detalji o proizvodu

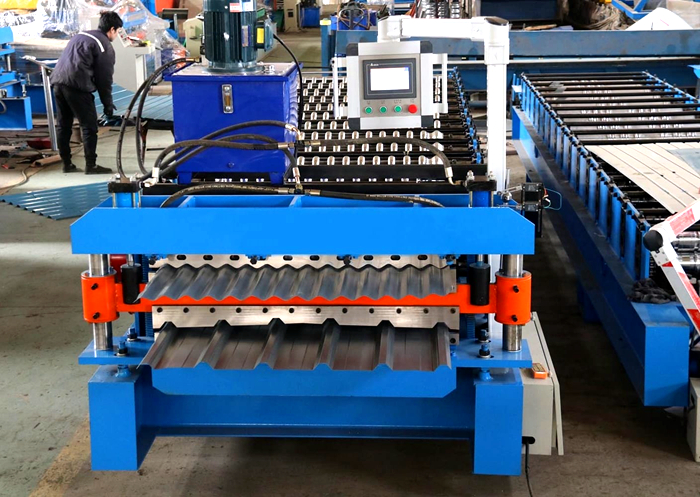

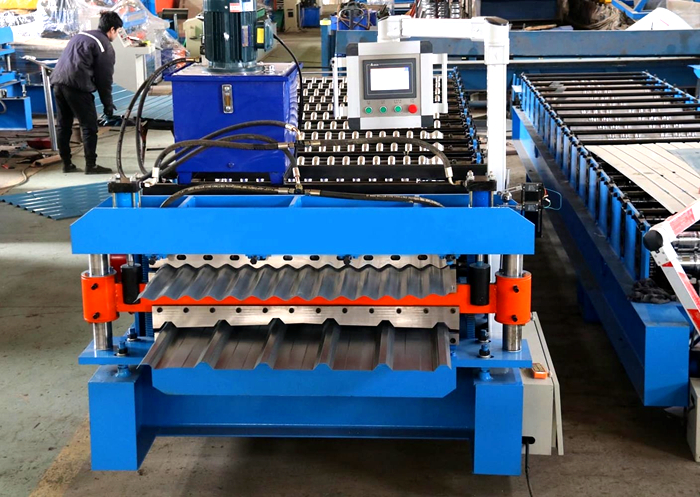

Double Layer Roll Forming Machine Introduction

Double layer roll forming machine, also called double deck roll forming machine .

With 2 layers of guiding tables and the roll forming and stroj za rezanje na duljinu, double layer roll forming machines can produce two different roofing sheets with high efficiency. Generally speaking, double layer forming machine holds the following characteristics:

Brzo i jednostavno prebacivanje između 2 profila: rad na PLC zaslonu, nema potrebe mijenjati ili podešavati alate za valjke.

Saving space and cost for the users.

Brzina proizvodnje: 10/20/30m/min izborno.

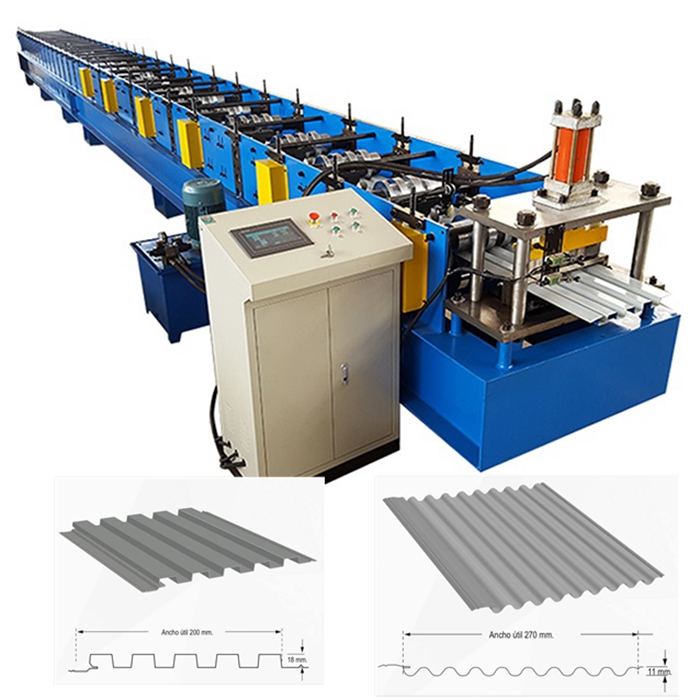

Crtež profila za referencu:

Roofing sheet has many different shapes. Usually different countries have their own popular design. As a roll forming equipment manufacturer, we can customize the double deck roll forming machine as customers’ demand. This double layer forming machine can work two different profiles.

