Rincian Produk

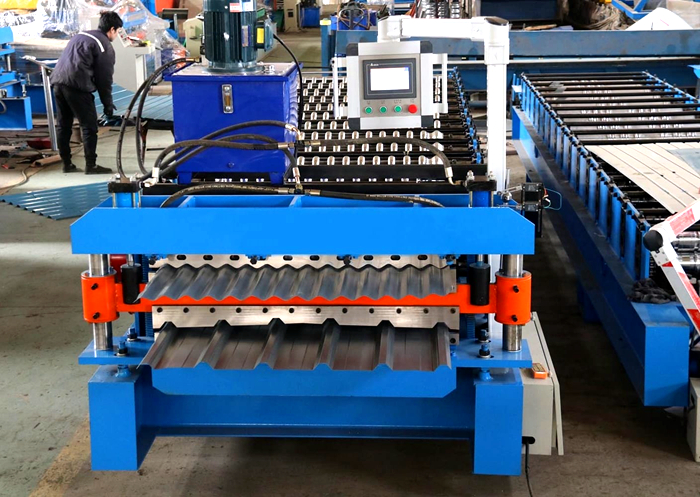

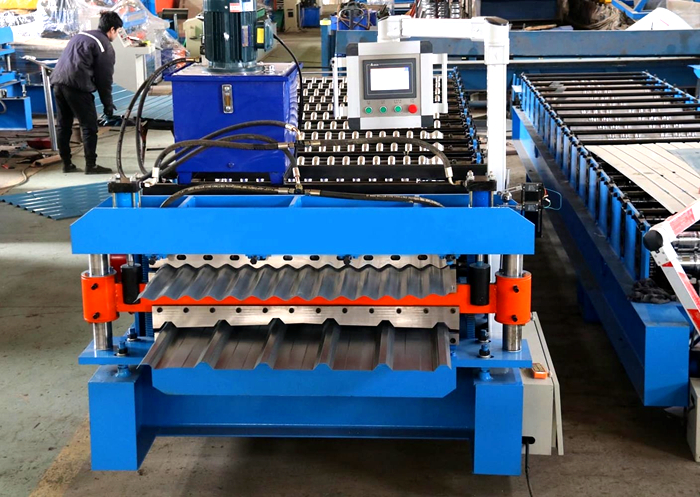

Double Layer Roll Forming Machine Introduction

Double layer roll forming machine, also called double deck roll forming machine .

With 2 layers of guiding tables and the roll forming and mesin potong memanjang, double layer roll forming machines can produce two different roofing sheets with high efficiency. Generally speaking, double layer forming machine holds the following characteristics:

Pergantian yang cepat dan mudah antara 2 profil: beroperasi pada layar PLC, tidak perlu mengubah atau menyesuaikan perkakas rol apa pun.

Saving space and cost for the users.

Kecepatan produksi: 10/20/30m/mnt opsional.

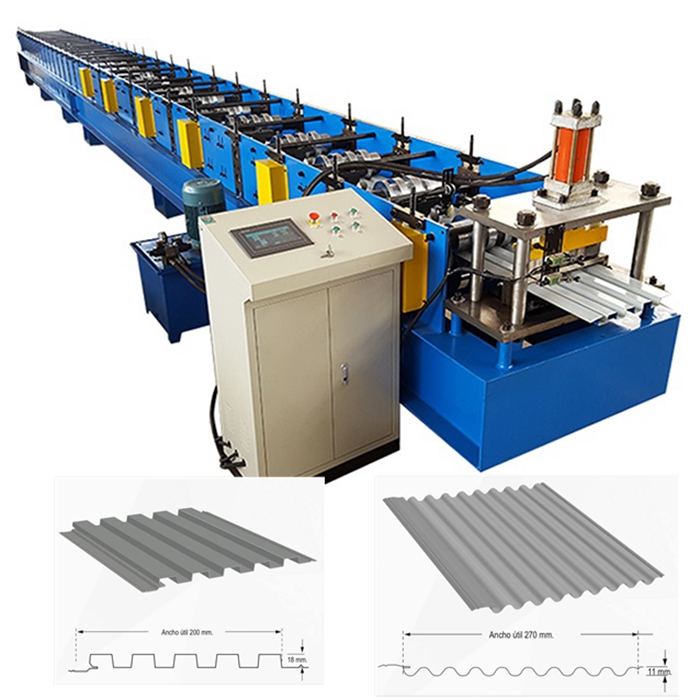

Gambar profil untuk referensi:

Roofing sheet has many different shapes. Usually different countries have their own popular design. As a roll forming equipment manufacturer, we can customize the double deck roll forming machine as customers’ demand. This double layer forming machine can work two different profiles.

