Jan . 20, 2025 08:18

Back to list

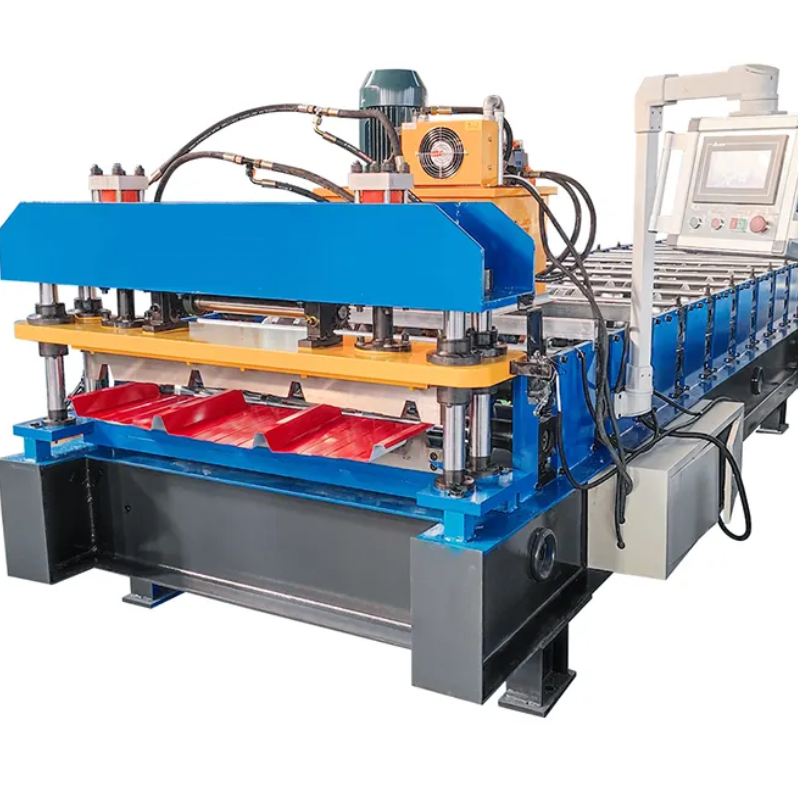

standing seam roll forming machine

The standing seam roll forming machine is a crucial innovation in the sheet metal fabrication industry, providing exceptional value and versatility for businesses specializing in constructing roofs and facades. This article explores the experience, expertise, authority, and trustworthiness encompassing the standing seam roll forming machine, ensuring a comprehensive understanding of its impact on modern construction and manufacturing.

Trustworthiness in this context extends beyond the machine's operational dependability to the broader implications of its use in the field. Manufacturers known for producing reliable standing seam roll forming machines often provide extensive technical support, training, and warranties. This commitment to customer service builds trust and fosters enduring professional relationships. Transparent communication regarding machine capabilities, limitations, and maintenance requirements further consolidates a manufacturer's reputation as a trusted industry leader. For businesses contemplating the acquisition of a standing seam roll forming machine, it's essential to consider factors like production volume, material types, and project complexity. Collaborating with established suppliers, who can provide insights based on extensive practical experience, is invaluable. These relationships can offer guidance on the latest technological advancements, enabling businesses to remain competitive and responsive to market needs. In conclusion, the standing seam roll forming machine represents a significant asset in modern construction and manufacturing, championing experience, expertise, authoritativeness, and trustworthiness. Its influence extends from enhancing productivity and precision in roof panel production to supporting sustainable building practices. By embracing this technology, businesses not only streamline their operations but also position themselves as leaders in the ever-evolving construction landscape.

Trustworthiness in this context extends beyond the machine's operational dependability to the broader implications of its use in the field. Manufacturers known for producing reliable standing seam roll forming machines often provide extensive technical support, training, and warranties. This commitment to customer service builds trust and fosters enduring professional relationships. Transparent communication regarding machine capabilities, limitations, and maintenance requirements further consolidates a manufacturer's reputation as a trusted industry leader. For businesses contemplating the acquisition of a standing seam roll forming machine, it's essential to consider factors like production volume, material types, and project complexity. Collaborating with established suppliers, who can provide insights based on extensive practical experience, is invaluable. These relationships can offer guidance on the latest technological advancements, enabling businesses to remain competitive and responsive to market needs. In conclusion, the standing seam roll forming machine represents a significant asset in modern construction and manufacturing, championing experience, expertise, authoritativeness, and trustworthiness. Its influence extends from enhancing productivity and precision in roof panel production to supporting sustainable building practices. By embracing this technology, businesses not only streamline their operations but also position themselves as leaders in the ever-evolving construction landscape.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products