Crtež profila za referencu:

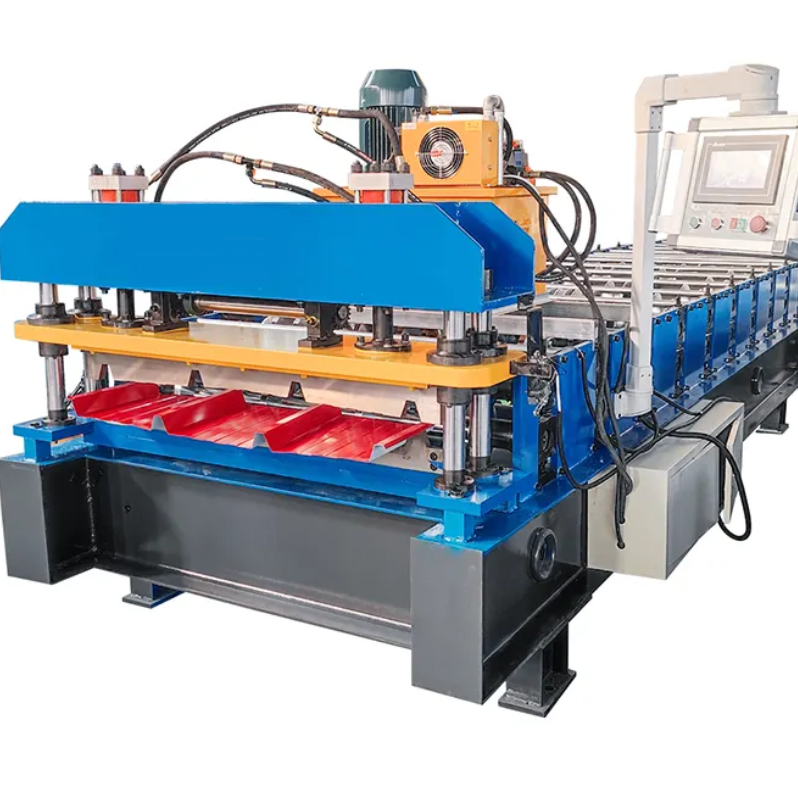

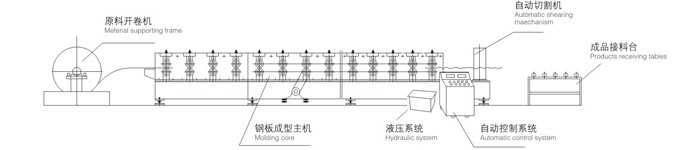

Double Layer Roll Forming Machine Working Process

Feeding: Metal coils are loaded onto the double layer roll forming machine. These coils can be made of various metals such as steel, aluminum, or copper.

Roll Forming: The metal coils pass through a series of rollers, each set of rollers responsible for shaping the metal into the desired profile. In a double deck roll forming machine, there are typically two sets of rollers, each forming a different profile.

Cutting: Once the metal has been formed into the desired shapes, it is cut to the required length by a cutting mechanism integrated into the machine.

Stacking or Collecting: The finished metal profiles are then either stacked for further processing or collected for packaging and shipping.

These double layer forming machines are used in various industries where there is a need for mass production of metal components with different profiles. Applications include roofing, wall cladding, automotive parts, and many others.

Double Layer Roll Forming Machine Applications

A double layer forming machine has a wide range of applications across various industries where there is a need for mass production of metal components with different profiles.

