (monthly), and electronic system checkup (quarterly) ensure minimal downtime and optimal output.

- 6. Which main safety features are equipped?

- Emergency stop, overload protection, and mechanical guards are standard. Optional: light curtains and IoT remote diagnostics.

- 7. What is the average lifespan of rollers and cutters?

- With appropriate steel and surface treatment (high chrome), rollers and cutters last over 5 years under daily industrial usage.

Frequently Asked Technical Questions & Answers

8. Why Choose CANGZHOU LONGWAY’s Double Layer Roll Forming Machine For Roofing Sheet?

- High Efficiency: Dual-layer, double-profile output maximizes return on investment

- Robust Structure: H-beam welded main frames ensure long term stability

- Smart Control: Fully automated PLC system with remote diagnostics capability

- Precision Engineering: Advanced roller technology delivers perfect dimensional accuracy

- Comprehensive Service: End-to-end project support, installation, and 24/7 aftersales

- Global Delivery: Efficient shipping & packaging for worldwide customers

- Custom Solutions: Tailored to your profile, speed, and application needs

9. Global Market Trends & Industry Data

According to reports from MarketsandMarkets, the global roll forming machine market is set for a CAGR of 6.4% from 2023 to 2027, driven by infrastructural growth and demand for energy-efficient, lightweight roofing solutions.

- Shift to smart factories and automated roll forming lines

- Mounting demand for quick-switch, multi-profile machines in Asia & Africa

- Sustainability and waste minimization in metal sheet manufacturing

10. Customer Success Stories

Clients worldwide—from Europe to the Middle East, Southeast Asia, and Latin America—trust the Double Layer Roll Forming Machine For Roofing Sheet by LONGWAY for its productivity, dependability, and adaptability.

Case–Middle East: A major construction contractor reduced their footprint and profile changeover downtime by 70% after adopting the dual-layer model.

Case–Asia Pacific: Modular housing providers accelerated delivery with dual-output lines, meeting custom roofing profile needs for multiple markets.

11. Contact Us for Expert Consultation

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

Phone: +86 15028668612 | Mobile: +86 18903270807

Email: rebecca@longwaymachinery.com

Official Website: www.lwrollformingmachine.com

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025