Jan . 20, 2025 08:00

Back to list

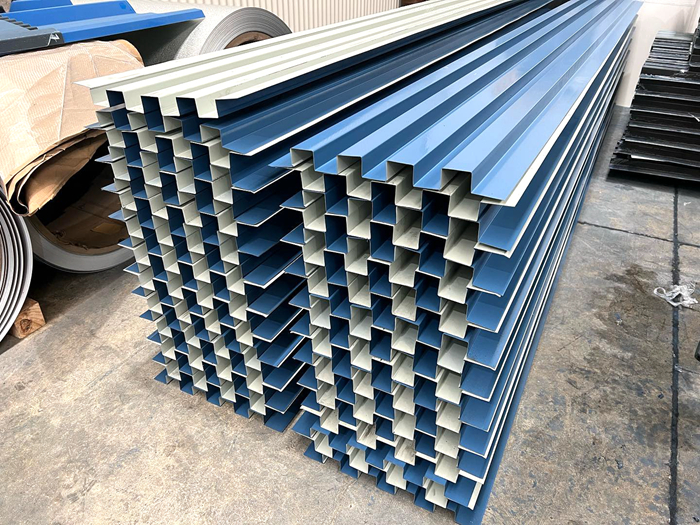

corrugated roll forming machine for sale

For businesses in the manufacturing and construction industries, finding the right equipment is crucial for maintaining efficiency and quality in production. When it comes to metal sheet shaping, the corrugated roll forming machine stands out as an indispensable asset. Finding a suitable corrugated roll forming machine for sale requires not just expertise but also a keen understanding of the market and specific industry needs.

Incorporating advanced technology into corrugated roll forming machines also offers significant benefits. Modern machines often come equipped with automated systems, enhancing precision in production and reducing manual error. Features such as Computer Numerical Control (CNC) integration enable better control over the cutting and shaping operations, ensuring that every output meets exact specifications. Environmentally conscious businesses might also consider the sustainability aspect. Machines that optimize material usage, reduce energy consumption, and minimize emissions align well with green manufacturing practices. Choosing such equipment not only reduces operational costs but also enhances corporate social responsibility credentials. The purchase decision should not end at the machine itself. Ensuring proper installation and operator training is equally important. A well-trained workforce maximizes the machine's capabilities while adhering to safety standards, which is crucial for preventing workplace accidents. Furthermore, continuous maintenance schedules must be adhered to for prolonging machine life and optimizing performance. Finally, as you navigate the plethora of options for a corrugated roll forming machine for sale, don't overlook the importance of scalability. Your business needs may grow, and investing in equipment that can expand its operations with add-on features and modules can be a strategic move. This foresight not only ensures better return on investment but also positions the business to quickly adapt to market changes and customer demands. In conclusion, selecting a corrugated roll forming machine is a decision that requires careful consideration of expertise, market knowledge, and strategic foresight. The right machine not only enhances production quality and efficiency but also aligns with broader business goals such as sustainability and scalability, ensuring a competitive edge in the industry. For those looking to invest, partnering with reputable manufacturers, leveraging technology, and committing to proper maintenance and training are all steps toward ensuring long-term success.

Incorporating advanced technology into corrugated roll forming machines also offers significant benefits. Modern machines often come equipped with automated systems, enhancing precision in production and reducing manual error. Features such as Computer Numerical Control (CNC) integration enable better control over the cutting and shaping operations, ensuring that every output meets exact specifications. Environmentally conscious businesses might also consider the sustainability aspect. Machines that optimize material usage, reduce energy consumption, and minimize emissions align well with green manufacturing practices. Choosing such equipment not only reduces operational costs but also enhances corporate social responsibility credentials. The purchase decision should not end at the machine itself. Ensuring proper installation and operator training is equally important. A well-trained workforce maximizes the machine's capabilities while adhering to safety standards, which is crucial for preventing workplace accidents. Furthermore, continuous maintenance schedules must be adhered to for prolonging machine life and optimizing performance. Finally, as you navigate the plethora of options for a corrugated roll forming machine for sale, don't overlook the importance of scalability. Your business needs may grow, and investing in equipment that can expand its operations with add-on features and modules can be a strategic move. This foresight not only ensures better return on investment but also positions the business to quickly adapt to market changes and customer demands. In conclusion, selecting a corrugated roll forming machine is a decision that requires careful consideration of expertise, market knowledge, and strategic foresight. The right machine not only enhances production quality and efficiency but also aligns with broader business goals such as sustainability and scalability, ensuring a competitive edge in the industry. For those looking to invest, partnering with reputable manufacturers, leveraging technology, and committing to proper maintenance and training are all steps toward ensuring long-term success.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products