Gambar profil untuk referensi:

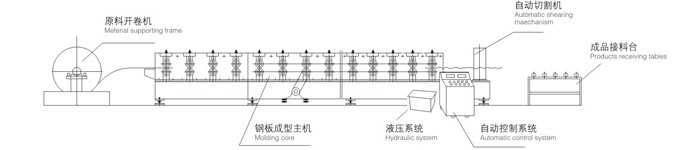

Double Layer Roll Forming Machine Working Process

Feeding: Metal coils are loaded onto the double layer roll forming machine. These coils can be made of various metals such as steel, aluminum, or copper.

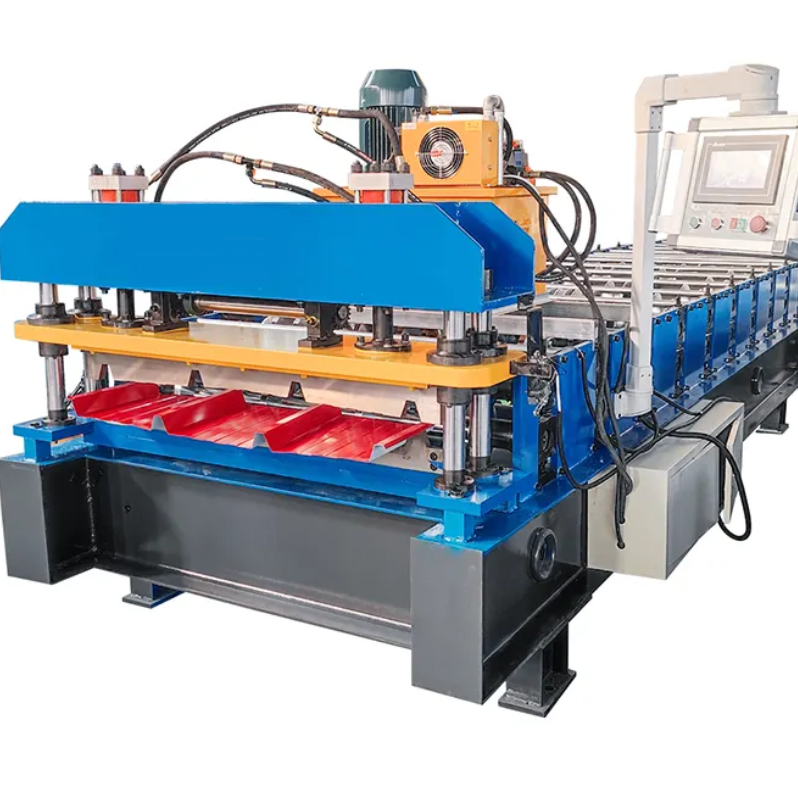

Roll Forming: The metal coils pass through a series of rollers, each set of rollers responsible for shaping the metal into the desired profile. In a double deck roll forming machine, there are typically two sets of rollers, each forming a different profile.

Cutting: Once the metal has been formed into the desired shapes, it is cut to the required length by a cutting mechanism integrated into the machine.

Stacking or Collecting: The finished metal profiles are then either stacked for further processing or collected for packaging and shipping.

These double layer forming machines are used in various industries where there is a need for mass production of metal components with different profiles. Applications include roofing, wall cladding, automotive parts, and many others.

Double Layer Roll Forming Machine Applications

A double layer forming machine has a wide range of applications across various industries where there is a need for mass production of metal components with different profiles.

1. Roofing and Cladding: Double layer forming machines are extensively used in the construction industry for manufacturing metal roofing sheets and wall cladding panels. These machines can produce different profiles simultaneously, allowing for customization and versatility in design.