1. Roofing and Cladding: Double layer forming machines are extensively used in the construction industry for manufacturing metal roofing sheets and wall cladding panels. These machines can produce different profiles simultaneously, allowing for customization and versatility in design.

2. Automotive Industry: In the automotive sector, double layer forming machines are used to produce various components such as body panels, chassis parts, and trim pieces. The ability to form multiple layers simultaneously enables the efficient production of complex shapes required in vehicle manufacturing.

3. Furniture and Appliances: Metal components used in furniture and appliances, such as cabinets, shelves, and enclosures, can be manufactured using double layer forming machines. These double layer roll forming machines offer high precision and repeatability, making them suitable for producing components with tight tolerances.

4. Storage Systems: Double deck rool forming machines are employed in the fabrication of storage systems like shelving units, racks, and pallets used in warehouses, distribution centers, and retail stores.

5. Solar Panel Mounting Structures: With the growing demand for renewable energy solutions, double layer forming machines are utilized to manufacture mounting structures for solar panels. These structures require precise profiles to ensure optimal performance and durability, which can be achieved efficiently with such machines.

6. Agricultural Equipment: Components for agricultural machinery such as grain bins, silos, and equipment enclosures can be produced using double layer roll forming machines. These machines enable manufacturers to efficiently produce durable and weather-resistant components essential for agricultural operations.

Tehnički farametri

Radni proces

Odmotavanje → Ubacivanje materijala u stroj → Oblikovanje valjaka → Hidrauličko rezanje → Stol za prijem proizvoda

|

Sirovina |

Vrsta zavojnice |

PPGI, PPGL, GI |

|

Širina |

1000/1200/1220 mm |

|

|

Raspon debljina |

29-22 mjerač (0,3-0,6 mm) |

|

|

Zahtjevi za napajanje

|

napon |

380v/3ph/50hz (prilagođeno) |

|

Snaga glavnog motora |

5,5kw |

|

|

Snaga rezača |

4kw |

|

|

Brzina oblikovanja |

15-20m/min |

|

|

Okvir stroja |

Struktura H grede od 350 mm |

|

|

Debljina strukture |

Srednja potporna ploča od zavarenog čelika od 18 mm |

|

|

Osovina za oblikovanje |

75 mm čvrsta osovina s toplinskom obradom |

|

|

Materijal valjaka |

Kovani čelik visoke kvalitete 45# |

|

|

Formiranje stanica |

14-18 redaka Vrsta valjanja: odvojeni koncept dizajna valjanja, može osloboditi unutarnje naprezanje iz listova, tada će ploča biti u dobroj formi i visoke preciznosti |

|

|

Put prijenosa |

Lančani pogon 1 inča (dvostruki lanac) |

|

|

Vrsta rezanja |

Hidraulički stup i rezanje po dužini |

|

|

Kontrolni sustav |

PLC Delta i Inverter Delta |

|

|

Zaslon |

Ekran na dodir |

|

|

Dimenzija (približno) |

8,8m×1,5m×1,2m |

|

|

Ukupna težina (približno) |

7.6T |

|

Detaljne slike stroja

Svaka komponenta može biti dizajnirana prema zahtjevima korisnika. Longway stroj za oblikovanje valjaka pruža OEM/ODM za sve kupce

Prijave

Primjena stroja za oblikovanje krovnih ploča

Ova serija profila dizajnirana je kao ekonomični krovni paneli za stambene, industrijske i komercijalne projekte.

Najmanje 0,30 mm i najviše 0,7 mm daje veću otpornost na oštećenja.

Povezani strojevi

LONGWAY vrijedan kupac

-

Čile

-

lran

-

filipinski

-

Južna Afrika

Paket i dostava

1 .Prskanje antikorozivnog ulja na valjke kako bi se spriječila oksidacija valjaka tijekom transporta

2. Izolacijska folija za pakiranje cijelog stroja kako bi se spriječila oksidacija stroja tijekom transporta

3.Razumno planiranje prostora za smanjenje troškova prijevoza za kupce

4. Dobro fiksiran kako bi se spriječilo oštećenje stroja tijekom razdoblja prijevoza

Tvornički zaslon