2. Automotive Industry: In the automotive sector, double layer forming machines are used to produce various components such as body panels, chassis parts, and trim pieces. The ability to form multiple layers simultaneously enables the efficient production of complex shapes required in vehicle manufacturing.

3. Furniture and Appliances: Metal components used in furniture and appliances, such as cabinets, shelves, and enclosures, can be manufactured using double layer forming machines. These double layer roll forming machines offer high precision and repeatability, making them suitable for producing components with tight tolerances.

4. Storage Systems: Double deck rool forming machines are employed in the fabrication of storage systems like shelving units, racks, and pallets used in warehouses, distribution centers, and retail stores.

5. Solar Panel Mounting Structures: With the growing demand for renewable energy solutions, double layer forming machines are utilized to manufacture mounting structures for solar panels. These structures require precise profiles to ensure optimal performance and durability, which can be achieved efficiently with such machines.

6. Agricultural Equipment: Components for agricultural machinery such as grain bins, silos, and equipment enclosures can be produced using double layer roll forming machines. These machines enable manufacturers to efficiently produce durable and weather-resistant components essential for agricultural operations.

Farameter Teknis

Proses kerja

Uncoiling → Memberi makan bahan ke dalam mesin → Membentuk gulungan → Pemotongan hidrolik → Meja penerima produk

|

Bahan baku |

Jenis Koil |

PPGI, PPGL, GI |

|

Lebar |

1000/1200/1220mm |

|

|

Kisaran ketebalan |

Pengukur 29-22 (0,3-0,6 mm) |

|

|

Kebutuhan Daya

|

Tegangan |

380v/3ph/50hz (Disesuaikan) |

|

Tenaga Motor Utama |

5.5kw |

|

|

Kekuatan pemotong |

4kw |

|

|

Kecepatan pembentukan |

15-20 m/mnt |

|

|

Rangka Mesin |

Struktur Balok 350mm H |

|

|

Ketebalan struktur |

Pelat Penopang Tengah Baja Dilas 18 mm |

|

|

Membentuk poros |

Poros padat 75mm dengan perlakuan panas |

|

|

Bahan Rol |

Baja Tempa 45 # Kelas Tinggi |

|

|

Membentuk stasiun |

14-18 baris Rolling Type: Konsep desain rolling terpisah, Ini dapat melepaskan tekanan internal dari fheets, Kemudian lembaran akan dalam kondisi yang baik dan presisi tinggi |

|

|

Cara Transmisi |

Penggerak rantai 1 inci (Rantai Ganda) |

|

|

Jenis pemotongan |

Jenis Pilar Hidraulik dan pemotongan yang diatur panjang |

|

|

Sistem pengaturan |

PLC Delta dan Inverter Delta |

|

|

Layar |

Layar sentuh |

|

|

Dimensi (Perkiraan) |

8,8m×1,5m×1,2m |

|

|

Total berat (Perkiraan) |

7.6T |

|

Gambar Detail Mesin

Setiap komponen dapat dirancang sesuai kebutuhan khusus. Mesin roll forming panjang menyediakan OEM / ODM untuk semua pelanggan

Aplikasi

Aplikasi Mesin Roll Forming Panel Atap

Rangkaian profil ini dirancang untuk menjadi panel atap yang ekonomis untuk proyek perumahan, industri, dan komersial.

Minimum 0,30mm dan maksimum 0,7mm memberikan ketahanan lebih terhadap kerusakan.

Mesin Terkait

Pelanggan berharga JAUH

-

Chili

-

lran

-

Filipina

-

Afrika Selatan

Paket dan Pengiriman

1. Menyemprotkan minyak anti-korosif pada rol untuk mencegah oksidasi rol selama pengiriman

2.Packaging film isolasi seluruh mesin untuk mencegah oksidasi mesin selama pengiriman

3. Perencanaan ruang yang masuk akal untuk mengurangi biaya transportasi bagi pelanggan

4. Memperbaiki dengan baik untuk mencegah kerusakan mesin selama masa transit

Tampilan Pabrik